1 Uhlolojikelele

Inqubo yokukhiqiza yephrofayili yokufaka i-thermal insulation threading iyinkimbinkimbi, futhi inqubo yokuhlanganisa kanye ne-laminating iphuzile uma kuqhathaniswa. Imikhiqizo eseqediwe engena kule nqubo iqedwa ngokusebenza kanzima kwabasebenzi abaningi abasebenza ngaphambili. Uma udoti usuvela enqubweni yokuhlanganisa eyinhlanganisela, iyokwenza Uma idala ukulahlekelwa okukhulu kwezomnotho, kuyoholela ekulahlekelweni kwemiphumela eminingi yangaphambilini yemisebenzi, okuholela ekumosheni okukhulu.

Ngesikhathi sokukhiqizwa kwamaphrofayili wokufakwa kwe-thermal insulation, amaphrofayili avame ukuchithwa ngenxa yezizathu ezahlukahlukene. Isizathu esiyinhloko se-scrap kule nqubo ukuqhekeka kwezinotshi ze-strip-insulating strip. Kunezizathu eziningi zokuqhekeka kwenotshi ye-strip-insulating strip notch, lapha sigxila kakhulu enqubweni yokuthola izizathu zokukhubazeka okufana nomsila oshwabene kanye ne-stratification okubangelwa inqubo ye-extrusion, okuholela ekuqhekekeni kwamaphrofayili okushisa okushisa kwe-aluminium alloy ngesikhathi sokuthunga nokuqothula, futhi sixazulule le nkinga ngokuthuthukisa isikhunta kanye nezindlela.

2 Izimo zenkinga

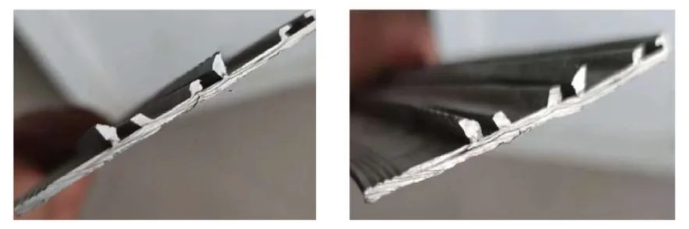

Ngesikhathi senqubo yokukhiqiza eyinhlanganisela yamaphrofayili okufakwa kokushisisa, ukuqhekeka kwenqwaba kwamanotshi avikela ukushisa kuvele kungazelelwe. Ngemva kokuhlola, isenzakalo sokuqhekeka sinephethini ethile. Konke kuqhekeka ekugcineni kwemodeli ethile, futhi ubude bokuqhekeka buyafana. Ingaphakathi kwebanga elithile (20-40cm ukusuka ekugcineni), futhi izobuyela kokujwayelekile ngemva kwesikhathi sokuqhekeka. Izithombe ngemuva kokuqhekeka zikhonjiswe kuMfanekiso 1 nomfanekiso 2.

3 Ukuthola inkinga

1) Okokuqala, hlukanisa amaphrofayili ayinkinga futhi uwagcine ndawonye, hlola ukwenzeka kokuqhekeka ngakunye, futhi uthole ukufana nokuhlukana kokuqhekeka. Ngemuva kokulandelela okuphindaphindiwe, isenzakalo sokuqhekeka sinephethini ethile. Konke kuqhekeka ekugcineni kwemodeli eyodwa. Ukuma kwemodeli ephukile kuyisiqephu esivamile sezinto ezingenayo i-cavity, futhi ubude bokuqhekeka bungaphakathi kwebanga elithile. Ngaphakathi (20-40cm ukusuka ekugcineni), izobuyela kokujwayelekile ngemva kokuqhekeka isikhashana.

2) Kusuka ekhadini lokulandelela ukukhiqizwa kwaleli qoqo lamaphrofayili, singathola inombolo yesikhunta esetshenziswe ekukhiqizeni lolu hlobo, ngesikhathi sokukhiqiza, usayizi wejometri wenotshi yale modeli uyahlolwa, nosayizi wejometri womugqa wokufaka ukushisa, izakhiwo zemishini yephrofayili nobulukhuni bobuso konke kungaphakathi kwebanga elifanele.

3) Ngesikhathi senqubo yokukhiqiza eyinhlanganisela, imingcele yenqubo eyinhlanganisela nemisebenzi yokukhiqiza yalandelwa. Kwakungekho okungavamile, kodwa kwakusekhona imifantu lapho iqoqo lamaphrofayili likhiqizwa.

I-4) Ngemva kokuhlola ukuphuka ekuqhekekeni, ezinye izakhiwo ezingapheli zitholwe. Uma kucatshangelwa ukuthi imbangela yalesi simo kufanele ibangelwe ukukhubazeka kwe-extrusion okubangelwa inqubo ye-extrusion.

I-5) Kusukela kulokhu okungenhla, kungabonakala ukuthi imbangela yokuqhekeka akuyona ubunzima bephrofayili kanye nenqubo ehlanganisiwe, kodwa ekuqaleni kunqunywa ukuthi kubangelwa ukukhubazeka kwe-extrusion. Ukuze kuqhutshekwe nokuqinisekisa imbangela yenkinga, kwenziwa lezi zivivinyo ezilandelayo.

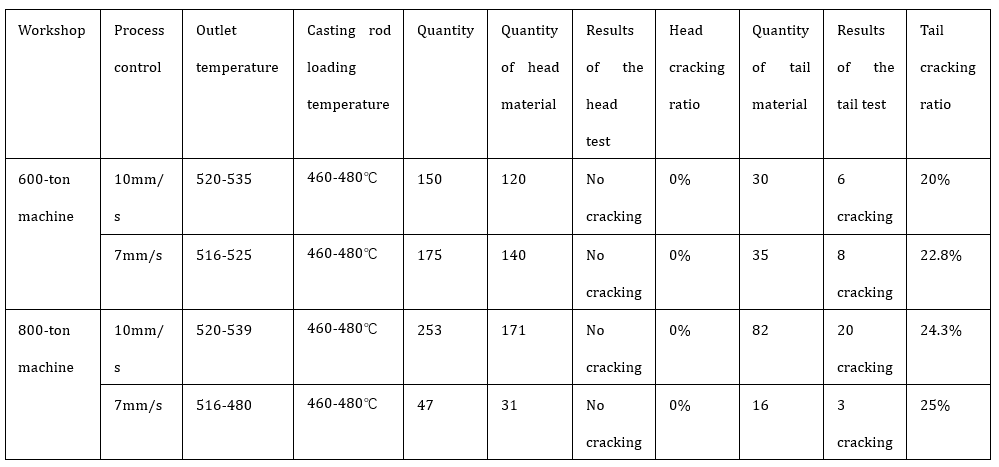

I-6) Sebenzisa isethi efanayo yesikhunta ukwenza izivivinyo emishinini ehlukene yamathoni anezivinini ezihlukene ze-extrusion. Sebenzisa umshini wamathani angama-600 kanye nomshini wamathani angama-800 ukwenza ukuhlolwa ngokulandelana. Maka inhloko yempahla nomsila wempahla ngokwehlukana bese ukupakisha kubhasikidi. Ubulukhuni ngemva kokuguga ku-10-12HW. Indlela yokugqwala kwamanzi ane-alkaline yasetshenziswa ukuhlola iphrofayela ekhanda nasemsila wento. Kutholwe ukuthi umsila wezinto ezibonakalayo unomsila oshwabene kanye ne-stratification phenomena. Isizathu sokuqhekeka kutholwe ukuthi kudalwe wukushwabana komsila kanye ne-stratification. Izithombe ezingemuva kokufakwa kwe-alkali zikhonjiswe kuMfanekiso 2 no-3. Ukuhlolwa okuyinhlanganisela kwenziwe kuleli qoqo lamaphrofayili ukuze kuhlolwe ukwenzeka kokuqhekeka. Idatha yokuhlola ikhonjiswe kuThebula 1.

Izibalo 2 no-3

I-7) Kusukela kudatha esethebula elingenhla, kungabonakala ukuthi akukho ukuqhekeka ekhanda lezinto ezibonakalayo, futhi ingxenye yokuqhekeka emsila wezinto ezibonakalayo inkulu kakhulu. Isizathu sokuqhekeka asihlangene nobukhulu bomshini kanye nesivinini somshini. Isilinganiso sokuqhekeka sezinto zomsila sikhulu kunazo zonke, esihlobene ngokuqondile nobude be-sawing yezinto zomsila. Ngemuva kokuthi ingxenye yokuqhekeka ifakwe emanzini ane-alkaline futhi ihlolwe, umsila we-shrink kanye ne-stratification izovela. Uma umsila oshwabene kanye nezingxenye ze-stratification zinqanyuliwe, ngeke kube nokuqhekeka.

4 Izindlela zokuxazulula izinkinga nezindlela zokuvimbela

I-1) Ukuze unciphise ukuqhekeka kwe-notch okubangelwa yilesi sizathu, ukuthuthukisa isivuno, nokunciphisa imfucuza, izinyathelo ezilandelayo zithathwa zokulawula ukukhiqiza. Lesi sixazululo sifanelekile kwamanye amamodeli afana nalesi modeli lapho ukufa kwe-extrusion kuyifa eliyisicaba. I-shrink tail kanye ne-stratification phenomena ekhiqizwa ngesikhathi sokukhiqizwa kwe-extrusion izodala izinkinga zekhwalithi ezifana nokuqhekeka kwamanotshi okuphela ngesikhathi sokuhlanganisa.

2) Lapho wamukela isikhunta, lawula ngokuqinile usayizi wenothi; sebenzisa ucezu olulodwa lwempahla ukwenza isikhunta esibalulekile, engeza amagumbi okushisela kabili esikhunjeni, noma uvule isikhunta esihlukanisayo esingamanga ukuze unciphise umthelela wekhwalithi womsila oshwabene kanye ne-stratification kumkhiqizo ophelile.

I-3) Ngesikhathi sokukhiqizwa kwe-extrusion, ingaphezulu lenduku ye-aluminium kufanele ihlanzeke futhi ingabi nothuli, amafutha nokunye ukungcola. Inqubo ye-extrusion kufanele isebenzise imodi ye-extrusion encishisiwe kancane kancane. Lokhu kunganciphisa isivinini sokukhipha ekugcineni kwe-extrusion futhi kunciphise umsila oshwabene kanye nokuhlukaniswa.

I-4) Izinga lokushisa eliphansi kanye ne-high speed extrusion kusetshenziswa ngesikhathi sokukhiqizwa kwe-extrusion, futhi izinga lokushisa lenduku ye-aluminium emshinini lilawulwa phakathi kuka-460-480 ℃. Izinga lokushisa lesikhunta lilawulwa ku-470 ℃ ± 10 ℃, izinga lokushisa lomgqomo we-extrusion lilawulwa cishe ku-420 ℃, futhi izinga lokushisa lokukhipha i-extrusion lilawulwa phakathi kuka-490-525 ℃. Ngemuva kwe-extrusion, ifeni ivuliwe ukuze iphole. Ubude obusele kufanele bunyuswe ngaphezu kuka-5mm kunokuvamile.

I-5) Lapho ukhiqiza lolu hlobo lwephrofayili, kungcono ukusebenzisa umshini omkhulu ukwandisa amandla okukhipha, ukuthuthukisa izinga lokuhlanganisa insimbi, nokuqinisekisa ukuminyana kwezinto.

I-6) Ngesikhathi sokukhiqizwa kwe-extrusion, ibhakede lamanzi e-alkali kufanele lilungiswe kusengaphambili. Umsebenzisi uzosusa umsila wento ukuze ahlole ubude bomsila oshwabene kanye nokuhlelwa. Imigqa emnyama endaweni enamathiselwe i-alkali ibonisa ukuthi umsila oshwabene kanye nokuhlukaniswa kwenzekile. Ngemva kokusaha okwengeziwe, Kuze kube yilapho ingxenye ephambanayo ikhanya futhi ingenayo imigqa emnyama, hlola izinti ze-aluminium ezingu-3-5 ukuze ubone ubude buyashintsha ngemva kokushwabana komsila kanye nokuhlukaniswa. Ukuze ugweme ukuncipha komsila kanye ne-stratification ukuthi ingalethwa emikhiqizweni yephrofayili, i-20cm yengezwa ngokuya ende kunazo zonke, inqume ubude bomsila wesethi yesikhunta, isuse ingxenye eyinkinga bese uqala ukusika umkhiqizo oqediwe. Ngesikhathi sokusebenza, inhloko nomsila wempahla inganyakaziswa futhi isawe ngokuguquguquka, kodwa amaphutha akufanele alethwe kumkhiqizo wephrofayili. Igadwa futhi ihlolwe ngokuhlolwa kwekhwalithi yomshini. Uma ubude bomsila oshwabene kanye ne-stratification kuphazamisa isivuno, susa isikhunta ngesikhathi futhi usike isikhunta kuze kube yinto evamile ngaphambi kokuba ukukhiqizwa okuvamile kuqale.

5 Isifinyezo

1) Amaqoqo amaningana amaphrofayili emigqa evikela ukushisa akhiqizwe kusetshenziswa izindlela ezingenhla ahloliwe futhi akukho ukuqhekeka kwenotshi okufanayo okwenzeka. Amanani wesici se-shear wamaphrofayili wonke afinyelele izidingo ezijwayelekile ze-GB/T5237.6-2017 ezijwayelekile "Amaphrofayili Okwakha I-Aluminium Alloy No. 6 Ingxenye: Yamaphrofayili Okuvikela".

2) Ukuze kuvinjwe ukwenzeka kwale nkinga, kuye kwasungulwa uhlelo lokuhlola nsuku zonke ukuze kubhekwane nenkinga ngesikhathi futhi kwenziwe izilungiso ukuze kuvinjwe amaphrofayili ayingozi ukuthi agelezele enqubweni eyinhlanganisela futhi anciphise imfucuza ohlelweni lokukhiqiza.

I-3) Ngaphezu kokugwema ukuqhekeka okubangelwa ukukhubazeka kwe-extrusion, umsila we-shrink kanye ne-stratification, kufanele sihlale sinake isenzakalo sokuqhekeka esibangelwa izici ezifana ne-geometry ye-notch, ukuqina kobuso kanye nezakhiwo zemishini yezinto ezibonakalayo kanye nemingcele yenqubo yenqubo eyinhlanganisela.

Ihlelwe nguMay Jiang evela kwaMAT Aluminium

Isikhathi sokuthumela: Jun-22-2024