Isizathu esenza ukuthi amaphrofayili e-aluminium alloy asetshenziswe kakhulu empilweni nasekukhiqizeni ukuthi wonke umuntu uzibona ngokugcwele izinzuzo zawo ezifana nokuminyana okuphansi, ukumelana nokugqwala, ukuhanjiswa kukagesi okuhle kakhulu, izakhiwo ezingezona i-ferromagnetic, ukwakheka, nokusebenziseka kabusha.

Imboni yephrofayili ye-aluminium yaseShayina ikhule isuka ekuqaleni, isuka kwencane iye enkulu, yaze yathuthuka yaba izwe elikhulu lokukhiqiza iphrofayili ye-aluminium, elinomkhiqizo osezingeni lokuqala emhlabeni. Kodwa-ke, njengoba izidingo zemakethe zemikhiqizo yephrofayili ye-aluminium ziqhubeka nokwanda, ukukhiqizwa kwamaphrofayili e-aluminium kuye kwathuthukiswa ngendlela eyinkimbinkimbi, ukunemba okuphezulu, nokukhiqiza okukhulu, okulethe uchungechunge lwezinkinga zokukhiqiza.

Amaphrofayili e-aluminium akhiqizwa kakhulu yi-extrusion. Ngesikhathi sokukhiqiza, ngaphezu kokucabangela ukusebenza kwe-extruder, ukuklama kwesikhunta, ukwakheka kwenduku ye-aluminium, ukwelashwa kokushisa nezinye izici zenqubo, umklamo we-cross-sectional wephrofayili kufanele ucatshangelwe. Idizayini engcono kakhulu ye-cross-section yephrofayili ayikwazi nje ukunciphisa ubunzima benqubo kusuka emthonjeni, kodwa futhi ithuthukise ikhwalithi nokusetshenziswa komphumela womkhiqizo, yehlise izindleko futhi ifinyeze isikhathi sokulethwa.

Lesi sihloko sifingqa amasu amaningana avame ukusetshenziswa ekwakhiweni kwengxenye yephrofayili ye-aluminium ngokusebenzisa izimo zangempela ekukhiqizeni.

1. Izimiso zesigaba sephrofayela ye-aluminium

I-Aluminium profile extrusion iyindlela yokucubungula lapho induku ye-aluminium evuthayo ilayishwa emgqonyeni we-extrusion, futhi ingcindezi isetshenziswa nge-extruder ukuyikhipha emgodini wokufa wesimo nobukhulu obunikeziwe, okubangela ukubola kwepulasitiki ukuze kutholwe umkhiqizo odingekayo. Njengoba induku ye-aluminium ithintwa izici ezihlukahlukene ezifana nezinga lokushisa, isivinini se-extrusion, inani le-deformation, kanye nesikhunta ngesikhathi senqubo yokuguqulwa, ukufana kokugeleza kwensimbi kunzima ukulawula, okuletha ubunzima obuthile ekwakhiweni kokubumba. Ukuze uqinisekise amandla esikhunta futhi ugweme ukuqhekeka, ukuwa, ukuqhekeka, njll., okulandelayo kufanele kugwenywe ekwakhiweni kwesigaba sephrofayela: ama-cantilever amakhulu, izimbobo ezincane, izimbobo ezincane, i-porous, i-asymmetrical, i-thick-walled, ubukhulu bodonga obungalingani, njll. Lapho siklama, kufanele siqale sanelise ukusebenza kwayo ngokusetshenziswa, ukuhlobisa, njll. Ngoba lapho abaklami bengenalo ulwazi lwenqubo ye-extrusion futhi bengaqondi imishini yenqubo efanele, futhi izidingo zenqubo yokukhiqiza ziphakeme kakhulu futhi ziqinile, izinga lokufaneleka lizoncishiswa, izindleko zizokwanda, futhi iphrofayili efanelekile ngeke ikhiqizwe. Ngakho-ke, umgomo womklamo wesigaba sephrofayela ye-aluminium ukusebenzisa inqubo elula ngangokunokwenzeka ngenkathi wanelisa ukwakheka kwayo okusebenzayo.

2. Amanye amathiphu ekwakhiweni kwephrofayili ye-aluminium

2.1 Isinxephezelo sephutha

Ukuvala kungenye yeziphambeko ezivamile ekukhiqizeni iphrofayela. Izizathu eziyinhloko yilezi:

(1) Amaphrofayili anezimbobo ezijulile zezigaba ngokuvamile azovala lapho ekhishiwe.

(2) Ukwelula nokuqondisa kwamaphrofayili kuzoqinisa ukuvala.

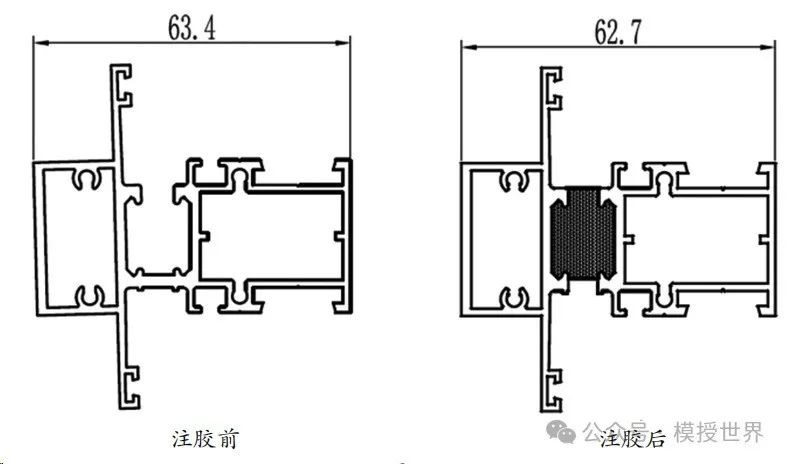

(3) Amaphrofayili afakwe ngeglue anezakhiwo ezithile nawo ayoba nokuvala ngenxa yokuncipha kwe-colloid ngemva kokujovwa kweglue.

Uma ukuvala okukhulunywe ngenhla kungekona okungathí sina, kungagwenywa ngokulawula izinga lokugeleza ngokuklama isikhunta; kodwa uma izici eziningana zibekwe phezulu futhi ukuklama kwesikhunta nezinqubo ezihlobene azikwazi ukuxazulula ukuvala, isinxephezelo sangaphambili singanikezwa ekuklanyeni kwesigaba esiphambene, okungukuthi, ukuvulwa kwangaphambili.

Inani lesinxephezelo sokuvulwa kwangaphambilini kufanele likhethwe ngokusekelwe esakhiweni saso esithile kanye nolwazi lokuvala lwangaphambilini. Ngalesi sikhathi, ukuklanywa komdwebo wokuvula isikhunta (ukuvulwa kwangaphambili) nomdwebo ophelile uhlukile (Umfanekiso 1).

2.2 Hlukanisa izigaba ezinosayizi omkhulu zibe izingxenye ezincane eziningi

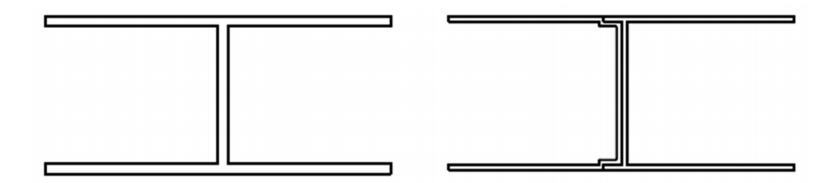

Ngokuthuthukiswa kwamaphrofayili amakhulu e-aluminium, imiklamo ye-cross-sectional yamaphrofayili amaningi iya ngokuya iba mikhudlwana futhi ibe mikhudlwana, okusho ukuthi uchungechunge lwemishini efana nama-extruder amakhulu, isikhunta esikhulu, izinduku ezinkulu ze-aluminium, njll. ziyadingeka ukuze zisekele, futhi izindleko zokukhiqiza zikhuphuka kakhulu. Kwezinye izigaba ezinosayizi omkhulu ezingafinyelelwa ngokuhlanganisa, kufanele zihlukaniswe zibe izingxenye ezimbalwa ezincane ngesikhathi sokuklama. Lokhu akukwazi ukunciphisa izindleko kuphela, kodwa futhi kwenze kube lula ukuqinisekisa ukugcwala, ukugoba, nokunemba (Umfanekiso 2).

2.3 Misa izimbambo eziqinisayo ukuze uthuthukise ukucaba kwayo

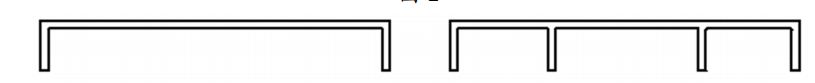

Izidingo zokulala zivame ukuhlangatshezwana nazo lapho uklama izigaba zephrofayela. Amaphrofayili e-spall-span kulula ukuqinisekisa ukuthi flatness ngenxa yamandla awo aphezulu esakhiwo. Amaphrofayili esikhathi eside azoncipha ngenxa yamandla adonsela phansi awo ngemva nje kokukhishwa, futhi ingxenye enengcindezi enkulu yokugoba phakathi izoba yi-concave kakhulu. Futhi, ngenxa yokuthi iphaneli yodonga yinde, kulula ukukhiqiza amagagasi, okuzokwenza kube kubi kakhulu ukuphumula kwendiza. Ngakho-ke, izakhiwo zepuleti eziyisicaba ezinkulu kufanele zigwenywe ekwakhiweni kwesigaba esiphambanayo. Uma kunesidingo, izimbambo eziqinisayo zingafakwa phakathi ukuze kuthuthukiswe ukucaba kwayo. (Umfanekiso 3)

2.4 Ukucubungula okwesibili

Enqubweni yokukhiqiza iphrofayili, ezinye izigaba zinzima ukuqedela ngokucutshungulwa kwe-extrusion. Ngisho noma kungenziwa, izindleko zokucubungula nokukhiqiza zizoba phezulu kakhulu. Ngalesi sikhathi, ezinye izindlela zokucubungula zingacatshangelwa.

Ikesi 1: Izimbobo ezinobubanzi obungaphansi kuka-4mm esigabeni sephrofayela zizokwenza isikhunta singanele emandleni, sonakale kalula, futhi kube nzima ukusicubungula. Kunconywa ukususa izimbobo ezincane futhi usebenzise ukubhoboza esikhundleni.

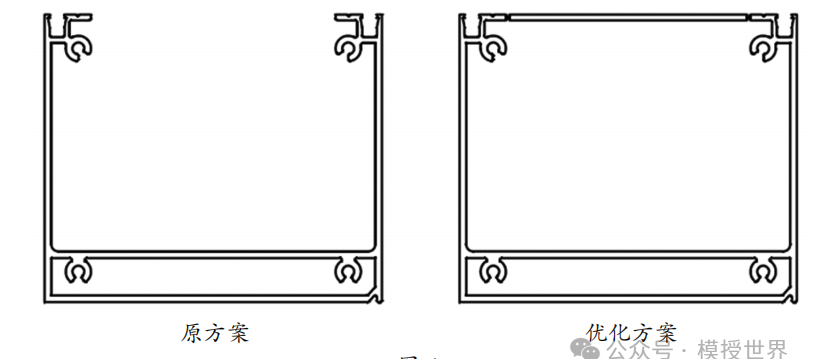

Icala lesi-2: Ukukhiqizwa kwemigodi evamile emise okwe-U akunzima, kodwa uma ukujula kwe-groove nobubanzi be-groove kudlula i-100mm, noma isilinganiso sobubanzi be-groove ukuya ekujuleni kwe-groove akunangqondo, izinkinga ezifana namandla anganele esikhunta nobunzima ekuqinisekiseni ukuvulwa kuzophinde kuhlangatshezwane nazo ngesikhathi sokukhiqiza. Lapho uklama isigaba sephrofayela, ukuvulwa kungabhekwa njengokuvaliwe, ukuze isikhunta sokuqala esiqinile esinamandla anganele singaguqulwa sibe isikhunta esihlukanisayo esizinzile, futhi ngeke kube nenkinga yokuvula i-deformation ngesikhathi se-extrusion, okwenza umumo ube lula ukuwugcina. Ngaphezu kwalokho, eminye imininingwane ingenziwa ekuxhumaneni phakathi kwemikhawulo emibili yokuvula ngesikhathi sokuklama. Isibonelo: setha amamaki amise okwe-V, ama-grooves amancane, njll., ukuze asuswe kalula ngesikhathi somshini wokugcina (Umfanekiso 4).

2.5 Inkimbinkimbi ngaphandle kodwa ilula ngaphakathi

Isikhunta se-aluminium extrusion profile singahlukaniswa sibe yisikhunta esiqinile kanye nesikhunta se-shunt ngokuya ngokuthi ingxenye ephambanayo inomgodi yini. Ukucutshungulwa kwesikhunta esiqinile kulula, kuyilapho ukucutshungulwa kwesikhunta se-shunt kuhilela izinqubo eziyinkimbinkimbi njengemigodi namakhanda ayinhloko. Ngakho-ke, ukucatshangelwa okugcwele kufanele kunikezwe ukuklama kwesigaba sephrofayela, okungukuthi, i-contour yangaphandle yesigaba ingaklanywa ukuba ibe yinkimbinkimbi kakhulu, futhi ama-grooves, izimbobo zokugoqa, njll. Ngale ndlela, kokubili ukucubungula nokugcinwa kwesikhunta kuzoba lula kakhulu, futhi izinga lokukhiqiza lizothuthukiswa.

2.6 Imajini ebekiwe

Ngemuva kwe-extrusion, amaphrofayili e-aluminium anezindlela ezihlukile zokwelashwa kwendawo ngokuya ngezidingo zamakhasimende. Phakathi kwazo, izindlela ze-anodizing kanye ne-electrophoresis zinomthelela omncane kusayizi ngenxa yongqimba lwefilimu elincanyana. Uma kusetshenziswa indlela yokwelapha engaphezulu ye-powder coating, i-powder izoqoqwa kalula emakhoneni nasemigodini, futhi ubukhulu bongqimba olulodwa bungafinyelela ku-100 μm. Uma lokhu kuyindawo yomhlangano, njengesilayidi, kuzosho ukuthi kunezingqimba ezi-4 ze-spray coating. Ubukhulu obufika ku-400 μm buzokwenza ukuhlanganisa kungenzeki futhi kuthinte ukusetshenziswa.

Ngaphezu kwalokho, njengoba inani le-extrusions likhula futhi isikhunta sigqoka, ubukhulu bezikhala zephrofayela buzoba buncane futhi bube buncane, kuyilapho ubukhulu besilayidi buyoba bukhulu futhi bukhulu, okwenza ukuhlangana kube nzima nakakhulu. Ngokusekelwe kulezi zizathu ezingenhla, amamajini afanelekile kufanele agcinwe ngokuvumelana nezimo ezithile ngesikhathi sokuklama ukuze kuqinisekiswe ukuhlangana.

2.7 Ukumakwa kokubekezelelana

Ngomklamo we-cross-section, umdwebo womhlangano ukhiqizwa kuqala bese umdwebo womkhiqizo wephrofayili ukhiqizwa. Umdwebo womhlangano olungile awusho ukuthi umdwebo womkhiqizo wephrofayili uphelele. Abanye abaklami bakushaya indiva ukubaluleka kokumakwa kobukhulu nokubekezelelana. Izindawo ezimakiwe ngokuvamile ubukhulu obudinga ukuqinisekiswa, njengokuthi: indawo yokuhlangana, ukuvulwa, ukujula kwemisele, ububanzi bemisele, njll., futhi kulula ukukala nokuhlola. Ngokubekezelela kobukhulu obujwayelekile, ileveli yokunemba ehambisanayo ingakhethwa ngokwezinga likazwelonke. Ezinye izilinganiso zomhlangano ezibalulekile zidinga ukumakwa ngamavelu athile okubekezelela emdwebeni. Uma ukubekezelelana kukhulu kakhulu, ukuhlangana kuzoba nzima kakhulu, futhi uma ukubekezelelana kukuncane kakhulu, izindleko zokukhiqiza zizokhula. Ibanga lokubekezelela elinengqondo lidinga ukuqongelelwa kokuhlangenwe nakho kwansuku zonke komklami.

2.8 Ukulungiswa okuningiliziwe

Imininingwane inquma impumelelo noma ukwehluleka, futhi kuyafana nangomklamo wezigaba ezihlukene zephrofayela. Izinguquko ezincane azikwazi nje ukuvikela isikhunta futhi zilawule izinga lokugeleza, kodwa futhi zithuthukise izinga eliphezulu futhi zandise izinga lokukhiqiza. Enye yezindlela ezivame ukusetshenziswa amakhona ajikelezayo. Amaphrofayili anwetshiwe awakwazi ukuba namakhona acijile ngokuphelele ngoba izintambo zethusi ezincanyana ezisetshenziswa ekusikeni kwezintambo nazo zinamadayamitha. Kodwa-ke, isivinini sokugeleza emakhoneni sihamba kancane, ukungqubuzana kukhulu, futhi ukucindezeleka kugxilile, ngokuvamile kunezimo lapho izimpawu ze-extrusion zisobala, ubukhulu bunzima ukulawula, futhi isikhunta sijwayele ukucwiliswa. Ngakho-ke, i-radius yokuzungeza kufanele inyuswe ngangokunokwenzeka ngaphandle kokuphazamisa ukusetshenziswa kwayo.

Ngisho noma ikhiqizwa umshini omncane we-extrusion, ubukhulu bodonga lwephrofayili akufanele bube ngaphansi kuka-0.8mm, futhi ubukhulu bodonga bengxenye ngayinye yesigaba akufanele buhluke izikhathi ezingaphezu kuka-4. Ngesikhathi sokuklama, imigqa ye-diagonal noma ukuguqulwa kwe-arc kungasetshenziswa ekushintsheni okungazelelwe kobukhulu bodonga ukuze kuqinisekiswe ukwakheka okujwayelekile kokukhipha kanye nokulungisa isikhunta kalula. Ukwengeza, amaphrofayili anezindonga ezincane anokuqina okungcono, futhi ubukhulu bodonga bamanye ama-gussets, ama-battens, njll. bungaba ngu-1mm. Kunezinhlelo zokusebenza eziningi zokulungiswa kwemininingwane ekuklanyeni, njengokulungisa ama-engeli, ukushintsha izinkomba, ukunciphisa ama-cantilever, ukukhulisa izikhala, ukuthuthukisa ukulinganisa, ukulungisa ukubekezelelana, njll. Ngamafuphi, ukuklama kwephrofayili ye-cross-section kudinga isifinyezo esiqhubekayo kanye nokuqanjwa okusha, futhi kucabangela ngokugcwele ubudlelwano nokuklama kwesikhunta, ukukhiqiza, nezinqubo zokukhiqiza.

3. Isiphetho

Njengomklami, ukuze uthole izinzuzo ezingcono kakhulu zezomnotho kusukela ekukhiqizweni kwephrofayili, zonke izici zawo wonke umjikelezo wempilo yomkhiqizo kufanele zicatshangelwe ngesikhathi sokuklanywa, okuhlanganisa izidingo zomsebenzisi, ukuklama, ukukhiqiza, ikhwalithi, izindleko, njll., silwele ukuzuza impumelelo yokuthuthukiswa komkhiqizo okokuqala ngqa. Lokhu kudinga ukulandelela nsuku zonke kokukhiqizwa komkhiqizo kanye nokuqoqwa nokuqoqwa kolwazi lomuntu siqu ukuze ubikezele imiphumela yedizayini futhi uyilungise kusenesikhathi.

Isikhathi sokuthumela: Sep-10-2024