Ngokuqwashisa okwandayo kokuvikelwa kwemvelo, ukuthuthukiswa kanye nokugqugquzelwa kwamandla amasha emhlabeni wonke kwenze ukukhuthazwa kanye nokusetshenziswa kwezimoto zamandla kuseduze. Ngasikhathi sinye, izidingo zokuthuthukiswa okungasindi kwezinto zezimoto, ukusetshenziswa okuphephile kwama-alloys e-aluminium, nekhwalithi yawo engaphezulu, ubukhulu kanye nezakhiwo zemishini ziya ngokuya ziba phezulu. Ukuthatha i-EV enesisindo semoto esingu-1.6t njengesibonelo, i-aluminium alloy material ilinganiselwa ku-450kg, ibalwa cishe ngama-30%. Ukulimala okungaphezulu okuvela ohlelweni lokukhiqiza i-extrusion, ikakhulukazi inkinga yokusanhlamvu okumahhadlahhadla endaweni yangaphakathi nengaphandle , kuthinta kakhulu inqubekelaphambili yokukhiqizwa kwamaphrofayili e-aluminium futhi kube umgoqo wokuthuthukiswa kwesicelo sabo.

Kumaphrofayili angeziwe, ukwakheka kanye nokukhiqizwa kwe-extrusion dies kubaluleke kakhulu, ngakho ucwaningo nokuthuthukiswa kwe-dies for EV aluminium profiles kubalulekile. Ukuphakamisa izixazululo zesayensi neziphusile kungathuthukisa izinga elifanelekayo kanye nokukhiqiza kwe-extrusion yamaphrofayela e-aluminium ye-EV ukuze kuhlangatshezwane nesidingo semakethe.

1 Amazinga Omkhiqizo

(1) Izinto zokwakha, ukwelapha okungaphezulu kanye nokunqanda ukugqwala kwezingxenye nezingxenye kuzothobelana nezinhlinzeko ezifanele ze-ETS-01-007 “Izimfuneko Zobuchwepheshe Zezingxenye Zephrofayela Ye-Aluminium Alloy” kanye ne-ETS-01-006 “Izimfuneko Zobuchwepheshe Zokwelashwa Kwe-Anodic Oxidation Surface”.

(2) Ukwelashwa kwendawo: I-anodic oxidation, indawo engaphezulu akufanele ibe nezinhlamvu ezimahhadla.

(3) Ubuso bezingxenye akuvunyelwe ukuba nokukhubazeka okufana nokuqhekeka kanye nemibimbi. Izingxenye azivunyelwe ukuthi zingcoliswe ngemva kwe-oxidation.

(4) Izinto ezivinjelwe zomkhiqizo zihlangabezana nezimfuneko ze-Q/JL J160001-2017 “Izimfuneko Zezinto Ezivinjelwe Nezikhawulelwe Ezingxenyeni Zezimoto Nezinto Zokusebenza”.

(5) Izidingo zokusebenza kwemishini: amandla aqinile ≥ 210 MPa, amandla okukhiqiza ≥ 180 MPa, ubude ngemva kokuphuka kwe-A50 ≥ 8%.

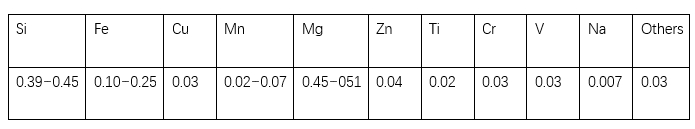

(6) Izidingo zokwakheka kwe-aluminium alloy ezimotweni zamandla amasha ziboniswa kuThebula 1.

2 Ukuhlaziya nokuhlaziya okuqhathanisayo kwesakhiwo se-extrusion die Ukunqanyulwa kwamandla amakhulu kwenzeka

(1) Isixazululo sendabuko 1: okungukuthi, ukuthuthukisa i-front extrusion die design, njengoba kuboniswe ku-Figure 2. Ngokombono ojwayelekile wokuklama, njengoba kuboniswe umcibisholo esithombeni, indawo yombambo ophakathi nendawo yokukhipha amanzi angaphansi kolimi kuyacutshungulwa, ama-drainage aphezulu naphansi angama-20 ° ngakolunye uhlangothi, futhi ukuphakama kwe-drainage H15 mm i-riten ingxenye isetshenziselwa ukuhlinzeka nge-molluminum. Ummese ongenalutho ongaphansi kolimi udluliselwa nge-engeli elungile, futhi i-aluminium encibilikisiwe ihlala ekhoneni, okulula ukukhiqiza izindawo ezifile nge-aluminium slag. Ngemva kokukhiqiza, kuqinisekiswa nge-oxidation ukuthi indawo engaphezulu ijwayele kakhulu ukuba nezinkinga zokusanhlamvu ezimahhadla.

Ukulungiselela okulandelayo kwenziwa enqubweni evamile yokukhiqiza isikhunta:

a. Ngokusekelwe kulesi sikhunta, sizame ukwandisa ukunikezwa kwe-aluminium ezimbanjeni ngokuphakela.

b. Ngokwesisekelo sokujula kwasekuqaleni, ukujula kommese ongenalutho ongaphansi kolimi kuyajula, okungukuthi, u-5mm wengezwe ku-15mm wokuqala;

c. Ububanzi beblade engenalutho yolimi olungaphansi bunwetshwa ngo-2mm ngokusekelwe ku-14mm yasekuqaleni. Isithombe sangempela ngemva kokwenza kahle siboniswa kuMfanekiso 3.

Imiphumela yokuqinisekisa ibonisa ukuthi ngemva kokuthuthukiswa okuthathu okungenhla okungenhla, ukukhubazeka okusanhlamvu okumahhadla kusekhona kumaphrofayela ngemva kokwelashwa kwe-oxidation futhi akukaxazululwa ngokunengqondo. Lokhu kubonisa ukuthi uhlelo lokuqala lokuthuthukisa namanje alukwazi ukuhlangabezana nezidingo zokukhiqiza zezinto ezixubile ze-aluminium zama-EVs.

(2) Uhlelo olusha lwesi-2 lwahlongozwa ngokusekelwe ekuthuthukisweni kokuqala. Idizayini yesikhunta ye-New Scheme yesi-2 ikhonjiswe kuMfanekiso 4. Ngokusho "komgomo wokuguquguquka kwensimbi" kanye "nomthetho wokumelana okuncane", isikhunta sezingxenye zezimoto esithuthukisiwe samukela uhlelo lokuklama "imbobo engemuva evulekile". Ukuma kwezimbambo kudlala indima ekuthinteni okuqondile futhi kunciphisa ukumelana nokungqubuzana; indawo yokuphakelayo iklanyelwe ukuba "imise okwemboza yebhodwe" futhi indawo yebhuloho icutshungulwa ibe uhlobo lwe-amplitude, inhloso ukunciphisa ukumelana nokungqubuzana, ukuthuthukisa ukuhlangana, nokunciphisa ingcindezi ye-extrusion; ibhuloho lishiswe ngangokunokwenzeka ukuze kuvinjelwe inkinga yezinhlamvu eziqinile phansi kwebhuloho, futhi ububanzi bommese ongenalutho ngaphansi kolimi lwebhuloho phansi ≤3mm; umehluko wesinyathelo phakathi kwebhande elisebenzayo kanye nebhande eliphansi elisebenzayo ngu-≤1.0mm; ummese ongenalutho ngaphansi kolimi oluphezulu olufayo lubushelelezi futhi luguquguquke ngokulinganayo, ngaphandle kokushiya umgoqo wokugeleza , futhi umgodi wokwakha ushaywa ngokuqondile ngangokunokwenzeka; ibhande elisebenzayo phakathi kwamakhanda amabili ebambo elingaphakathi eliphakathi lifushane ngangokunokwenzeka, ngokuvamile lithatha inani eliphindwe izikhathi ezingu-1.5 kuya kwezingu-2 ubukhulu bodonga; i-drainage groove inenguquko ebushelelezi ukuze ihlangabezane nesidingo samanzi ensimbi eyanele ye-aluminium ageleza emgodini, ethula isimo esihlanganiswe ngokugcwele, futhi ingashiyi indawo efile kunoma iyiphi indawo (ummese ongenalutho ngemuva kwefa elingaphezulu aweqi ku-2 kuya ku-2.5mm). Ukuqhathaniswa kwesakhiwo se-extrusion die ngaphambi nangemuva kokuthuthukiswa kuboniswa kuMfanekiso 5.

(3) Naka ukuthuthukiswa kwemininingwane yokucubungula. Isikhundla sebhuloho siphucuziwe futhi sixhunywe kahle, amabhande asebenzayo aphezulu naphansi aphansi, ukumelana nokuguqulwa kuyancipha, futhi ukugeleza kwensimbi kuyathuthukiswa ukuze kuncishiswe ukuguqulwa okungalingani. Ingakwazi ukucindezela ngokuphumelelayo izinkinga ezifana nezinhlamvu ezimahhadla nokushisela, ngaleyo ndlela iqinisekise ukuthi indawo yokukhipha izimbambo kanye nesivinini sempande yebhuloho kuhambisana nezinye izingxenye, kanye nezinkinga zangaphezulu ezicindezela ngokunengqondo nangokwesayensi njengokushisela okusanhlamvu okumahhadlahhadla ebusweni bephrofayela ye-aluminium . Ukuqhathanisa ngaphambi nangemva kokuthuthukiswa kokukhishwa kwesikhunta kuboniswe kuMfanekiso 6.

3 Inqubo yokukhipha

Ku-6063-T6 i-aluminium alloy ye-EVs, isilinganiso se-extrusion ye-split die sibalwa sibe ngu-20-80, futhi isilinganiso se-extrusion salokhu kwaziswa kwe-aluminium emshinini we-1800t singu-23, esihlangabezana nezidingo zokusebenza zokukhiqiza zomshini. Inqubo ye-extrusion ikhonjiswe kuThebula 2.

Ithebula 2 Inqubo yokukhiqiza i-Extrusion yamaphrofayili e-aluminium yokufaka imishayo yamaphakethe ebhethri e-EV

Naka amaphuzu alandelayo lapho ukhipha:

(1) Akuvunyelwe ukushisa isikhunta esithandweni esifanayo, ngaphandle kwalokho izinga lokushisa lesikhunta lizobe lingalingani futhi i-crystallization izokwenzeka kalula.

(2) Uma ukuvala okungavamile kwenzeka ngesikhathi senqubo ye-extrusion, isikhathi sokuvala akumele sidlule imizuzu emi-3, ngaphandle kwalokho isikhunta kufanele sisuswe.

(3) Akuvunyelwe ukubuyela esithandweni ukuyofudumeza bese ukhipha ngokuqondile ngemva kokubhidliza.

4. Izinyathelo zokulungisa isikhunta nokusebenza kwazo

Ngemuva kokulungiswa kwesikhunta okuningi kanye nokuthuthukiswa kwesikhunta sesilingo, uhlelo olulandelayo lokulungisa isikhunta luyaphakanyiswa.

(1) Yenza ukulungiswa kokuqala kanye nokulungiswa kwesikhunta sokuqala:

① Zama ukucwilisa ibhuloho ngangokunokwenzeka, futhi ububanzi ngezansi kwebhuloho kufanele bube ngu-≤3mm;

② Umehluko wesinyathelo phakathi kwebhande elisebenzayo lekhanda kanye nebhande elisebenzayo lesikhunta esiphansi kufanele sibe ≤1.0mm;

③ Ungashiyi i-flow block;

④ Ibhande elisebenzayo phakathi kwamakhanda amabili wesilisa ezimbanjeni zangaphakathi kufanele libe lifushane ngangokunokwenzeka, futhi ukuguqulwa komsele wokudonsa amanzi kufanele kube bushelelezi, kube kukhulu futhi kubushelelezi ngangokunokwenzeka;

⑤ Ibhande elisebenzayo lesikhunta esiphansi kufanele libe lifushane ngangokunokwenzeka;

⑥ Ayikho indawo efile okufanele ishiywe kunoma iyiphi indawo (ummese ongenalutho ongemuva akufanele udlule u-2mm);

⑦ Lungisa isikhunta esingenhla ngezinhlamvu ezimahhadlahhadla endaweni engaphakathi, nciphisa ibhande elisebenzayo lesikhunta esiphansi futhi unciphise ibhulokhi yokugeleza, noma ungabi ne-flow block futhi ufinyeze ibhande elisebenzayo lesikhunta esiphansi.

(2) Ngokusekelwe ekuguqulweni okuqhubekayo kwesikhunta kanye nokuthuthukiswa kwesikhunta esingenhla, ukuguqulwa kwesikhunta okulandelayo kwenziwa:

① Susa izindawo ezifile zamakhanda amabili amadoda;

② Khipha ibhulokhi yokugeleza;

③ Yehlisa umehluko wobude phakathi kwekhanda nendawo yokusebenza ephansi;

④ Fushanisa indawo yokusebenza ephansi.

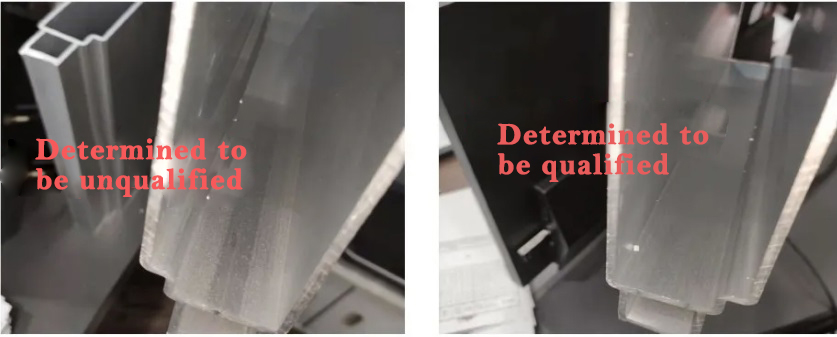

(3) Ngemva kokuba isikhunta sesilungisiwe futhi sithuthukisiwe, ikhwalithi yangaphezulu yomkhiqizo oqediwe ifinyelela esimweni esifanele, esinendawo ekhanyayo futhi engenazo izinhlamvu eziqinile, ezixazulula ngokuphumelelayo izinkinga zokusanhlamvu okuqinile, i-welding kanye nezinye iziphambeko ezikhona ebusweni bephrofayili ye-aluminium ye-EVs.

(4) Ivolumu yokukhipha inyuke isuka ku-5 t/d yaya ku-15 t/d, ithuthukisa kakhulu ukusebenza kahle kokukhiqiza.

5 Isiphetho

Ngokwandisa ngokuphindaphindiwe nokwenza ngcono isikhunta sokuqala, inkinga enkulu ehlobene nokusanhlamvu okumahhadlahhadla okungaphezulu kanye nokushisela amaphrofayili e-aluminium yama-EVs yaxazululwa ngokuphelele.

(1) Isixhumanisi esibuthakathaka sesikhunta sokuqala, umugqa wokuma kombambo omaphakathi, sathuthukiswa ngokunengqondo. Ngokuqeda izindawo ezifile zamakhanda amabili, ukwenza isicaba ibhulokhi yokugeleza, ukunciphisa umehluko wokuphakama phakathi kwekhanda nendawo yokusebenza ephansi, kanye nokunciphisa indawo yokusebenza ephansi, ukukhubazeka okungaphezulu kwengxube ye-aluminium engu-6063 esetshenziswa kulolu hlobo lwemoto, okufana nezinhlamvu ezimahhadla nokushisela, kunqotshwe ngempumelelo.

(2) Ivolumu ye-extrusion inyuke isuka ku-5 t/d yaya ku-15 t/d, ithuthukisa kakhulu ukusebenza kahle kokukhiqiza.

(3) Leli cala eliyimpumelelo lokuklanywa nokukhiqizwa kwe-extrusion limele futhi lingabhekisela ekukhiqizweni kwamaphrofayela afanayo futhi lifanele ukukhushulwa.

Isikhathi sokuthumela: Nov-16-2024