Ukufakwa kwe-aluminium kuyindlela yokukhiqiza ukubekezelela okuphezulu kanye nezingxenye zekhwalithi ephezulu ngokuthela i-aluminium encibilikisiwe endaweni eklanywe ngokunembile nangokunemba eyenziwe ngobunjiniyela, isikhunta, noma ifomu. Kuyinqubo ephumelelayo yokukhiqizwa kwezingxenye eziyinkimbinkimbi, eziyinkimbinkimbi, ezinemininingwane ehambisana ncamashi nokucaciswa komklamo wokuqala.

Inqubo Yokusakaza Ye-Aluminium

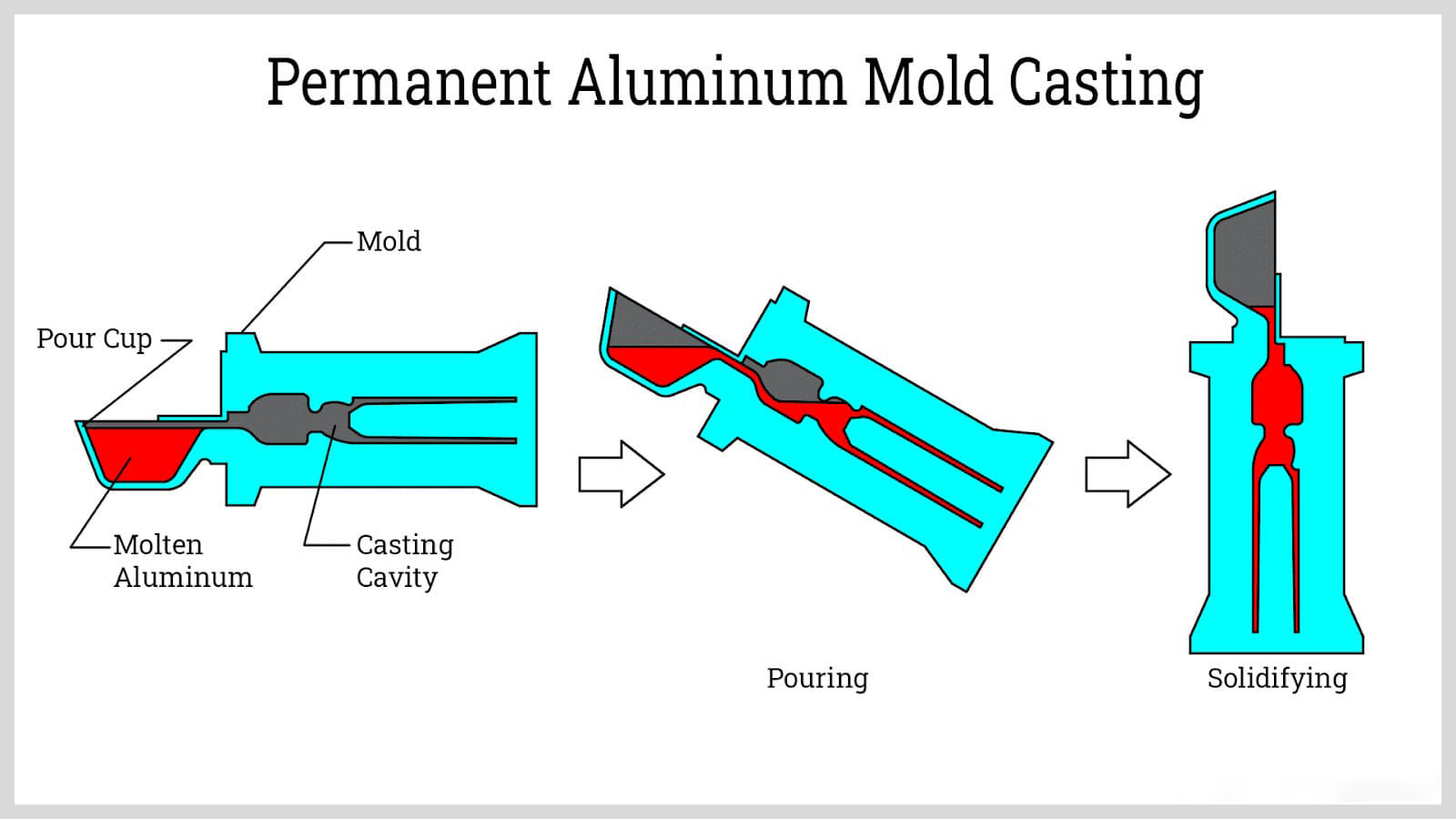

1.Permanent Mold Casting

Izindleko eziningi zokubunjwa kwesikhunta se-aluminium unomphela umshini nokubumba isikhunta, esivame ukwenziwa ngensimbi empunga noma ngensimbi. Isikhunta sibunjwa sibe yisimo sejiyomethri sengxenye eklanyelwe ngokucaciswa nokuma kwengxenye ehlukaniswe ngamahafu amabili. Enqubweni yomjovo, ama-halves esikhunta avaliwe ngokuqinile ukuze kungabikho moya noma ukungcola okukhona. Isikhunta siyashiswa ngaphambi kokuthelwa kwe-aluminium encibilikisiwe, ekwazi ukulayishwa, ithululwe, noma ijovwe.

Ekupheleni kwenqubo, isikhunta sivunyelwe ukupholisa ukuze ingxenye ye-aluminium iqine. Uma selipholile, ingxenye isuswa ngokushesha esikhunjeni ukuvimbela ukwakheka kweziphambeko.

Kungakhathaliseki ukuthi le nqubo ingase ibonakale ilula kangakanani, iyindlela esungulwe ngokwesayensi nangobuchwepheshe yokukhiqiza izingxenye zevolumu ephezulu.

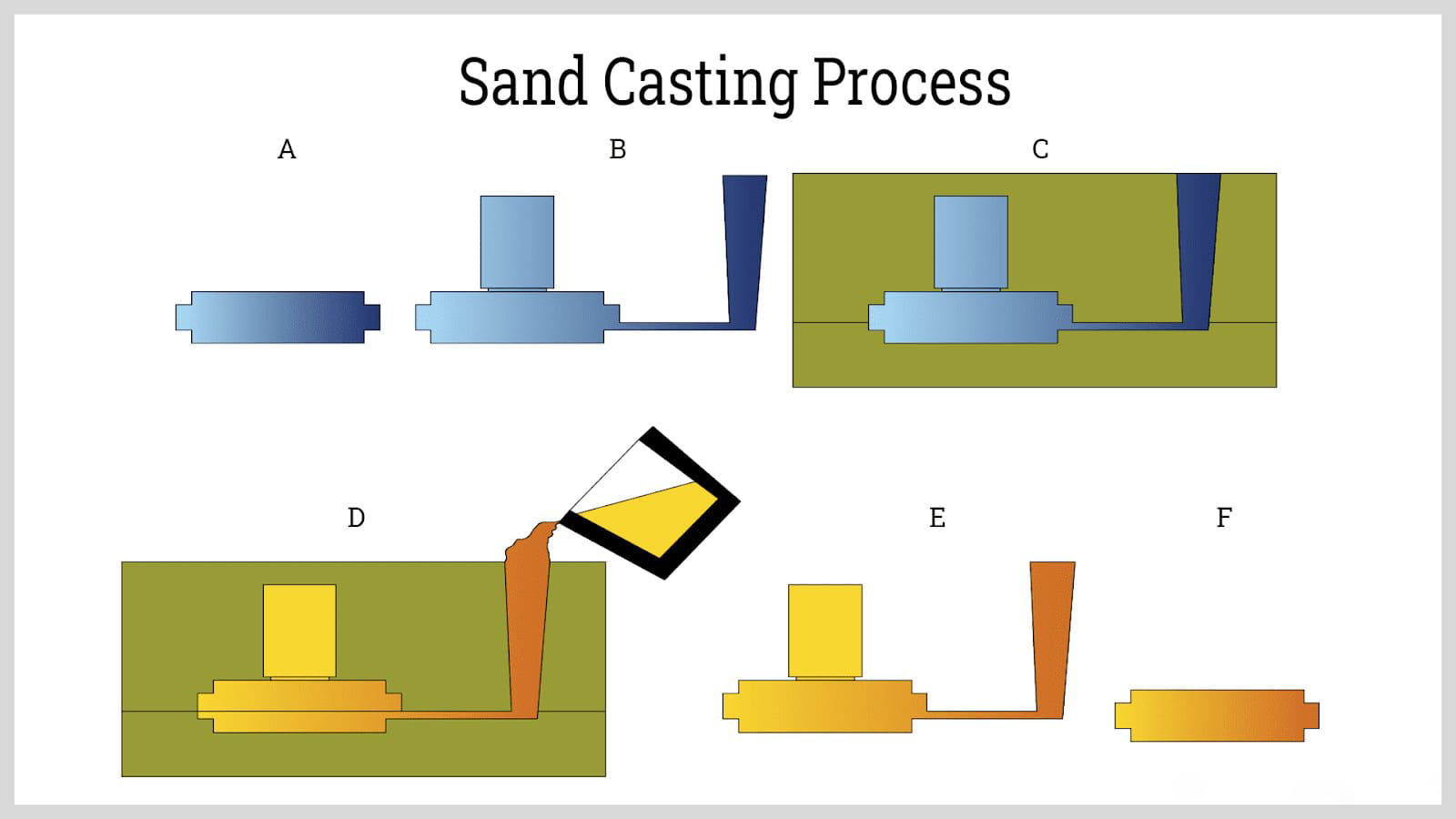

2.Ukulingisa kwesihlabathi

Inqubo yokuphonsa isihlabathi ihlanganisa ukupakisha isihlabathi eduze kwephethini engasetshenziswa kabusha enomumo, imininingwane, nokucushwa komkhiqizo wokugcina. Kufakwe kuphethini izikhuphukeli ezivumela insimbi encibilikisiwe ukuthi ithelwe esibunjeni kanye ne-aluminiyamu eshisayo yondle ukubunjwa ngesikhathi sokuqiniswa ukuvimbela ukushwabana kwe-porosity.

Kufakwe iphethini i-sprue evumela insimbi encibilikisiwe ukuba ifakwe esikhunjini. Ubukhulu bephethini bukhulu kancane kunomkhiqizo ukuze kubangele ukuncipha ngesikhathi senqubo yokupholisa. Isihlabathi sinesisindo namandla okugcina ukwakheka kwephethini futhi amelana nokuxhumana nensimbi encibilikisiwe.

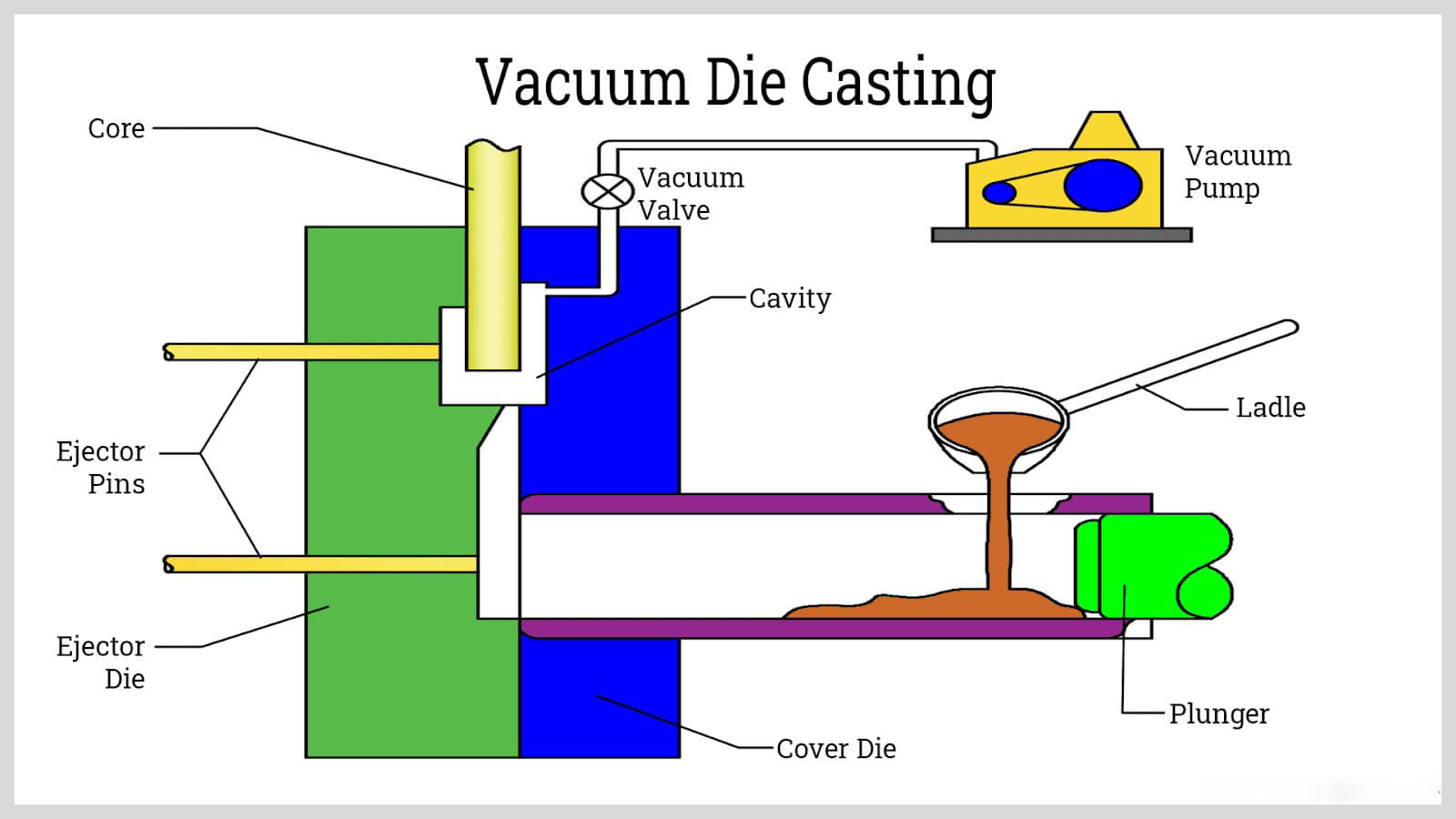

4.Vacuum Die Casting

4.Vacuum Die Casting I-vacuum die casting isebenzisa insimbi engangenisi umoya enendawo yokuvula i-sprue ngezansi kanye ne-vacuum ephumayo phezulu. Inqubo iqala ngokucwilisa i-sprue ngaphansi kobuso be-aluminium encibilikisiwe. Ivacuum iyakhiwa kumamukeli okudala umehluko wengcindezi phakathi komgodi wokufa kanye ne-aluminium encibilikisiwe ku-crucible.

Umehluko wengcindezi udala ukuthi i-aluminium encibilikisiwe igeleze ikhuphuke i-sprue ingene endaweni eyi-die, lapho i-aluminium encibilikisiwe iqina. Ifa liyasuswa kumamukeli, livulwe, bese ingxenye iyakhishwa.

Ukulawula i-vacuum kanye nomehluko wengcindezi phakathi kwe-die cavity ne-aluminium encibilikisiwe kwenza kube nokwenzeka ukulawula izinga lokugcwalisa elidingwa ingxenye yedizayini kanye nezidingo zesango. Ukulawulwa kwezinga lokugcwalisa kuthuthukisa ikhono lokunquma umsindo wengxenye eqediwe.

Ukucwiliswa kwe-sprue ngaphansi kobuso be-aluminium encibilikisiwe kuqinisekisa ukuthi i-aluminium encibilikisiwe izoba ingxubevange emsulwa engenawo ama-oxide nenzila. Izingxenye zihlanzekile futhi zizwakala zinempahla encane yangaphandle.

5.Ukutshala imali

Ukufakwa kwe-investimenti, okubuye kwaziwe ngokuthi i-wax casting elahlekile, iqala ngokuthi i-wax ijovwe efashini ukuze kwakhiwe iphethini yomkhiqizo oqediwe. Amaphethini ane-wax anamathiselwe ku-sprue ukwenza ukucushwa kwe-ike yesihlahla. Isihlahla sicwiliswa odaka izikhathi eziningi, okwenza igobolondo le-ceramic eliqinile lizungeze umumo we-wax.

Uma i-ceramic isimisiwe futhi yaqina, ishiswa ku-autoclave ukuze kuqedelwe ukutubeka kwe-dewax. Ukuze kuzuzwe izinga lokushisa elifiselekayo legobolondo, lishiswa ngaphambili ngaphambi kokuba ligcwaliswe nge-aluminium encibilikisiwe, ethelwa ku-sprue futhi idlule uchungechunge lwabagijimi namasango esikhunjeni. Lapho izingxenye ziba lukhuni, i-ceramic iyasuswa kusale izingxenye ezixhunyiwe zesihlahla ukuze zisikwe esihlahleni.

6.I-Foam Elahlekile Yokusakaza

Inqubo yokukhipha igwebu elahlekile ingolunye uhlobo lokutshala imali lapho i-wax ithathelwa indawo ngegwebu le-polystyrene. Iphethini ibunjwe kusukela ku-polystyrene ekuhlanganiseni kweqoqo elifana nomgijimi kanye nezihlahla zokutshala imali. Ubuhlalu be-polystyrene bujovwa ekubunjweni kwe-aluminiyamu eshisayo ngengcindezi ephansi enesitimu esingeziwe ukuze kunwetshwe i-polystyrene ukuze igcwalise izimbotshana.

Iphethini ibekwe esihlabathini esomile esiminyene esinyakaziswayo ukuze kuqedwe ama-voids noma amaphakethe omoya. Njengoba i-aluminium encibilikisiwe ithululelwa esikhunjini sesihlabathi, igwebu liyashiswa, bese kwakheka ukubunjwa.

Izicelo Ezivamile Ze-Casting Aluminium

Ngenxa yezakhiwo zayo ezinhle kakhulu zomzimba namakhemikhali, izimboni eziningi ezinkulu zisebenzisa i-cast aluminium. Nazi izinto ezimbalwa ezivamile ezisetshenziswayo.

1. Imboni Yezokwelapha

Abakhiqizi bezingxenye zezokwelapha bathembele ku-aluminium cast ukuze baqine futhi bangasindi ekwenzeni ama-prosthetics, amathreyi okuhlinza, njll. Ngaphandle kwalokho, le nqubo ifanele ukwenza izimo eziyinkimbinkimbi nezinembile imboni eyaziwa ngayo. Futhi, i-aluminium iyimpahla efanele ngenxa yokumelana nokugqwala njengoba imishini eminingi yezokwelapha ihlangana noketshezi lomzimba.

2. Imboni yezimoto

Abakhiqizi bezingxenye zezimoto bathembele kumasanti e-aluminium ukuze bathole izakhiwo zabo ezingasindi ngaphandle kokuhlanganisa amandla nokuqina. Ngenxa yalokho, iye yathuthukisa ukusebenza kahle kukaphethiloli. Ngaphezu kwalokho, ukwenza izingxenye zezimoto ezinobumo obuyinkimbinkimbi ngenqubo yokukhipha i-aluminium kulula. Izinsimbi ze-aluminium zilungele ukwenza izingxenye ezifana namabhuleki namasondo okuqondisa.

3. Culinary Industry

I-Cast aluminium iwusizo embonini yezokupheka ngenxa yokuqina kwayo, ukumelana nokugqwala, engasindi, kanye ne-heat conduction enhle kakhulu. Ngaphandle kwalokho, impahla ifanele ukwenza i-cookware ngenxa yokushisa kwayo okuhle kakhulu, okungukuthi, ingashisa futhi iphole ngokushesha.

4. Imboni Yezindiza

Izingxenye ze-Aluminium zifanelekile embonini yezindiza ngenxa yokukhanya kwazo namandla. Isisindo sayo esincane sivumela indiza ukuthi isebenzise uphethiloli omncane ukuze ithwale isisindo esiningi.

Umthombo:

https://www.iqsdirectory.com/articles/die-casting/aluminum-casting.html

https://waykenrm.com/blogs/cast-aluminum/#Common-Applications-of-Casting-Aluminium

Ihlelwe nguMay Jiang evela kwaMAT Aluminium

Isikhathi sokuthumela: Jul-26-2023