1.Isingeniso

Ukukhanya kwezimoto kwaqala emazweni athuthukile futhi kwaqale kwaholwa izikhondlakhondla zezimoto zendabuko. Ngokuthuthuka okuqhubekayo, ithole umfutho obalulekile. Kusukela esikhathini lapho amaNdiya eqala ukusebenzisa ingxubevange ye-aluminium ukukhiqiza ama-crankshafts ezimoto kuya ekukhiqizeni okukhulu kwezimoto ze-Audi okokuqala ngqa ngo-1999, ingxubevange ye-aluminium ibone ukukhula okuqinile kwezinhlelo zezimoto ngenxa yezinzuzo zayo ezinjengokuminyana okuphansi, amandla athile aphezulu kanye nokuqina, ukuqina okuhle kanye nokunwebeka okukhulu, izinga eliphezulu lokuvuselelwa kabusha. Ngo-2015, ingxenye yokusetshenziswa kwe-aluminium alloy ezimotweni yayisingaphezu kwama-35%.

Ukukhanya kwezimoto zaseChina kwaqala eminyakeni engaphansi kweyi-10 edlule, futhi kokubili izinga lobuchwepheshe nesicelo kusasele ngemuva kwamazwe athuthukile njengeJalimane, i-United States, ne-Japan. Kodwa-ke, ngokuthuthukiswa kwezimoto ezintsha zamandla, ukukhanya kwezinto ezibonakalayo kuqhubeka ngokushesha. Ngokusebenzisa ukukhuphuka kwezimoto ezintsha ezisebenza ngamandla, ubuchwepheshe baseChina bokukhanyisa izinsimbi bukhombisa umkhuba wokuhlangana namazwe asethuthukile.

Imakethe yezimpahla ezingasindi yaseChina inkulu. Ngakolunye uhlangothi, uma kuqhathaniswa namazwe athuthukile phesheya, ubuchwepheshe be-lightweighting baseChina buqale sekwephuzile, kanti isisindo semoto yonke i-Curb sikhulu. Uma kucatshangelwa isilinganiso sengxenye yezinto ezingasindi emazweni angaphandle, sisekhona indawo eyanele yentuthuko eChina. Ngakolunye uhlangothi, kuqhutshwa izinqubomgomo, ukuthuthuka okusheshayo kwemboni yezimoto zamandla entsha yaseShayina kuzokhulisa isidingo sezinto ezingasindi futhi kukhuthaze izinkampani zezimoto ukuthi ziqhubekele phambili ekwenzeni izinto ezingasindi.

Ukwenziwa ngcono kwamazinga okukhipha umoya kanye nokusetshenziswa kukaphethiloli kuphoqa ukuthi kusheshiswe ukukhanyisa kwezimoto. I-China yasebenzisa ngokugcwele izindinganiso zokukhishwa kwegesi yase-China VI ngo-2020. Ngokuvumelana “Nendlela Yokuhlola Nezinkomba Zokusetshenziswa Kwezibaseli Zezimoto Ezihamba Ngabagibeli” kanye “Nebalazwe Lomgwaqo Lokonga Amandla kanye Nemoto Entsha Yamandla,” okuyindinganiso yokusetshenziswa kukaphethiloli engu-5.0 L/km. Uma kucatshangelwa isikhala esilinganiselwe sempumelelo enkulu kubuchwepheshe benjini kanye nokunciphisa igesi, ukuthatha izinyathelo ezingxenyeni zezimoto ezingasindi kunganciphisa ngempumelelo ukukhishwa kwezimoto kanye nokusetshenziswa kukaphethiloli. Ukwenziwa kwesisindo esilula sezimoto ezisebenza ngamandla amasha sekuyindlela ebalulekile ekuthuthukisweni kwemboni.

Ngo-2016, i-China Automotive Engineering Society yakhipha i-"Energy Saving and New Energy Vehicle Technology Roadmap," eyayihlela izici ezifana nokusetshenziswa kwamandla, uhla lokuhamba ngomkhumbi, kanye nezinto zokukhiqiza izimoto zamandla amasha kusukela ngo-2020 kuya ku-2030. Ukunciphisa kuzoba isiqondiso esibalulekile sokuthuthukiswa kwesikhathi esizayo kwezimoto ezintsha zamandla. I-Lightweighting ingakhuphula ibanga lokuhamba futhi ibhekane "nokukhathazeka kobubanzi" ezimotweni zamandla amasha. Ngokukhula kwesidingo sebanga lokuhamba ngomkhumbi, ukukhanya kwezimoto kuyaphuthuma, futhi ukuthengiswa kwezimoto zamandla amasha kukhule kakhulu eminyakeni yamuva. Ngokwezidingo zohlelo lwamaphuzu kanye ne “Mid-to-Long-Term Development Plan for the Automotive Industry,” kulinganiselwa ukuthi ngo-2025, ukuthengiswa kwezimoto zaseShayina zamandla amasha kuzodlula amayunithi ayizigidi eziyisi-6, nezinga lokukhula elihlanganisiwe ngonyaka lidlula ama-38%.

2.Izici ze-Aluminium Alloy kanye nezicelo

2.1 Izici ze-Aluminium Alloy

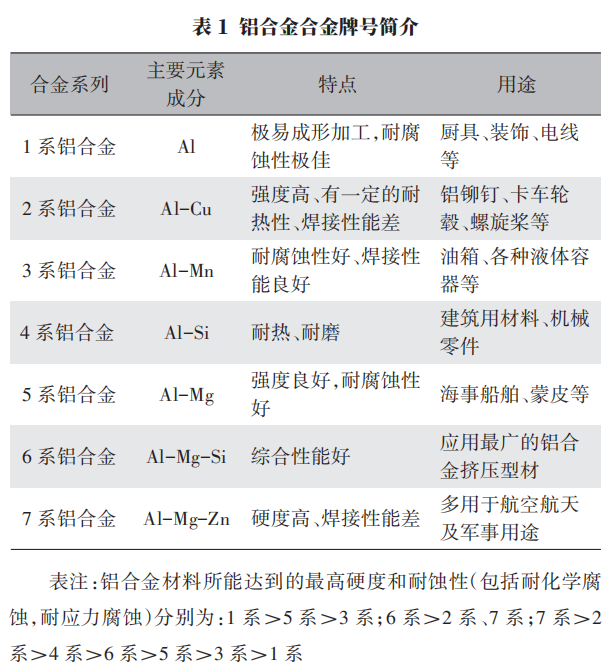

Ukuminyana kwe-aluminium ingxenye eyodwa kwezintathu kwensimbi, okwenza kube lula. Inamandla athile aphezulu, amandla amahle okukhipha, ukumelana nokugqwala okuqinile, nokugaywa kabusha okuphezulu. Ama-alloys e-aluminium abonakala ngokuyinhloko akhiwe nge-magnesium, ebonisa ukumelana nokushisa okuhle, izindawo ezinhle zokushisela, amandla amahle okukhathala, ukungakwazi ukuqiniswa ukwelashwa kokushisa, kanye nekhono lokwandisa amandla ngokusebenza okubandayo. Uchungechunge oluyisi-6 lubonakala ngokuthi lwakhiwe ngokuyinhloko i-magnesium ne-silicon, ne-Mg2Si njengesigaba esiyinhloko sokuqinisa. Ama-alloys asetshenziswa kakhulu kulesi sigaba yi-6063, 6061, kanye ne-6005A. Ipuleti le-aluminium engu-5052 i-AL-Mg series alloy aluminium plate, ene-magnesium njengento eyinhloko ehlanganisayo. Kuyinto esetshenziswa kabanzi kakhulu anti-rust aluminium alloy. Le alloy inamandla amakhulu, amandla aphezulu okukhathala, i-plasticity enhle kanye nokumelana nokugqwala, ayikwazi ukuqiniswa ukwelashwa kokushisa, ine-plasticity enhle emsebenzini wokuqina obandayo, i-plasticity ephansi emsebenzini obandayo ukuqina, ukumelana nokugqwala okuhle, kanye nezakhiwo ezinhle zokushisela. Isetshenziselwa ikakhulukazi izingxenye ezifana namapaneli aseceleni, izembozo zophahla, namapaneli eminyango. I-6063 aluminium alloy iyingxubevange eqinisayo ekwazi ukumelana nokushisa ochungechungeni lwe-AL-Mg-Si, ene-magnesium ne-silicon njengezici eziyinhloko ze-alloying. Iphrofayili ye-aluminium eqinisayo ekwazi ukumelana nokushisa enamandla aphakathi nendawo, esetshenziswa kakhulu ezingxenyeni zesakhiwo njengamakholomu namaphaneli aseceleni ukuze aphathe amandla. Isingeniso samabanga e-aluminium alloy sikhonjiswe kuThebula 1.

2.2 I-Extrusion Indlela Ebalulekile Yokwakha Ye-Aluminium Alloy

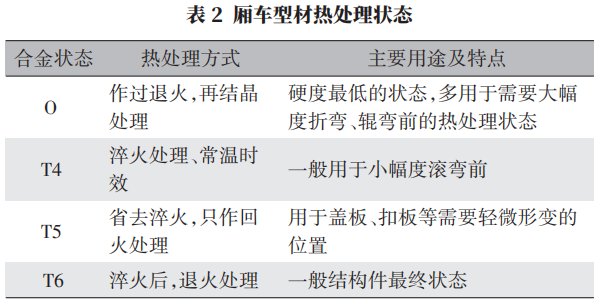

I-Aluminium alloy extrusion iyindlela yokwakha eshisayo, futhi yonke inqubo yokukhiqiza ihlanganisa ukwenza ingxubevange ye-aluminium ngaphansi kwengcindezi yokucindezela yezindlela ezintathu. Yonke inqubo yokukhiqiza ingachazwa kanje: a. I-aluminium namanye ama-alloys ayancibilika futhi aphonswe ku-billet edingekayo ye-aluminium alloy; b. Amabhilidi aseshisiwe afakwa emishinini yokukhishwa kwe-extrusion. Ngaphansi kwesenzo se-cylinder eyinhloko, i-aluminium alloy billet yenziwa ibe amaphrofayili adingekayo ngokusebenzisa umgodi wesikhunta; c. Ukuze kuthuthukiswe izakhiwo zemishini yamaphrofayili e-aluminium, ukwelashwa kwesixazululo kwenziwa ngesikhathi noma ngemuva kwe-extrusion, kulandelwa ukwelashwa kokuguga. Izakhiwo zemishini ngemuva kokwelashwa kokuguga ziyahlukahluka ngokuya ngezinto ezahlukahlukene kanye nemithetho yokuguga. Isimo sokwelashwa kokushisa kwamaphrofayili ohlobo lweloli sikhonjiswe kuThebula 2.

Imikhiqizo ekhishwe nge-aluminium alloy inezinzuzo ezimbalwa kunezinye izindlela zokwakha:

a. Ngesikhathi se-extrusion, insimbi ekhishweyo ithola ukucindezeleka okunamandla futhi okufana okufanayo kwezindlela ezintathu endaweni ye-deformation kunokuginqika nokubumba, ngakho-ke ingadlala ngokugcwele ipulasitiki yensimbi ecutshunguliwe. Ingasetshenziselwa ukucubungula izinsimbi okunzima ukonakala ezingakwazi ukucutshungulwa ngokugingqika noma ukufoja futhi ingasetshenziswa ukwenza izingxenye ezihlukahlukene eziyinkimbinkimbi ezingenalutho noma izingxenye eziqinile eziphambanayo.

b. Ngenxa yokuthi i-geometry yamaphrofayili e-aluminium ingahlukahluka, izingxenye zabo zinokuqina okuphezulu, okungathuthukisa ukuqina komzimba wemoto, ukunciphisa izici zayo ze-NVH, futhi kuthuthukise izici zokulawula okuguquguqukayo kwemoto.

c. Imikhiqizo ene-extrusion ephumelelayo, ngemva kokucisha nokuguga, inamandla e-longitudinal aphezulu kakhulu (R, Raz) kunemikhiqizo ecutshungulwe ngezinye izindlela.

d. Ingaphezulu lemikhiqizo ngemva kwe-extrusion linombala omuhle nokumelana nokugqwala okuhle, okuqeda isidingo sokunye ukwelashwa okuqeda ukugqwala.

e. Ukucutshungulwa kwe-Extrusion kunokuguquguquka okukhulu, izindleko eziphansi zamathuluzi nesikhunta, nezindleko eziphansi zokushintsha ukwakheka.

f. Ngenxa yokulawulwa kwezingxenye eziphambanayo zephrofayili ye-aluminium, izinga lokuhlanganiswa kwengxenye lingakhuphuka, inani lezingxenye lingancishiswa, futhi imiklamo ehlukene ye-cross-section ingafinyelela ukuma okuqondile kwe-welding.

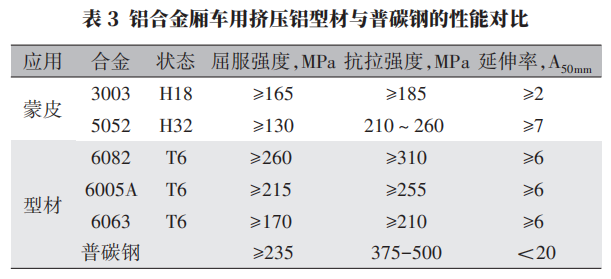

Ukuqhathaniswa kokusebenza phakathi kwamaphrofayela e-aluminium extruded wamaloli ohlobo lwebhokisi nensimbi ye-carbon carbon kuboniswa kuThebula 3.

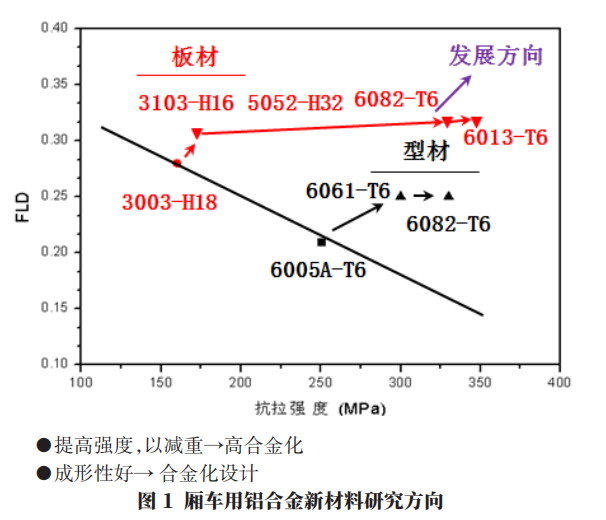

I-Next Development Direction yamaphrofayili e-Aluminium Alloy Yamaloli ohlobo lwe-Box: Ukuthuthukisa ngokuqhubekayo amandla wephrofayela nokuthuthukisa ukusebenza kwe-extrusion. Isiqondiso socwaningo sezinto ezintsha zamaphrofayili e-aluminium alloy yamaloli ohlobo lwamabhokisi kukhonjisiwe kuMfanekiso 1.

3.I-Aluminium Alloy Box Isakhiwo Seloli, Ukuhlaziya Amandla, Nokuqinisekisa

3.1 I-Aluminium Alloy Box Isakhiwo Seloli

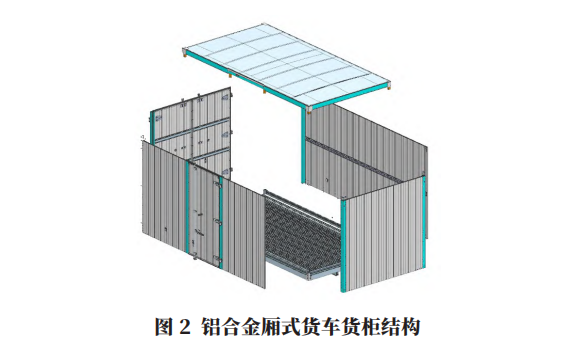

I-container yeloli yebhokisi ngokuyinhloko iqukethe umhlangano wephaneli yangaphambili, umhlangano wephaneli yesokunxele nesokudla, umhlangano wangemuva wephaneli yomnyango wangemuva, umhlangano waphansi, umhlangano ophahleni, kanye nama-bolts amise okwe-U, onogada baseceleni, onogada bangemuva, izigxobo zodaka, nezinye izesekeli ezixhunywe ku-chassis yesigaba sesibili. Izigxobo zomzimba webhokisi, izinsika, imishayo eseceleni, namaphaneli eminyango enziwe ngamaphrofayili e-aluminium alloy extruded, kuyilapho amaphaneli aphansi nawophahla enziwe ngamapuleti angama-5052 e-aluminium alloy flat. Isakhiwo seloli yebhokisi le-aluminium alloy kuboniswe kuMfanekiso 2.

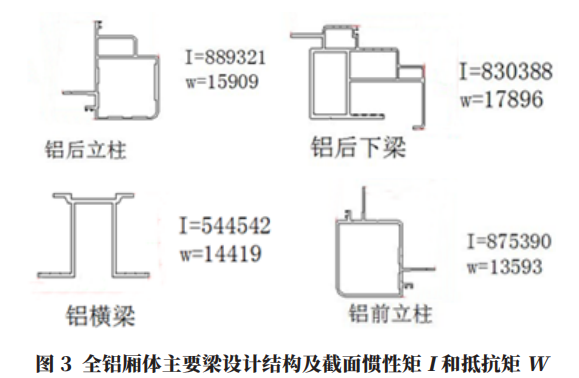

Ukusebenzisa inqubo ye-hot extrusion ye-6 series aluminium alloy ingakha iziphambano eziyinkimbinkimbi ezingenalutho, idizayini yamaphrofayili e-aluminium eneziphambano eziyinkimbinkimbi ingasindisa izinto ezibonakalayo, ihlangabezane nezidingo zamandla omkhiqizo nokuqina, futhi ihlangabezane nezidingo zokuxhumanisa phakathi kwezingxenye ezihlukahlukene. Ngakho-ke, uhlaka oluyinhloko lomklamo wohlaka kanye nezikhathi zesigaba se-inertia I kanye nezikhathi zokumelana no-W kuboniswa kuMfanekiso 3.

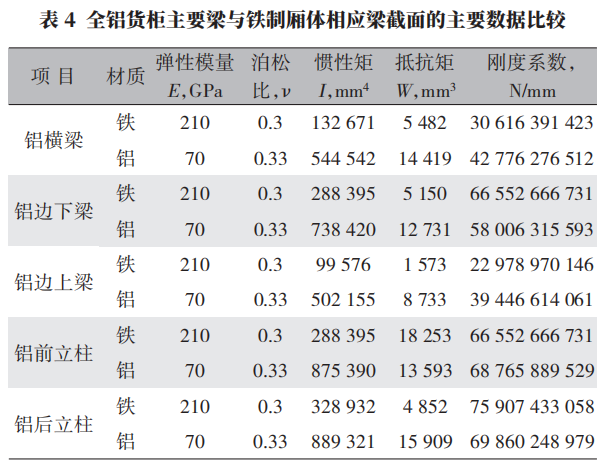

Ukuqhathaniswa kwedatha eyinhloko kuThebula lesi-4 kubonisa ukuthi izikhathi zesigaba se-inertia kanye nezikhathi zokumelana zephrofayili ye-aluminium eklanyelwe zingcono kunedatha ehambisanayo yephrofayili yensimbi eyenziwe ngensimbi. Idatha ye-coefficient yokuqina icishe ifane naleyo yephrofayili yesigxobo sensimbi ehambisanayo, futhi yonke ihlangabezana nezidingo zokuguqulwa.

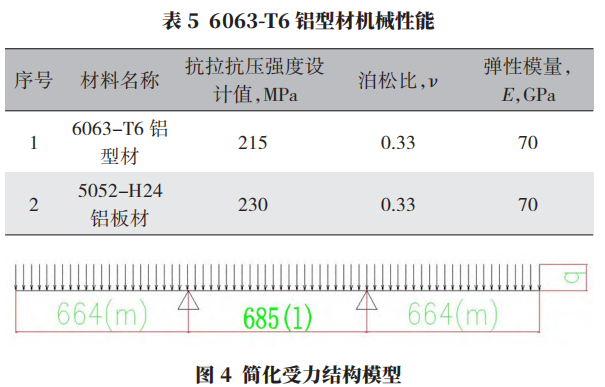

3.2 Ukubalwa kokucindezeleka okukhulu

Ukuthatha ingxenye eyisihluthulelo ethwala umthwalo, i-crossbeam, njengento, ukucindezeleka okuphezulu kubalwa. Umthwalo olinganiselwe u-1.5 t, futhi i-crossbeam yenziwe ngephrofayili ye-aluminium ye-6063-T6 ene-mechanical properties njengoba kuboniswe kuThebula 5. I-beam yenziwe lula njengesakhiwo se-cantilever sokubala amandla, njengoba kuboniswe ku-Figure 4.

Kuthatha i-344mm ye-span beam, umthwalo ocindezelayo ensikeni ubalwa njengo-F=3757 N ngokusekelwe ku-4.5t, owuphinda kathathu umthwalo omile ojwayelekile. q=F/L

lapho q ukucindezeleka kwangaphakathi kwesigxobo ngaphansi komthwalo, N / mm; U-F ungumthwalo othwalwa ugongolo, obalwa ngokusekelwe izikhathi ezi-3 zomthwalo omile ojwayelekile, ongu-4.5 t; L ubude be-beam, mm.

Ngakho-ke, ingcindezi yangaphakathi q ithi:

Ifomula yokubala ukucindezeleka imi kanje:

Isikhathi esiphezulu sithi:

Ukuthatha inani eliphelele lesikhathi, M=274283 N·mm, ukucindezeleka okuphezulu okungu-σ=M/(1.05×w)=18.78 MPa, kanye nenani eliphezulu lokucindezeleka elingu-σ<215 MPa, elihlangabezana nezimfuneko.

3.3 Izici Zokuxhuma Zezingxenye Ezihlukahlukene

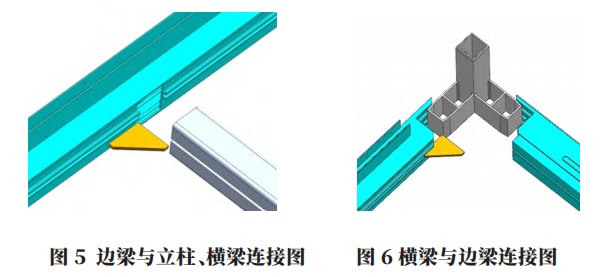

I-aluminium alloy inezakhiwo zokushisela ezimbi, futhi amandla ayo okushisela ama-60% kuphela wamandla esisekelo. Ngenxa yokumbozwa kongqimba lwe-Al2O3 endaweni ye-aluminium alloy, indawo yokuncibilika ye-Al2O3 iphezulu, kuyilapho indawo yokuncibilika ye-aluminium iphansi. Uma i-aluminium alloy ishiselwe, i-Al2O3 engaphezulu kufanele iphuke ngokushesha ukuze kushiselwe. Ngesikhathi esifanayo, okusele kwe-Al2O3 kuzohlala kusixazululo se-aluminium alloy, okuthinta isakhiwo se-aluminium alloy nokunciphisa amandla e-aluminium alloy welding point. Ngakho-ke, lapho uklama isitsha se-aluminium yonke, lezi zici zicatshangelwa ngokugcwele. I-Welding iyindlela eyinhloko yokumisa, futhi izingxenye eziyinhloko ezithwala imithwalo zixhunywe ngama-bolts. Ukuxhumana okufana ne-riveting kanye ne-dovetail structure kukhonjiswe kuMfanekiso 5 no-6.

Isakhiwo esiyinhloko somzimba webhokisi le-aluminiyamu yonke samukela isakhiwo esinemishayo evundlile, izinsika eziqondile, imishayo eseceleni, nemishayo esemaphethelweni ehlanganayo. Kunamaphoyinti amane okuxhumana phakathi komugqa ngamunye ovundlile kanye nensika eqondile. Izindawo zokuxhuma zifakwe ama-serrated gaskets ukuze abe nezikhala ngonqenqema oluyisiyingi lomsebe ovundlile, okuvimbela ngempumelelo ukushelela. Amaphoyinti ayisishiyagalombili ekhona axhunywe ngokuyinhloko ngokufaka okuphakathi kwensimbi, okuhlanganiswe namabhawodi nama-rivets azikhiyayo, futhi aqiniswe amapuleti e-aluminium angunxantathu angu-5mm ashiselwe ngaphakathi kwebhokisi ukuze kuqiniswe izindawo zamakhona ngaphakathi. Ukubukeka kwangaphandle kwebhokisi akunayo i-welding noma izindawo zokuxhuma eziveziwe, okuqinisekisa ukubukeka okuphelele kwebhokisi.

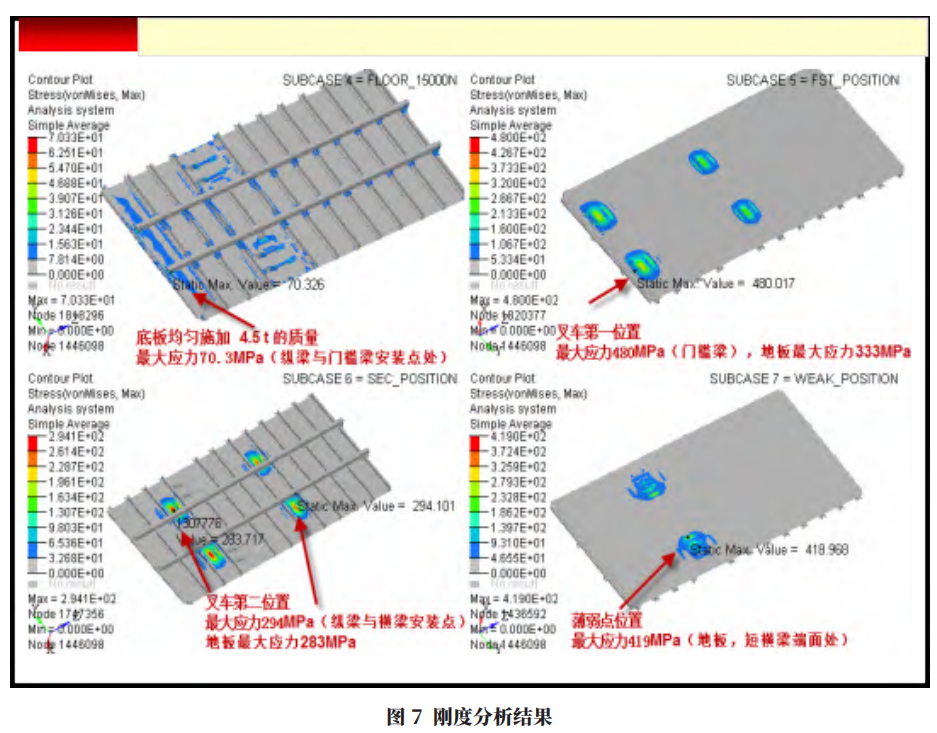

3.4 SE I-Synchronous Engineering Technology

Ubuchwepheshe bobunjiniyela bokuvumelanisa be-SE busetshenziselwa ukuxazulula izinkinga ezibangelwa ukuchezuka kosayizi omkhulu oqoqiwe wezingxenye ezifanayo ezisebhokisini lomzimba kanye nobunzima bokuthola izimbangela zezikhala nokuhluleka kokucaba. Ngokuhlaziywa kwe-CAE (bheka Umfanekiso 7-8), ukuhlaziywa kokuqhathanisa kwenziwa nezindikimba zamabhokisi enziwe ngensimbi ukuze kuhlolwe amandla nokuqina kwebhokisi lebhokisi, ukuthola amaphuzu abuthakathaka, futhi kuthathwe izinyathelo zokuthuthukisa nokuthuthukisa uhlelo lokuklama ngempumelelo.

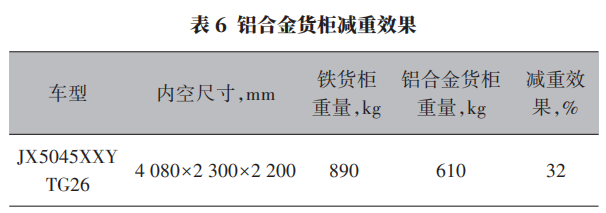

I-4.Lightweighting Effect ye-Aluminium Alloy Box Truck

Ngokungeziwe emzimbeni webhokisi, ama-alloys e-aluminium angasetshenziswa ukufaka esikhundleni sensimbi yezingxenye ezihlukahlukene zeziqukathi zamaloli zohlobo lwebhokisi, njengama-mudguards, onogada abangemuva, onogada abaseceleni, izintambo zezicabha, amahinge eminyango, nemiphetho yamaphinifa angemuva, kuzuzwe ukuncipha kwesisindo ngo-30% kuya ku-40% endaweni yezimpahla. Umthelela wokunciphisa isisindo wesiqukathi sempahla esingu-4080mm×2300mm×2200mm esingenalutho siboniswa kuThebula 6. Lokhu ngokuyisisekelo kuzixazulula izinkinga zesisindo eseqile, ukungahambisani nezimemezelo, kanye nezingozi zokulawula zezindawo zendabuko zempahla ezenziwe ngensimbi.

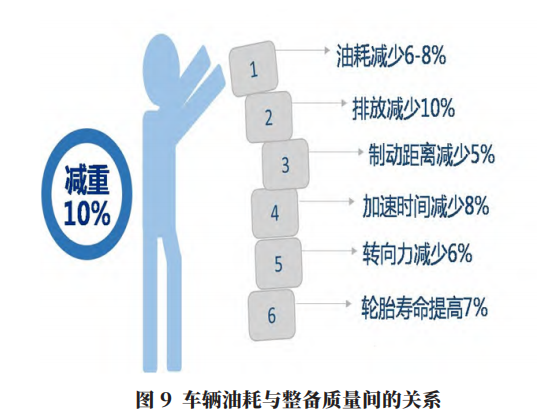

Ngokufaka esikhundleni sensimbi yendabuko ama-alloys e-aluminium ezingxenyeni zezimoto, akukhona nje kuphela ukuthi kungafinyelelwa imiphumela emihle kakhulu yokukhanya, kodwa futhi kungaba nomthelela ekongeni uphethiloli, ekunciphiseni ukungcola, kanye nokusebenza kwemoto okuthuthukisiwe. Njengamanje, kunemibono eyahlukene mayelana negalelo le-lightweight ekongeni uphethiloli. Imiphumela yocwaningo lwe-International Aluminium Institute ikhonjisiwe kuMfanekiso 9. Njalo ngo-10% ukuncipha kwesisindo semoto kunganciphisa ukusetshenziswa kukaphethiloli ngo-6% kuya ku-8%. Ngokwezibalo zasekhaya, ukwehlisa isisindo semoto yomgibeli ngayinye ngo-100 kg kunganciphisa ukusetshenziswa kukaphethiloli ngo-0.4 L/100 km. Umnikelo we-lightweighting ekongeni uphethiloli usekelwe emiphumeleni etholwe ezindleleni ezihlukene zocwaningo, ngakho-ke kunokwehluka okuthile. Kodwa-ke, ukukhanya kwezimoto kunomthelela omkhulu ekwehliseni ukusetshenziswa kukaphethiloli.

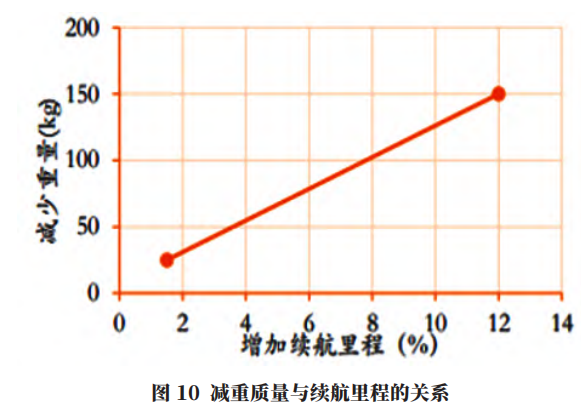

Ezimotweni zikagesi, umphumela wokukhanya ubonakala nakakhulu. Njengamanje, ukuminyana kwamandla eyunithi yamabhethri anamandla emoto kagesi kuhluke kakhulu kulezo zezimoto zikaphethiloli eziwuketshezi ezivamile. Isisindo sesistimu yamandla (kuhlanganise nebhethri) yezimoto zikagesi ngokuvamile zibalelwa ku-20% kuya ku-30% wesamba sesisindo semoto. Ngesikhathi esifanayo, ukwephula ibhodlela lokusebenza kwamabhethri kuyinselele yomhlaba wonke. Ngaphambi kokuba kube khona impumelelo enkulu kubuchwepheshe bebhethri obusebenza kakhulu, ukwenza ukukhanya kuyindlela ephumelelayo yokuthuthukisa uhla lokuhamba lwezimoto zikagesi. Kuwo wonke amakhilogremu angu-100 ekwehliswa kwesisindo, uhla lokuhamba lwezimoto zikagesi lungakhushulwa ngo-6% kuya ku-11% (ubudlelwane phakathi kokunciphisa isisindo kanye nobubanzi bokuhamba buboniswa kuMfanekiso 10). Njengamanje, uhla lokuhamba lwezimoto zikagesi ezimsulwa azikwazi ukuhlangabezana nezidingo zabantu abaningi, kodwa ukunciphisa isisindo ngenani elithile kungathuthukisa kakhulu ibanga lokuhamba, kudambise ukukhathazeka kobubanzi nokuthuthukisa ulwazi lomsebenzisi.

5.Isiphetho

Ngaphezu kwesakhiwo se-aluminiyamu yonke yeloli yebhokisi le-aluminium alloy eyethulwe kulesi sihloko, kunezinhlobo ezahlukene zamaloli amabhokisi, njengamaphaneli e-aluminium honeycomb, amapuleti e-aluminium buckle, amafreyimu e-aluminium + izikhumba ze-aluminium, neziqukathi ze-iron-aluminium hybrid cargo. Zinezinzuzo zesisindo sokukhanya, amandla athile aphezulu, nokumelana nokugqwala okuhle, futhi azidingi upende we-electrophoretic ukuze kuvikelwe ukugqwala, ezinciphisa umthelela wendawo kapende we-electrophoretic. Iloli lebhokisi le-aluminium eliyingxubevange lixazulula izinkinga zesisindo eseqile, ukungathobeli izimemezelo, kanye nezingozi zokulawula zezindawo zezimpahla zendabuko ezenziwe ngensimbi.

I-Extrusion iyindlela ebalulekile yokucubungula yama-alloys e-aluminium, futhi amaphrofayili e-aluminium anezakhiwo ezinhle kakhulu zemishini, ngakho-ke ukuqina kwesigaba sezingxenye kuphezulu kakhulu. Ngenxa ye-variable cross-section, ama-alloys e-aluminium angakwazi ukufeza inhlanganisela yemisebenzi yezingxenye eziningi, ayenze ibe impahla enhle yokukhanya kwezimoto. Kodwa-ke, ukusetshenziswa okubanzi kwama-alloys e-aluminium kubhekene nezinselele njengokungakwazi ukuklama okwanele kwezingxenye zezimpahla ze-aluminium ingxubevange, izinkinga zokwakheka nokushisela, kanye nezindleko eziphezulu zokuthuthukiswa nokukhushulwa kwemikhiqizo emisha. Isizathu esikhulu kusewukuthi ingxubevange ye-aluminium ibiza ngaphezu kwensimbi ngaphambi kokuba i-ecology yokugaya kabusha yama-alloys e-aluminium ivuthwe.

Sengiphetha, ububanzi bokusetshenziswa kwama-alloys e-aluminium ezimotweni buzoba banzi, futhi ukusetshenziswa kwawo kuzoqhubeka nokwanda. Ezinkambisweni zamanje zokonga amandla, ukuncishiswa kwe-emissions, kanye nokuthuthukiswa kwemboni yezimoto zamandla amasha, ngokuqonda okujulile kwezakhiwo ze-aluminium alloy kanye nezixazululo ezisebenzayo ezinkingeni zokufakwa kwe-aluminium alloy, izinto ze-aluminium extrusion zizosetshenziswa kabanzi ekukhanyeni kwezimoto.

Ihlelwe nguMay Jiang evela kwaMAT Aluminium

Isikhathi sokuthumela: Jan-12-2024