1 Incazelo yezenzakalo zokukhubazeka

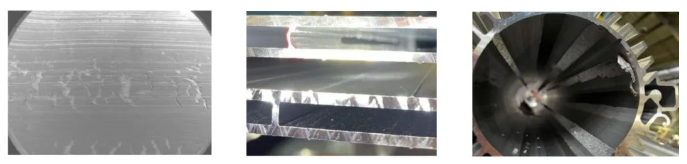

Lapho ukhipha amaphrofayili we-cavity, ikhanda lihlala liklwejwa, futhi izinga elingasebenzi kahle licishe libe ngu-100%. Umumo ojwayelekile onesici wephrofayili umi kanje:

2 Ukuhlaziya kokuqala

2.1 Uma sibheka indawo yesici kanye nokuma kwesici, i-delamination kanye nokuxebuka.

2.2 Imbangela: Ngenxa yokuthi isikhumba sentonga yokubungula yangaphambili sasigoqelwe esikhaleni sesikhunta, ukungafani, ukuxebuka, nezinto ezibolile zavela ekhanda elikhiphayo lenduku yokuphonsa elandelayo.

3 Ukutholwa nokuhlaziya

Ukuskena kwe-electronic microscope yokukhulisa okuphansi, ukukhuliswa okuphezulu kanye nokukhubazeka okuyingxenye ye-casting rod kwenziwa ngokulandelanayo.

3.1 Induku yokuphonsa ukukhuliswa okuphansi

11 inch 6060 casting induku yokukhulisa okuphansi Ukuhlukaniswa kobuso 6.08mm

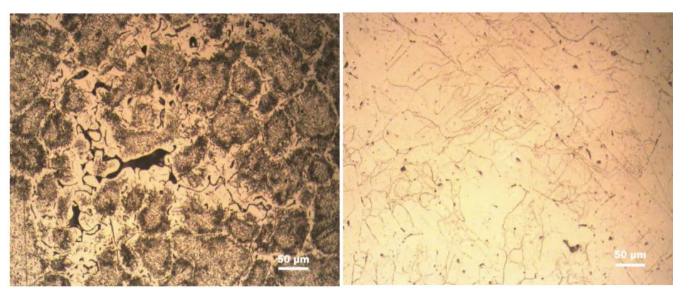

3.2 Induku yokuphonsa ukukhuliswa okuphezulu

Eduze kwendawo yomugqa wokuhlukanisa isendlalelo se-epidermis

Induku yokuphonsa 1/2 isikhundla

3.3 Ukuskena amaphutha ngesibonakhulu se-electron

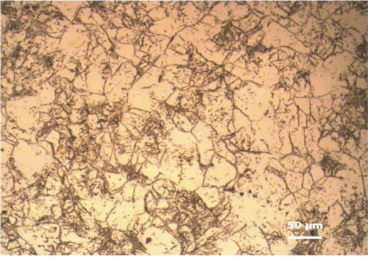

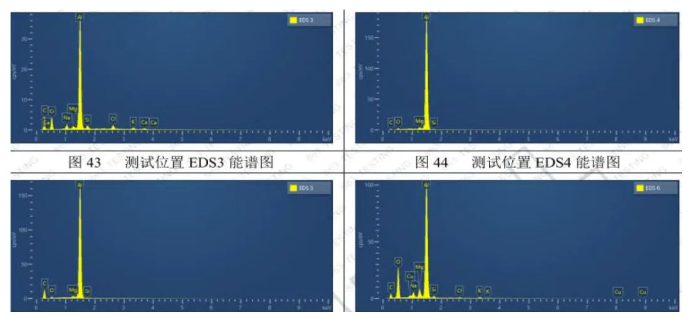

Khulisa indawo enesici izikhathi ezingama-200

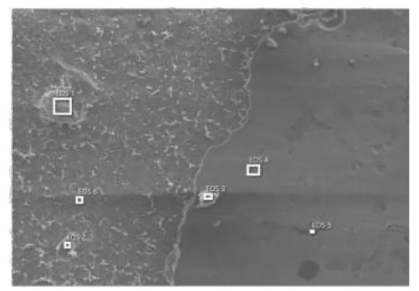

Umdwebo we-spectrum yamandla

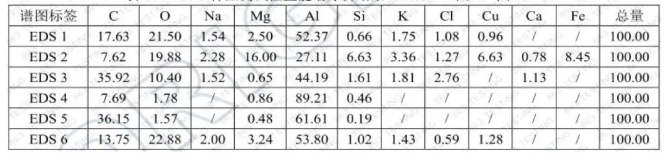

Ukuhlaziywa kwengxenye ye-EDS

4 Incazelo emfushane yemiphumela yokuhlaziya

4.1 Ungqimba oluwugqinsi oluyi-6mm lokuhlukanisa luvela endaweni ekhulisa kancane yenduku yokuphonsa. Ukuhlukaniswa kuyi-eutectic ye-low-melting-point, ebangelwa ukupholisa kancane kokusakazwa. Ukubukeka kwe-macroscopic kumhlophe futhi kuyacwebezela, futhi umngcele one-matrix ucacile;

4.2 Ukukhulisa okuphezulu kukhombisa ukuthi kunezimbotshana onqenqemeni lwenduku yokuphonsa, okubonisa ukuthi amandla okupholisa aphakeme kakhulu futhi uketshezi lwe-aluminium aluphakelwa ngokwanele. Ku-interface phakathi kwesendlalelo sokuhlukanisa kanye ne-matrix, isigaba sesibili asivamile kakhulu futhi asiqhubeki, okuyindawo empofu kakhulu. Ububanzi benduku yokuphonsa yi-1/2 Ukuba khona kwama-dendrites endaweni kanye nokusatshalaliswa okungalingani kwezingxenye kuphinde kubonise ukuhlukaniswa kwesendlalelo esingaphezulu kanye nezimo zokukhula kokuqondisa kwama-dendrites;

4.3 Isithombe sesici esiphambanayo emkhakheni we-200x wokubuka isibonakhulu se-electron sibonisa ukuthi indawo ilukhuni lapho isikhumba sixebuka khona, futhi ingaphezulu libushelelezi lapho isikhumba singaxebuki. Ngemva kokuhlaziywa kokwakheka kwe-EDS, amaphuzu 1, 2, 3, kanye ne-6 yizindawo ezinesici, futhi ukwakheka kuqukethe i-C1, K, kanye ne-Na yizici ezintathu, okubonisa ukuthi kukhona ingxenye ye-ejenti yokucwenga ekubunjweni;

4.4 Izingxenye ze-C kanye no-0 ezingxenyeni ezikumaphuzu 1, 2, no-6 ziphakeme, futhi izingxenye ze-Mg, Si, Cu, ne-Fe endaweni yesi-2 ziphakeme kakhulu kunalezo ezikumaphuzu 1 no-6, okubonisa ukuthi ukwakheka kwendawo enesici akulingani futhi kukhona ukungcola okungaphezulu okuhilelekile;

I-4.5 Yenza ukuhlaziywa kwengxenye kumaphuzu we-2 no-3 futhi yathola ukuthi izingxenye ziqukethe isici se-Ca, okubonisa ukuthi i-talcum powder kungenzeka ukuthi ihileleke ebusweni benduku ye-aluminium ngesikhathi senqubo yokukhipha.

5 Isifinyezo

Ngemuva kokuhlaziywa okungenhla, kungase kubonakale ukuthi ngenxa yokuba khona kokuhlukaniswa, i-ejenti yokuhlanza, i-talcum powder kanye ne-slag inclusions ebusweni benduku ye-aluminium, ukubunjwa akulingani, futhi isikhumba sigoqwe emgodini wesikhunta ngesikhathi sokukhishwa, okwenza kube nesici sokucwenga ekhanda. Ngokunciphisa izinga lokushisa lenduku yokuphonsa kanye nokuqina kokuqina okusele, izinkinga zokucwecwa nokuchotshozwa zingancishiswa noma zixazululwe; isilinganiso esiphumelela kakhulu ukwengeza umshini wokucwecwa wokucwecwa nokukhipha.

Ihlelwe nguMay Jiang evela kwaMAT Aluminium

Isikhathi sokuthumela: Jun-12-2024