Ekuthuthukisweni kwemboni yokucubungula i-aluminium, ubuchwepheshe bokuhluzwa okusanhlamvu buhlale budlala indima ebalulekile ekunqumeni ikhwalithi yomkhiqizo nokusebenza kahle kokukhiqiza. Kusukela kwasungulwa indlela yokuhlola ye-Tp-1 yokuhlanza okusanhlamvu ngo-1987, imboni sekuyisikhathi eside ihlushwa izinselele eziqhubekayo-ikakhulukazi, ukungazinzi kwezihlungi zokusanhlamvu ze-Al-Ti-B kanye namazinga aphezulu okwengezwa adingekayo ukuze kugcinwe ukusebenza kokucwenga. Kwaze kwafika ngo-2007 lapho uguquko lwezobuchwepheshe olwaqalwa elabhorethri lwashintsha ngokuyisisekelo umzila wezinqubo zokuphonsa i-aluminium.

Ngokuthuthuka kwayo kwe-Optifine super grain refine, i-MQP izuze ukugxuma kwe-quantum ekusebenzeni kahle kokucwengwa. Yamukela umqondo omusha wokuthi "okuncane kungaphezulu," i-MQP inikeze abakhiqizi be-aluminium emhlabeni wonke indlela entsha ebheke ekwehlweni kwezindleko kanye nokwenza ngcono ukusebenza kahle. Lesi sihloko sidingida ekuziphendukeleni kwemvelo kwezobuchwepheshe, izimiso zesayensi, izinhlelo zokusebenza zomhlaba wangempela, kanye nombono wesikhathi esizayo womkhiqizo oguquguqukayo we-MQP, ebonisa ukuthi iwachaze kanjani kabusha amazinga embonini.

I. Ukuphumelela Kwezobuchwepheshe: Kusukela Emikhawulweni Ye-Opticast ukuya Ekuzalweni Kwe-Super Refiner

Yonke impumelelo enkulu yesayensi iqala ngokuhlolwa kabusha okubalulekile kobuhlakani obujwayelekile. Ngo-2007, uDkt. Rein Vainik, ecabanga ngeshumi leminyaka lomsebenzi ne-Opticast process optimization technology for grain refinement, wabhekana neqiniso elinzima: naphezu kwesithembiso salo, inqubo yehlulekile ukunqoba inkinga eqhubekayo yokusebenza kokucwenga okungazinzile emazingeni aphansi okwengezwa kwezihlungi zokusanhlamvu ze-Al-Ti-B.

I-Opticast yakhelwe phezu komqondo obonakala uphelele—ilungisa izilinganiso zokwengezwa kwesicwengisisi ngokusekelwe ezinhlotsheni zengxubevange nokuqukethwe kwe-scrap ukuze kuzuzwe ukulawula umthamo ophansi onembile. Kodwa-ke, impendulo yomsebenzisi iveze ngokungaguquguquki ukuthi izilinganiso eziphansi zokungezwa kwe-Al-Ti-B bezihlaleka okwesikhashana kuphela. Lapho ushintsho lwe-wire spool lwenzekile, ukukhuhla okusanhlamvu kwalandela ngokushesha. Lokhu kunqanyulwa kuphoqe uDkt. Vainik ukuthi aphinde avakashele udaba oluwumgogodla. Indlela esetshenziswayo igxile kuphela ezintweni eziguquguqukayo zengxubevange, ingakunaki ukuhlukahluka kwamandla angaphakathi okucwenga esicwengisi sokusanhlamvu. Eqinisweni, ukuntuleka kokulinganisa kwakho kokubili okuguquguqukayo kunikeze lokho okubizwa ngokuthi “ukulawula ukunemba” okungeyona into engaphezu kwenkohliso yaselabhorethri.

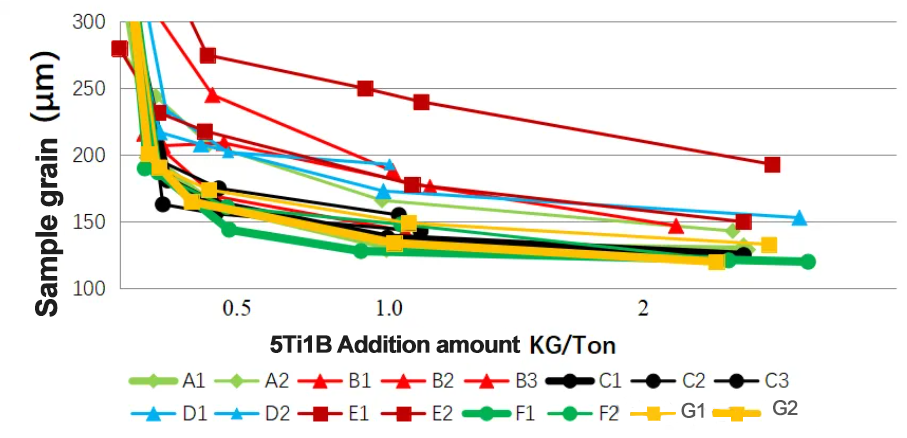

Lokhu kushintsha kwepharadigm kwabeka isisekelo sokusungulwa kwesicwengisisi sokusanhlamvu esiphezulu. Eshintsha ukugxila ku-alloy ye-aluminium kuya kusicwengisisi sokusanhlamvu se-Al-Ti-B ngokwayo, uDkt. Vainik wenze izivivinyo zejika lokuhluzwa okusanhlamvu kumaqoqo angu-16 ahlukene emikhiqizo engu-5Ti1B esebenzisa iphrothokholi yokuhlola emisiwe ye-Opticast. Ngaphansi kokwakheka kwamakhemikhali okufanayo nezimo zokupholisa, inqwaba kuphela eyahluka. Imiphumela ibishaqisa—ngisho namaqoqo avela kumkhiqizi ofanayo kanye nebanga abonise ukuhluka okukhulu kwamandla okucwengisiswa. Idatha idalule iphuzu lobuhlungu bemboni obushaywe indiva isikhathi eside: indlela ye-Tp-1, esetshenziswa kusukela ngo-1987, yehlulekile ukulinganisa umthamo wangempela wokucwenga wemikhiqizo ye-Al-Ti-B.

Ngaso leso sikhathi, i-MQP yathola i-Opticast AB. Umsunguli u-John Courtenay, ebona izidingo eziphuthumayo zemakethe, uhlongoze umbono ophazamisayo: ukuhlanganisa indlela yokuthuthukisa ye-Opticast “nomthamo omkhulu wokucolisiswa” isihlungi sokusanhlamvu. Okuzogxilwa kuzo kuzosuka ekulawuleni amazinga okwengeza kuye ekuthuthukiseni ukusebenza kahle, kubhekwane nomsuka wezinselelo zemboni. Lolu shintsho lwaholela ekuchazweni kabusha kwalokho okwakuhlanganisa “umcwengi wokusanhlamvu osebenza kahle kakhulu.” I-MQP iyiqambe ngokuthi i-Optifine Super Grain Refiner futhi yashicilela incazelo yayo esemthethweni ku-Light Metals Ehlelwe yi-TMS 2008—isicwengisisi sokusanhlamvu esibonakala ngamandla amakhulu kakhulu enucleation.

Unyaka ka-2007 manje usuqashelwa kabanzi njengomsuka wesicwengisisi sokusanhlamvu esiphezulu. Kwaphawula inguquko lapho imboni iqaphela: isihluthulelo sokuhluzwa okusanhlamvu akukona ukuthi “ukwengezwa okungakanani,” kodwa “ukuthi umcwengi unamandla kangakanani.” Ngalokhu kucatshangelwa kabusha—kusuka ekuqwashiseni ngokuhlukahluka kuye encazelweni yomkhiqizo—i-MQP ivule inkathi entsha yokukhiqiza okuseqophelweni eliphezulu ekucutshungulweni kwe-aluminium.

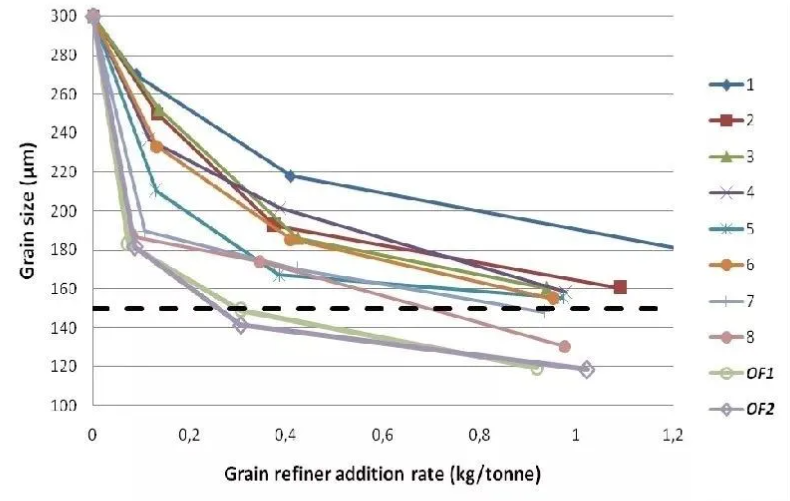

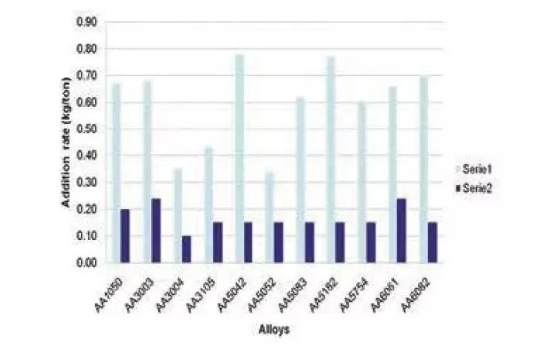

Ijika lekhono lokucwenga okusanhlamvu le-aluminum titanium boron evamile libonisa ukushintshashintsha okumangalisayo kwekhono lokucwenga okusanhlamvu le-aluminium titanium boron.

Amajika ekhono lokucwenga No. 1-8 abonisa umehluko omkhulu ekhonweni lokucwenga lamaqoqo angu-8 emikhiqizo evela kumkhiqizi ofanayo.

I-OF-1 kanye ne-OF-2 amajika ekhono lokucwenga le-Optifine super aluminium titanium boron, abonisa ukuthi umkhiqizo unekhono lokucwenga elisebenzayo nelizinzile.

II. Isisekelo Sesayensi: Umehluko Wezinga Le-Atomic

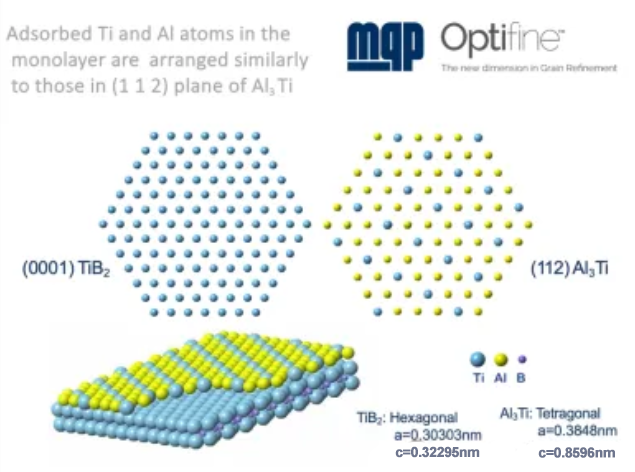

Ukuqamba okusha okuhlala njalo kudinga ukuqonda okujulile kwezimiso zesayensi eziyisisekelo. Ukusebenza okumangalisayo kwe-Optifine super grain refiner ilele ekucaciseni kwayo ileveli ye-athomu yezindlela zenucleation yokusanhlamvu. Ngo-2021, i-MQP kanye neNyuvesi yaseBrunel yaseLondon yenze ngokuhlanganyela iphrojekthi yocwaningo ethi “The Nucleation Mechanism of α-Aluminium on TiB₂ Surfaces,” enikeza ubufakazi obuphelele besayensi bokusebenza okuphezulu kwesicwengisisi sokusanhlamvu okuphezulu.

Lisebenzisa i-high-resolution transmission electron microscopy (HR-TEM), ithimba labacwaningi lenze ukutholwa okudabukisayo esikalini se-athomu: ukuba khona kwezingqimba ze-athomu ze-TiAl₃ ebusweni bezinhlayiyana ze-TiB₂. Lo mehluko we-microstructure wembule imfihlo eyisisekelo ngemuva kokuhlukahluka ekusebenzeni kahle kokucwengwa. Lapho kuqhathaniswa amasampula amabili—elilodwa elisebenza kahle elihlobene lokucwengisiswa kwe-50% kanti elinye ne-123%—kutholwe ukuthi izinhlayiya eziyi-7 kwezingu-8 ze-TiB₂ kusampula elisebenza kahle kakhulu zinesendlalelo esibonakalayo se-2DC Ti₃Al, kuyilapho 1 kuphela kwabayi-6 okwenze lokho kusampula esebenza kahle kakhulu.

Lokhu okutholakele kwachitha inkolelo yemboni yendabuko yokuthi izinhlayiya ze-TiB₂ zizodwa zaziwumgogodla we-nucleation yokusanhlamvu. Esikhundleni salokho, ucwaningo lwe-MQP lwembula ukuthi ikhwalithi nenani lezendlalelo ezihlangene kobuso kwakuyizinqumo zangempela zamathuba e-nucleation. Izihlungi zezinhlamvu ezisezingeni eliphezulu ezisebenza kahle kakhulu zibonisa ukuhleleka nobuqotho obuphakeme kakhulu bezinga le-athomu ezinhlayiyeni zabo ze-TiB₂ uma kuqhathaniswa nemikhiqizo evamile ye-Al-Ti-B. Le nzuzo ye-microstructural ihumusha ngokuqondile ukusebenza kwe-macroscopic—izinhlamvu ezifanayo kanye nezinhlamvu ezicolekile ngaphansi kwezinga elifanayo lokwengeza, okuholela kukhwalithi yomkhiqizo ephezulu.

Ukulinganisa lo mehluko, i-MQP ithuthukise indlela yokuhlola enelungelo lobunikazi Ye-Relative Refinement Efficiency (RRE), evezwe njengephesenti. Ibalwa ngokuqhathanisa inani lezinhlamvu ezakhiwe nge-ppm B ngayinye nge-mm³ yesampula yokuhlola nereferensi evamile. Uma i-RRE idlula ama-85%, umkhiqizo uhlukaniswa njengomkhiqizo we-Optifine super Al-Ti-B. Le bhentshimakhi yobuningi ayihlinzeki nje kuphela ngesisekelo sesayensi sokuhlola ukusebenza kodwa futhi yenza abakhiqizi bakwazi ukwenza izinqumo ezinolwazi ngokusekelwe emandleni okucwenga angempela.

Kusukela ekutholweni kweleveli ye-athomu kuya kumamethrikhi obuningi, i-MQP iye yabeka isisekelo esiqinile sesayensi sesicwengisisi sokusanhlamvu okuphezulu. Ukuthuthukiswa ngakunye ochungechungeni lwe-Optifine kusekelwa izinqubo ze-athomu ezichaziwe esikhundleni sokuqagela okunamandla.

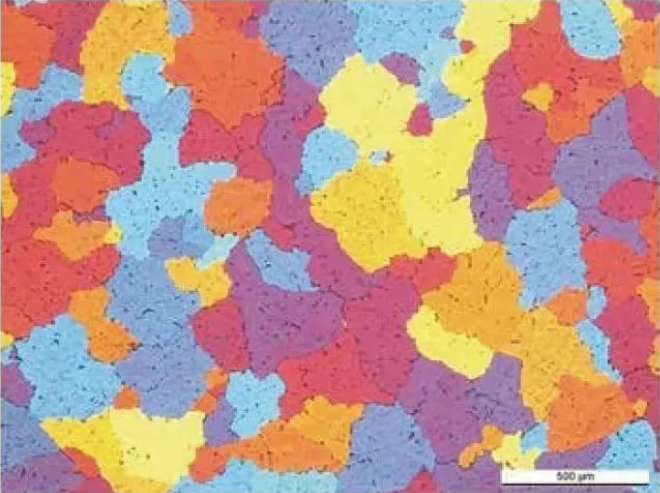

Isakhiwo sengxubevange ye-AA6060 siphathwe nge-Optifine grain refiner. Izinga lokungeza ngu-0.16kg/t, ASTM=2.4

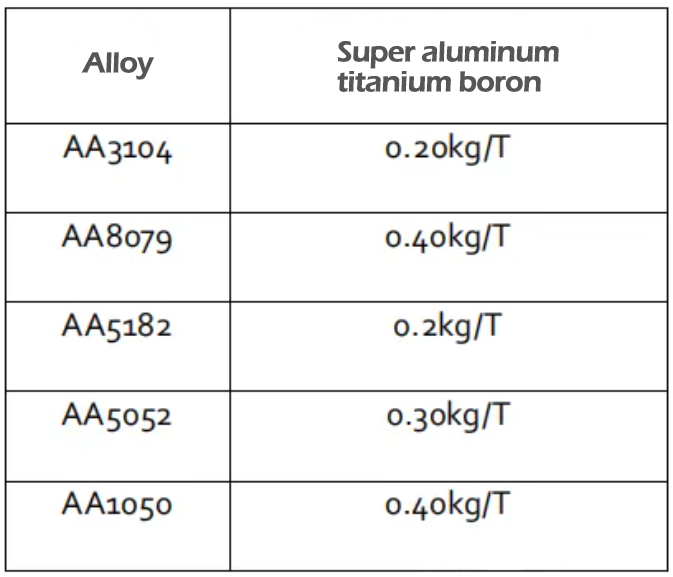

Inani lesihlungi sezinhlamvu ze-Optifine (okuluhlaza okwesibhakabhaka okumnyama) ngokuqhathanisa ne-TiBAI evamile (eluhlaza okwesibhakabhaka okhanyayo) esicwengisisayo esidingekayo ukuze kwenziwe ingxubevange ye-aluminium.

III. Ukuphindaphinda Komkhiqizo: Ukuguqukela Ekusebenzeni Okuphakeme

Ubungqabavu banoma ibuphi ubuchwepheshe bulele ekusunguleni okusha okuqhubekayo. Kusukela ekuqaleni kwayo, i-MQP isebenzise amakhono ayo aqinile e-R&D ukuze ithuthukise ngokuphindaphindiwe umugqa womkhiqizo we-Optifine, iphushe imingcele kukho kokubili ukusebenza kahle nokuzinza. Kusukela ku-Optifine31 100 yasekuqaleni kuya ku-Optifine51 100 futhi manje i-Optifine51 125 esebenza kahle kakhulu, isizukulwane ngasinye sizuze ukwenyuka okuphawulekayo ku-RRE, okuhunyushwa ngokuqondile kumazinga okwengezwa ancishisiwe—okuhlanganisa ifilosofi ye-MQP “yekhwalithi phezu kobuningi.”

Ukukhishwa kokuqala, i-Optifine31 100, ngokushesha kwabonisa amandla ako okuphazamisa. Ngamazinga e-RRE ayidlula kude imikhiqizo yendabuko, igcine ukucolisiswa okusanhlamvu ngenkathi yehlisa amazinga okungezwa ngaphezulu kwama-50% uma kuqhathaniswa nezinkambiso zemboni. Le mpumelelo yaqinisekisa umqondo we-super grain refiner futhi yabeka isisekelo sentuthuko yesikhathi esizayo.

Njengoba izimfuno zezimboni zikhula, i-MQP yethula i-Optifine51 100, eyathuthukisa ukufana kokusatshalaliswa kwezinhlayiyana ze-TiB₂ kuyilapho igcina ukuzinza. Ilethe cishe i-RRE ephakeme ngo-20% kuneyasekuqaleni, ivumela ukwehliswa okwengeziwe okungu-15-20% emazingeni angeziwe—elungele i-aerospace nezinto zokwakha ze-premium lapho ikhwalithi nokungaguquguquki kubalulekile.

Esicongweni sohlelo lwamanje yi-Optifine51 125, ithola i-RRE engu-125%. Lokhu kubangelwa izinga eliphezulu kakhulu lokubunjwa kwesendlalelo esibonakalayo se-2DC Ti₃Al ezinhlayiyeni ze-TiB₂. Idatha yokuhlola iqinisekisa ukuthi amathuba e-nucleation alo mkhiqizo aphakeme izikhathi ezingu-2-3 kunezinye izindlela ezivamile, okugcina ukusebenza okuzinzile ngisho nasezinhlelweni ze-alloy eziyinkimbinkimbi noma ukuncibilika kokuqukethwe okugaywe kabusha. Kubakhiqizi bemikhiqizo ye-aluminium enenani eliphezulu, i-Optifine51 125 yehlisa izindleko zokuhlanza ngamaphesenti angaphezu kuka-70 futhi yehlisa ngokuphawulekayo izinsalela ezibangelwa izinhlamvu ezimahhadla.

Ngo-2025, i-MQP yamemezela uhlelo lwayo lomkhiqizo oluhlanzekile lwe-Optifine502, inweba indlela entsha yokwenza izinto ezintsha. Iqondise ukonakala kwendawo, lokhu okuhlukile kulawula ngokunembile ubuningi bezinhlayiyana ze-TiB₂ ukuze kuncishiswe ukuhlangana kwezinhlayiyana kuyilapho kulondolozwa ukusebenza kahle kokucwengwa. Ilungele ukuhlinzeka ngezinhlelo zokusebenza ezinjengama-foil e-aluminium abushelelezi kanye namaphaneli okuqeda isibuko, ukuxazulula enye futhi inselele yemboni ethathe isikhathi eside ikhona.

Kusukela ekuthuthukiseni ukusebenza kahle kuye ekuthuthukiseni ikhwalithi yendawo ephezulu, ukuvela komkhiqizo we-MQP ngokusobala kulandela umqondo owodwa owumongo: ukusungulwa kwesayensi, okugxile kumakhasimende okulolonga kabusha uchungechunge lwenani eligcwele lokucubungula i-aluminium.

IV. Ukuqinisekiswa Kwembulunga yonke: Kusukela Ekuthathweni Kwangaphambi Kokutholwa Kuya Kuzinga Lemboni

Inani lobuchwepheshe obusha ekugcineni lifakazelwa ngokutholwa okusabalele. Ngo-2008, ngenkathi i-Hulamin yaseNingizimu Afrika iba yinkampani yokuqala ukuvivinya isihlungi sezinhlamvu esikhulu se-Optifine, bambalwa ababelindele ukuthi leso sinqumo sasizobaluleka kangakanani. Iwusebenzisa ekukhiqizweni kwengxubevange ye-AA1050, i-Hulamin yazuza imiphumela emangalisayo—ukunciphisa ukungezwa kwesicwengisisi kusuka ku-0.67 kg/ton kuya ku-0.2 kg/ton, ukonga okungu-70%. Lokhu akwehlisanga izindleko kuphela kodwa kuphinde kwaqinisekisa ukwethembeka komhlaba wangempela womkhiqizo.

Impumelelo ye-Hulamin ivule imakethe yomhlaba wonke ye-Optifine. Abakhiqizi be-aluminium abahamba phambili balandela ngokushesha. I-Sapa (kamuva eyatholwa yi-Hydro) yethula i-Optifine ezitshalweni zayo zonke zase-Europe, yehlisa ukusetshenziswa kwesihlungi ngesilinganiso esingu-65% kuwo wonke ama-alloys amaningi. I-Aleris (manje eyi-Novelis) iyisebenzise ekukhiqizweni kweshidi lezimoto, ithuthukisa izakhiwo zemishini ngenkathi yehlisa ukwenqatshwa kwezitembu. I-Alcoa iyifake ekukhiqizeni i-aluminium yebanga le-aerospace, yazuza ukulawulwa okunembile kokuqamba ngenhlanganisela ye-Optifine ne-Opticast.

Ingena e-China ngo-2018, i-MQP yasheshe yazuza umfutho emkhakheni we-aluminium wezwe osezingeni eliphezulu. Njengomkhiqizi nomthengi omkhulu we-aluminium emhlabeni, i-China idinga ukwehlisa izindleko ngokushesha futhi ikhulise ikhwalithi. Ukwethulwa kwe-Optifine kuhambisane ngokuphelele ne-pivot yezwe ekukhiqizeni okusezingeni eliphezulu.

Isibonelo esisodwa esivelele inkampani yaseShayina ye-aluminium foil ekhiqiza ama-foil anemba okuphezulu, lapho abacwengisisi bendabuko babangele izinkinga ezifana namaphinikhodi nokuphuka kwe-foil ngenxa yokuhlukahluka kwenqwaba. Ngemva kokushintshela ku-Optifine51 100, amazinga okungeza ehle asuka ku-0.5 kg/ton aya ku-0.15 kg/ton, kanti amaphutha emigodini yehle ngo-80%. Inkampani ilinganisela ukonga ngonyaka okungaphezu kwezigidi ezingu-RMB ezingu-20 ngenxa yokuncipha kwezinsalela kanye nezindleko eziphansi zokuhluza.

Emkhakheni wamaphrofayili ezakhiwo, umkhiqizi omkhulu waseShayina wasebenzisa i-Optifine ukuze abhekane nokunamathela okungekuhle kokunamathela okubangelwa izinhlamvu ezimahhadla. Isilinganiso sosayizi wokusanhlamvu sehlisiwe sisuka ku-150 μm saya ngaphansi kuka-50 μm, sakhuphula ukunamathela kokunamathela ngo-30% futhi kwakhuphula isivuno somkhiqizo sisuka ku-85% saya ku-98%. Ngezindleko zokonga u-RMB 120 ngethani, inkampani yonga ngaphezu kuka-RMB 12 wezigidi ngonyaka ngomkhiqizo wamathani angu-100,000.

Lezi zibonelo zezifundo zomhlaba wonke zigcizelela isiphetho esisodwa: Isicwengisisi esikhulu sokusanhlamvu se-MQP singaphezu kokuqanjwa kabusha kwaselabhorethri—kuyisixazululo sezimboni esivuthiwe esifakazelwe kuwo wonke amazwekazi. Kusukela eNingizimu Afrika kuya e-Europe, eNyakatho Melika kuya e-China, uchungechunge lwe-Optifine seluphenduke umgogodla wezikhondlakhondla zemboni ezifana ne-Sapa, i-Novelis, ne-Hydro, okusungula izinga elisha: ukugxila ekusebenzeni kahle kokulungiswa, hhayi nje umthamo.

Kusukela ngo-2024, ngaphezu kwama-aluminium processors angama-200 emhlabeni wonke amukele ubuchwepheshe be-MQP, ngokuhlangene bonga amathani angaphezu kuka-100,000 e-Al-Ti-B futhi banqamula ukukhishwa kwekhabhoni cishe ngamathani angama-500,000. Lezi zibalo azibonisi nje izinzuzo zezomnotho kuphela kodwa futhi negalelo elikhulu ekukhiqizeni okusimeme.

V. Ukubheka Phambili: Kusuka Enguqukweni Yezobuchwepheshe kuye Ekuguquleni Kwesistimu Yendawo

Uma ubuchwepheshe budlula imikhawulo yokusebenza, umthelela wabo uvamise ukudlulela ngalé komkhiqizo ngokwawo—ukulungisa kabusha yonke i-ecosystem yemboni. Ukunyuka kwezihlungi zezinhlamvu ezinkulu ze-MQP kuyisibonelo salo mgomo. Njengoba uchungechunge lwe-Optifine luqhubeka nokushintshashintsha futhi luhlukahluka, umthelela walo wokuguqula uyanda ukusuka ezinqubweni zokukhiqiza ukuya kumasegimenti akhuphukayo naphansi ochungechunge lwenani.

Ngokobuchwepheshe, ubambiswano locwaningo lwe-MQP—njengalolu oluneNyuvesi yaseBrunel—lubeke ibhentshimakhi yokusebenzisana kwemboni nezemfundo. Umsebenzi wabo udale imodeli yomjikelezo ogcwele "yocwaningo oluyisisekelo-ukuthuthukiswa kohlelo lokusebenza-izimboni." Njengoba isayensi yezinto ezibonakalayo kanye nobuchwepheshe bokucabanga kwesikali se-athomu buthuthuka, impumelelo yesikhathi esizayo yokulawula i-nano-interface kanye nobuhlakani bokubikezela ingase ithuthukise ukunemba nokuzivumelanisa nezimo.

Ngokombono wesicelo, abacwengisisi bezinhlamvu ezinkulu bazokhula basebenze izimakethe ze-niche. Umkhiqizo we-Optifine502 Clean ukhomba kuthrendi yokwenza ngokwezifiso—ukuhlanganisa izixazululo zezinhlobo ezithile zomkhiqizo (i-foil, ishidi, ama-extrusions) kanye nezimo zenqubo (ukusakazwa kwe-twin-roll, ukusakazwa kwe-semi-continuous cast). Izicwengisisi zangokwezifiso zizosiza abakhiqizi bandise imbuyiselo yezomnotho futhi bakhuthaze ukuncintisana okuhlukile, okunenani eliphezulu kuwo wonke umkhakha.

Esikhathini lapho ukukhiqiza okuluhlaza kubalulekile emhlabeni wonke, izinzuzo zemvelo zobuchwepheshe be-MQP ziphoqa kakhulu. Ngokunciphisa ukusetshenziswa kwe-Al-Ti-B, izihlungi zezinhlamvu ezinkulu zehlisa ukusetshenziswa kwamandla nokukhishwa komfula. Ngesikhathi esifanayo, ikhwalithi yomkhiqizo ethuthukisiwe isho ukumosha okuncane. Njengoba ukulandelwa kwe-carbon footprint kuya kuvame kakhulu, ukusebenzisa izicwengisisi eziphezulu zokusanhlamvu kungase kube imfuneko yokunikezwa kwezitifiketi nokufinyelela emakethe—okusheshisa uguquko lwemboni yekhabhoni ephansi.

E-China, ubuchwepheshe be-MQP bunikeza ukusekelwa okubalulekile ekuthuthukiseni imboni yasekhaya ye-aluminium. Naphezu kokuba umkhiqizi omkhulu emhlabeni wonke, i-China isenayo indawo yokukhula ezigabeni ezisezingeni eliphezulu njenge-aerospace nezimoto. Ngokuvumelana okuthuthukisiwe nokonga kwezindleko, i-Optifine isiza izinkampani zaseShayina ukuthi zinqobe izithiyo zobuchwepheshe futhi zithuthukise ukuncintisana komhlaba wonke. Ngokulandelayo, ukusebenzisana ne-MQP kungakhuthaza ukuqanjwa kwasendaweni, kukhuthaze umjikelezo omuhle “wokwethulwa—ukumuncwa—ukuvuselela kabusha.”

Isikhathi sokuthumela: Jul-26-2025