1. Ukuqinisekiswa kwesimiso somzimba sefomula ewumongo

Umthetho Wokongiwa KweMisa

Wonke amafomula asekelwe esimweni somzimba se-m=ρ×V (ubuningi = ukuminyana × ivolumu)

Inani lokuminyana

Ukuminyana kwethiyori ye-aluminium emsulwa: 2,698 kg/m³ (20℃)

Inani elilinganiselwe lika-2,700 kg/m³ linengqondo ekubalweni kwezimboni (iphutha <0.1%)

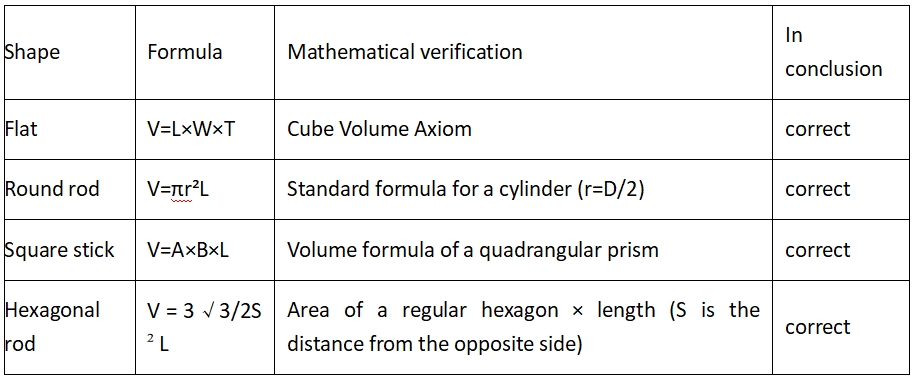

2. Ukuqinisekiswa Kokuqina Kwamafomula EJiyomethri

2.1. Ifomula yevolumu yejometri ejwayelekile

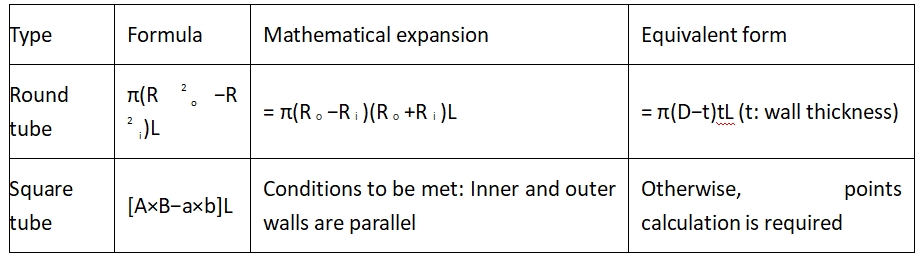

Imikhawulo yefomula yeshubhu yesikwele:

Lokhu kuyiqiniso uma ukushuba kodonga lweshubhu kufana futhi i-engeli yangaphakathi iyi-engeli elungile (ishubhu lesikwele langempela linoguquko oluyindilinga, futhi iphutha lethiyori licishe libe ngu-1-3%).

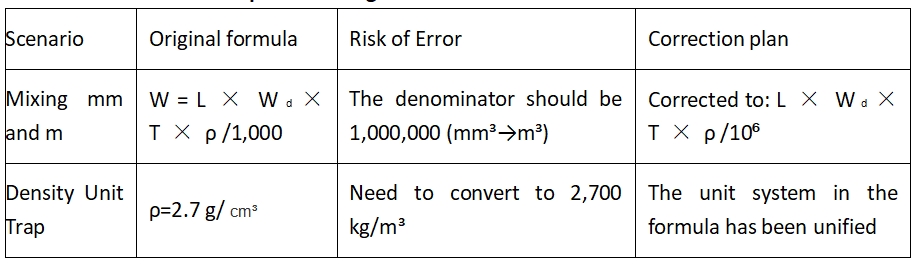

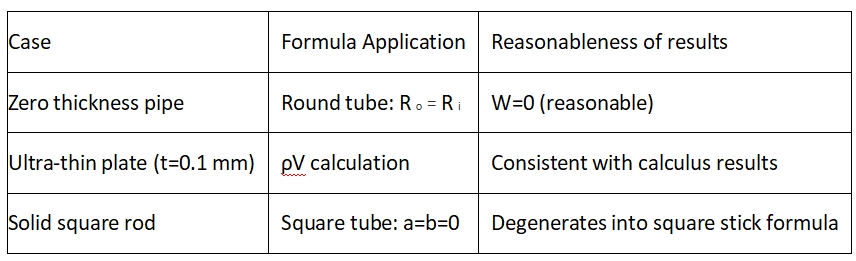

3. Ukuqinisekisa Ukungaguquguquki Kwesistimu

Uphenyo lwephuzu lokubeka engcupheni lokubalwa kweyunithi

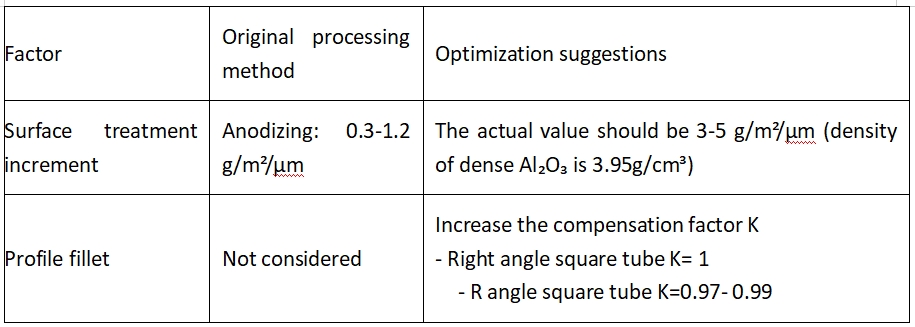

4. Isichibiyelo Sokufaneleka Kobunjiniyela

4.1. Isinxephezelo sezinto ezingafanelekile

4.2. Ukulinganisa umthelela wokubekezelelana

Ukubekezelela ukuqina ±10% → Ukuchezuka kwesisindo ±(8% ~ 12%) (izingxenye ezinezindonga ezincane zizwela kakhulu)

Isixazululo: W okwangempela = W ithiyori × (1 + Δt / t) ( Δt : ukuchezuka kobukhulu)

5. Ukuhlolwa Kwesimo Somngcele

Ukuqinisekiswa kwezimo ezimbi kakhulu:

Isimo esididayo sokuminyana

I-7xxx alloy (7075): Ukuminyana okukaliwe 2.810 g/cm³ → Uma u-2.7g/cm³ esetshenziswa ngephutha, iphutha lingu-+4.1%.

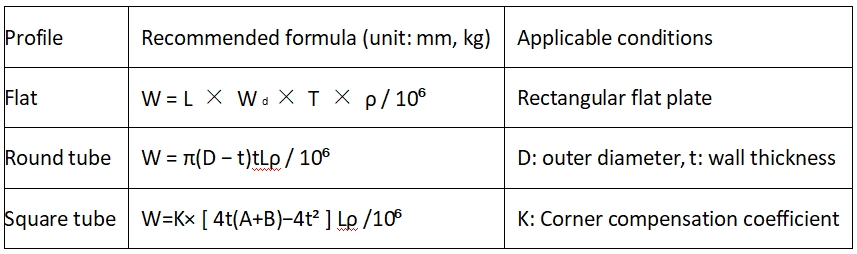

Ithebula lefomula

4t(A + B)- 4t² isibalo sobunjiniyela esijwayelekile esibalwa ngokuphindaphinda umjikelezo wesigaba ngogqinsi lwebonda bese udonsa amakhona amane.

Isibonelo sokubala:

Ipuleti le-aluminium engu-1.6061(1000 × 500 × 10 mm, ubude 2 m): W = 1000 × 500 × 2 × 0.0027 = 27 kg

2.7075 ithubhu eliyindilinga(ububanzi obungaphandle 50 mm, ukujiya kodonga 3 mm, ubude 1.5 m): W = [(50-3)×3×3.1416×1.5]×0.00283 ≈ 5.65 kg

3. Ithubhu yesikwele(40×40×2mm, ubude 3m): W = [2×2×(40+40-4)×3]×0.0027×0.98 ≈ 2.42 kg

Ukuhamba komsebenzi Okunconyiwe

1. Khetha ukuminyana → 2. Kala usayizi wangempela → 3. Khetha isici sesinxephezelo → 4. Bala ngefomula

Isikhathi sokuthumela: Jun-17-2025