Inqubo yokukhiqiza amasondo emoto ye-aluminium alloy ihlukaniswe ikakhulukazi izigaba ezilandelayo:

1. Inqubo yokusakaza:

• I-Gravity casting: Thela ingxube ye-aluminium ewuketshezi esibunjeni, gcwalisa isikhunta ngaphansi kwamandla adonsela phansi bese uyipholisa ibe yisimo. Le nqubo inokutshalwa kwezimali kwemishini ephansi kanye nokusebenza okulula, okulungele ukukhiqizwa okuncane. Kodwa-ke, ukusebenza kahle kokulingisa kuphansi, ukungaguquguquki kwekhwalithi yomkhiqizo kubi, futhi izici zokuphonsa ezifana nezimbotshana nokuncipha zivame ukwenzeka.

• Ukusakaza kwengcindezi ephansi: Ku-crucible evalekile, uketshezi lwe-aluminium alloy lucindezelwa esikhunjeni ngengcindezi ephansi ngegesi engasebenzi ukuze luqiniswe ngaphansi kwengcindezi. Ama-castings akhiqizwa yile nqubo anesakhiwo esiminyene, ikhwalithi enhle yangaphakathi, ukusebenza kahle kokukhiqiza okuphezulu, futhi kufanelekile ukukhiqizwa ngobuningi, kodwa ukutshalwa kwezimali kwemishini kukhulu, izidingo zesikhunta ziphezulu, futhi izindleko zesikhunta nazo ziphezulu.

• Ukusakazwa kwe-spin: Kuyinqubo ethuthukisiwe esekelwe ekusakazeni kwengcindezi ephansi. Okokuqala, indawo engenalutho yesondo yenziwa ngokusakazwa kwengcindezi ephansi, bese kuthi okungenalutho kugxilwe emshinini wokuphotha. Isakhiwo sengxenye yerimu siyakhubazeka kancane kancane futhi sinwetshwe yisikhunta esijikelezayo nokucindezela. Le nqubo ayigcini nje kuphela izinzuzo zokusakaza okuphansi kwengcindezi, kodwa futhi ithuthukisa amandla nokunemba kwesondo, kuyilapho inciphisa isisindo sesondo.

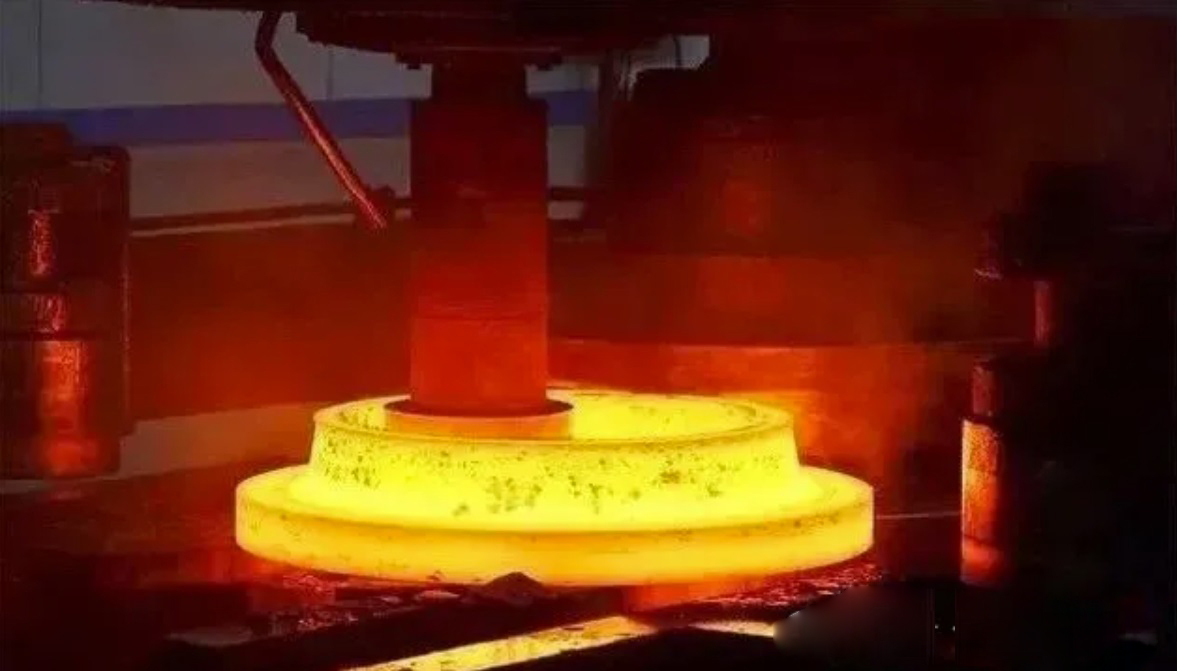

2. Inqubo yokuqamba

Ngemva kokuba ingxubevange ye-aluminium ishiselwe ezingeni lokushisa elithile, ihlanganiswa ibe isikhunta ngomshini wokubumba. Izinqubo zokuqamba zingahlukaniswa ngezinhlobo ezimbili ezilandelayo:

• Ukufoja okujwayelekile: Lonke ucezu lwe-aluminum ingot lufojwa ngokuqondile lube sesimweni sesondo ngaphansi kwengcindezi ephezulu. Isondo elikhiqizwe yile nqubo linokusetshenziswa okuphezulu kwezinto ezibonakalayo, ukumosha okuncane, izici ezinhle kakhulu zemishini ye-forging, namandla amahle kanye nokuqina. Kodwa-ke, ukutshalwa kwezimali kwemishini kukhulu, inqubo iyinkimbinkimbi, futhi izinga lobuchwepheshe lomsebenzisi liyadingeka ukuthi libe phezulu.

• I-semi-solid forging: Okokuqala, ingxubevange ye-aluminiyamu ifudunyezwa ibe semi-solid, ngaleso sikhathi ingxubevange ye-aluminium inoketshezi oluthile kanye nokuqina, bese ifojiwe. Le nqubo inganciphisa ukusetshenziswa kwamandla enqubweni yokubumba, ithuthukise ukusebenza kahle kokukhiqiza, futhi ithuthukise ikhwalithi yesondo.

3. Inqubo yokushisela

Ishidi ligoqwa libe isilinda futhi lishiselwe, futhi limane licutshungulwe noma licindezelwe libe yirimu lamasondo elinesikhunta, bese kuthi i-pre-cast wheel disc ishiselwe ukukhiqiza isondo. Indlela ye-welding ingaba i-laser welding, i-electron beam welding, njll. Le nqubo idinga umugqa wokukhiqiza ozinikele onekhwalithi ephezulu yokukhiqiza futhi ifanele ukukhiqizwa okukhulu, kodwa ukubukeka kumpofu futhi izinkinga zekhwalithi zokushisela zivame ukwenzeka ezindaweni zokushisela.

Isikhathi sokuthumela: Nov-27-2024