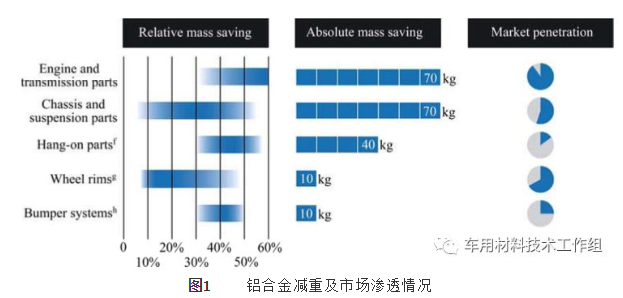

Imboni yezimoto yaseYurophu idume ngokuthuthuka kwayo nokusungula izinto ezintsha. Ngokugqugquzelwa kwezinqubomgomo zokonga ugesi kanye nokunciphisa ukungcola, ukuze kwehliswe ukusetshenziswa kukaphethiloli kanye nokukhishwa kwe-carbon dioxide, ama-alloys e-aluminium athuthukisiwe futhi aklanywe ngendlela entsha asetshenziswa kabanzi ekwakhiweni kwezimoto. Ngokwezibalo, eminyakeni eyishumi edlule, isilinganiso senani le-aluminium elisetshenziswa ezimotweni zabagibeli liye laphindeka kabili, futhi ukuncishiswa kwesisindo se-aluminium alloys kuboniswe kuMfanekiso 1 ngezansi. Ngokusekelwe emicabangweni emisha yokuklama, le threndi izoqhubeka eminyakeni embalwa ezayo.

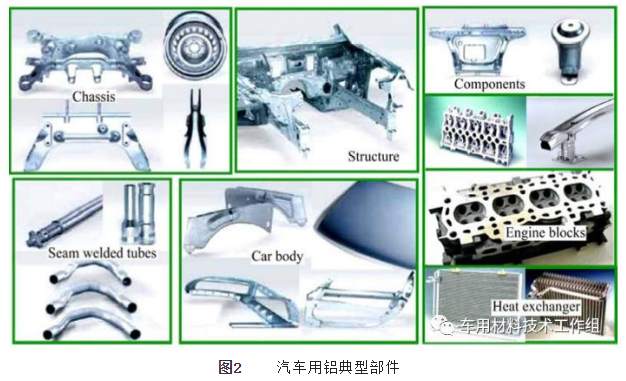

Enqubweni yokuthuthukiswa kwe-lightweight, ama-alloys e-aluminium abhekene nokuncintisana okunamandla nezinye izinto ezintsha, njengensimbi enamandla amakhulu, engakwazi ukugcina amandla aphezulu ngemva komklamo owenziwe ngezindonga ezincane. Ngaphezu kwalokho, kukhona i-magnesium, i-titanium, ingilazi noma i-carbon fiber composite materials, ezokugcina sezivele zisetshenziswa kabanzi ku-aerospace. Manje umqondo womklamo wezinto eziningi usuhlanganiswe ekwakhiweni kwezimoto, futhi kwenziwa imizamo yokusebenzisa izinto ezifanele ezingxenyeni ezifanele. Inselele ebaluleke kakhulu inkinga yokuxhumana nokuphathwa kwendawo, futhi izixazululo ezihlukahlukene ziye zathuthukiswa, njenge-injini block kanye nezingxenye zesitimela samandla, ukwakhiwa kohlaka (Audi A2, A8, BMW Z8, Lotus Elise), ukwakheka kwepuleti elincane (Honda NSX, Jaguar, Rover), ukumiswa (ikilasi le-DC-E, i-Renault, i-Peugeot) nezinye izakhi zesakhiwo. Umfanekiso 2 ubonisa izingxenye ze-aluminium ezisetshenziswa ezimotweni.

BIW Design Isu

I-body-in-white iyingxenye esindayo kunazo zonke zemoto evamile, ibalwa ku-25% kuya ku-30% wesisindo semoto. Kunemiklamo emibili yesakhiwo ekwakhiweni komzimba okumhlophe.

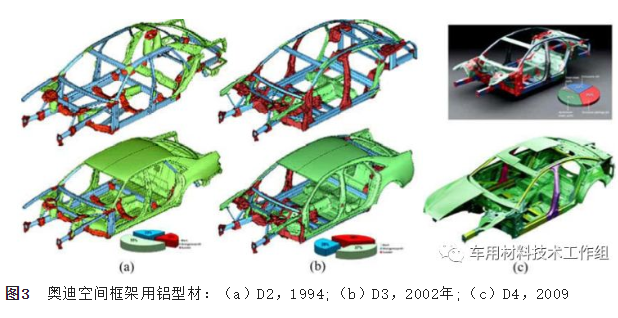

1."Idizayini yozimele wesikhala sephrofayela" yezimoto ezincane nezinosayizi omaphakathi: I-Audi A8 iyisibonelo esivamile, umzimba omhlophe unesisindo esingu-277 kg, uqukethe amaphrofayili angu-59 (61 kg), ama-castings angu-31 (39 kg) kanye ne-170 sheet metal (177 kg). Ahlanganiswa ne-riveting, i-MIG welding, i-laser welding, enye i-hybrid welding, i-gluing, njll.

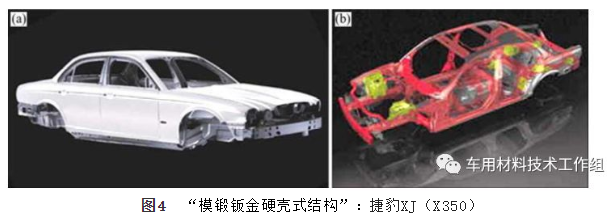

2. "Isakhiwo se-Die-forged sheet metal monocoque" sezinhlelo zokusebenza zemoto ezinomthamo ophakathi nendawo ukuya omkhulu: isibonelo, imodeli ye-Jaguar XJ (X350), 2002 (njengoba kukhonjisiwe kumfanekiso 4 ngezansi), isisindo esingu-295 kg "isakhiwo somzimba esigxiviziwe se-monocoque" umzimba-omhlophe wawunamaphrofayili angu-22 (21 kg), ama-castings angu-15 (15 kg) kanye nezingxenye zensimbi ezingamashidi angu-273 (259 kg). Izindlela zokuxhuma zifaka i-bonding, riveting, ne-MIG welding.

Ukusetshenziswa kwe-Aluminium Alloy emzimbeni

1. Ingxubevange ye-Al-Mg-Si eqinisiwe

Ama-alloys angu-6000 ochungechunge aqukethe i-magnesium ne-silicon futhi okwamanje asetshenziswa kumashidi omzimba wezimoto njenge-A6016, A6111 ne-A6181A. E-Europe, i-1-1.2mm EN-6016 inokwakheka okuhle kakhulu nokumelana nokugqwala futhi isetshenziswa kabanzi.

2. Ingxubevange ye-Al-Mg-Mn engelaphekayo engashisi

Ngenxa yokuqina kwayo okuphezulu, ama-alloys e-Al-Mg-Mn akhombisa ukuhleleka okuhle kakhulu namandla aphezulu, futhi asetshenziswa kabanzi kumashidi agingqiwe ashisayo ezimoto kanye namashubhu ane-hydroformed. Ukusetshenziswa ku-chassis noma amasondo kusebenza nakakhulu ngoba ukuncishiswa kwenqwaba yezingxenye ezihambayo ezingaphumi futhi kuthuthukisa ukunethezeka kokushayela futhi kunciphisa amazinga omsindo.

3. Iphrofayili ye-Aluminium

EYurophu, imiqondo yemoto emisha ngokuphelele yahlongozwa ngokusekelwe ekwakhiweni kwephrofayili ye-aluminium, isibonelo, amafreyimu e-aluminium alloy kanye nezakhiwo eziyinkimbinkimbi. Amandla abo amakhulu emiklamo eyinkimbinkimbi nokuhlanganiswa okusebenzayo abenza bafaneleke kakhulu ekukhiqizeni uchungechunge olungabizi kakhulu. Ngenxa yokuthi ukucisha kuyadingeka ngesikhathi se-extrusion, amandla aphakathi nendawo angu-6000 namandla aphezulu angu-7000 ama-alloys aqinile asetshenziswayo. Ukwakheka namandla okugcina kulawulwa ngokuqiniswa kweminyaka ngokufudumeza okulandelayo. Amaphrofayili e-aluminium alloy asetshenziswa kakhulu ekwakhiweni kohlaka, imishayo yokuphahlazeka nezinye izinto zokuphahlazeka.

4. Aluminium Casting

Ama-castings yizingxenye ze-aluminium ezisetshenziswa kakhulu ezimotweni, njengamabhulokhi enjini, amakhanda amasilinda nezinto ezikhethekile ze-chassis. Ngisho nezinjini zikadizili, ezikhuphule kakhulu isabelo sazo emakethe eYurophu, sezishintshela ekusakazeni kwe-aluminium ngenxa yokwanda kwezidingo zamandla nokuhlala isikhathi eside. Ngesikhathi esifanayo, ukukhishwa kwe-aluminium nakho kuyasetshenziswa ekwakhiweni kohlaka, izingxenye ze-shaft kanye nezingxenye zesakhiwo, futhi ukukhishwa kwe-high-pressure yama-alloys e-aluminium entsha ye-AlSiMgMn kuzuze amandla aphezulu kanye ne-ductility.

I-Aluminium iyimpahla yokuzikhethela ezinhlelweni eziningi zezimoto ezifana ne-chassis, umzimba kanye nezakhi eziningi zesakhiwo ngenxa yokuminyana kwayo okuphansi, ukwakheka okuhle nokumelana nokugqwala okuhle. I-Aluminium esetshenziswa ekwakhiweni kwesakhiwo somzimba ingafinyelela okungenani u-30% wokunciphisa isisindo ngaphansi kwesisekelo sokuhlangabezana nezidingo zokusebenza. Futhi, ama-alloys e-aluminium angasetshenziswa ezingxenyeni eziningi zekhava yamanje. Kwezinye izimo ezinezidingo zamandla aphezulu, ama-alloys ochungechunge angu-7000 asengakwazi ukugcina izinzuzo zekhwalithi. Ngakho-ke, ekusetshenzisweni kwevolumu ephezulu, izixazululo zokunciphisa isisindo se-aluminium alloy ziyindlela yokonga kakhulu.

Ihlelwe nguMay Jiang evela kwaMAT Aluminium

Isikhathi sokuthumela: Dec-08-2023