1. Izici ze-aluminium ne-aluminium ingxubevange ye-alloy ekhethekile yokunemba okukhethekile

Lolu hlobo lomkhiqizo lunomumo okhethekile, ukujiya kodonga oluncane, isisindo seyunithi ekhanyayo, kanye nezidingo eziqinile zokubekezelelana. Imikhiqizo enjalo ngokuvamile ibizwa ngokuthi amaphrofayili e-aluminium alloy precision (noma ultra-precision) (amapayipi), futhi ubuchwepheshe bokukhiqiza imikhiqizo enjalo bubizwa ngokuthi ukunemba. (noma ukunemba okuphezulu) i-extrusion.

Izici eziyinhloko zokunemba okukhethekile kwe-aluminium alloy (noma ukunemba okuphezulu) yilezi:

(1)Kunezinhlobonhlobo eziningi, amaqoqo amancane, futhi iningi lazo liyizinto ezisetshenziswayo zokukhipha izinjongo ezikhethekile, ezisetshenziswa cishe kuzo zonke izigaba zokuphila nazo zonke izici zokuphila kwabantu, okuhlanganisa yonke imikhiqizo yokukhishwa, njengamapayipi, imigoqo, amaphrofayili nezintambo, ezihlanganisa ingxubevange ehlukahlukene kanye nesimo. Ngenxa yezingxenye zayo ezincane eziphambanayo, ukujiya kodonga oluncane, isisindo esilula, namaqoqo amancane, ngokuvamile akulula ukuhlela ukukhiqizwa.

(2) Amajamo ayinkimbinkimbi namakhontolo akhethekile, iningi lawo anomumo, ayisicaba, abanzi, anamaphiko, anamazinyo, amaphrofayili anezimbobo noma amapayipi. Indawo engaphezulu ngevolumu yeyunithi inkulu, futhi ubuchwepheshe bokukhiqiza bunzima.

(3) Ukusetshenziswa okubanzi, ukusebenza okukhethekile kanye nezidingo zokusebenza. Ukuze kuhlangatshezwane nezidingo zokusetshenziswa komkhiqizo, izifunda eziningi ze-alloy zikhethiwe, ezimboza cishe wonke ama-alloys kusukela ku-1××× kuya ku-8××× uchungechunge kanye nenqwaba yezifunda zokwelashwa, ezinokuqukethwe okuphezulu kobuchwepheshe.

(4) Ukubukeka okuhle nokujiya kodonga oluncane, ngokuvamile olungaphansi kuka-0.5mm, abanye baze bafinyelele cishe ku-0.1mm, isisindo imitha ngalinye singamagremu ambalwa kuphela amashumi amagremu, kodwa ubude bungafinyelela amamitha amaningana, noma ngisho namakhulu amamitha.

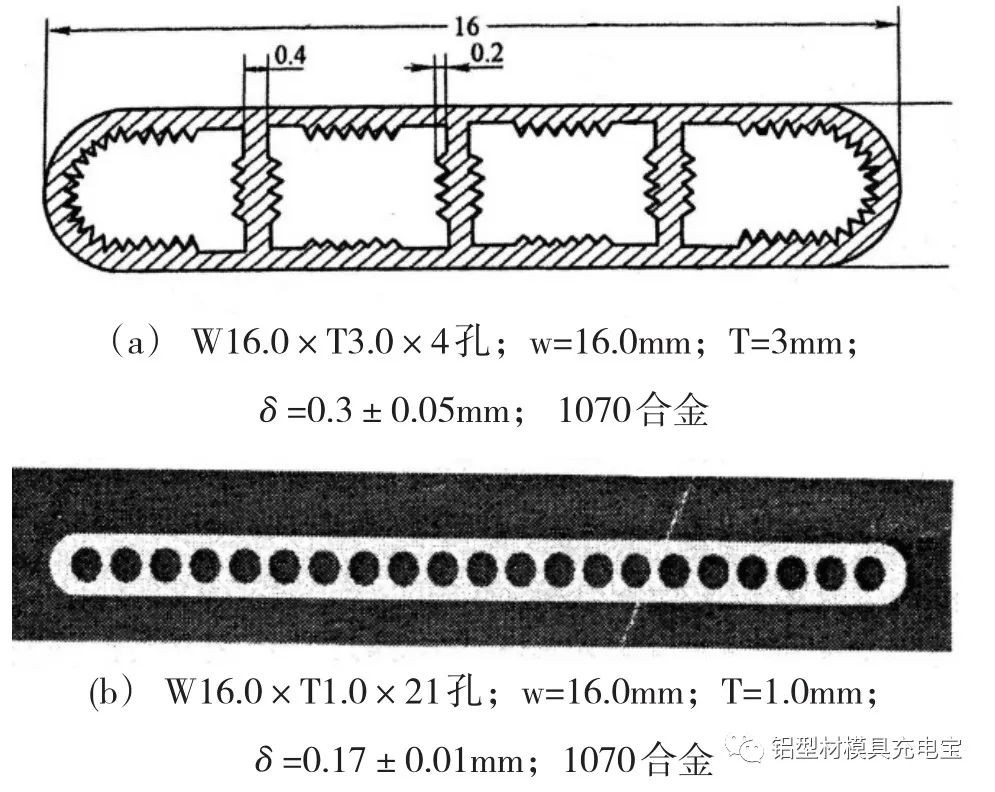

5) Ukunemba kobukhulu kanye nezidingo zokubekezelela ijometri zesigaba ziqinile kakhulu. Ngokuvamile, ukubekezelelwa kwamaphrofayili amancane we-aluminium alloy anemba aqine ngokuphindwe kabili njengokubekezelelwa kwebanga elikhethekile kumazinga we-JIS, GB, kanye ne-ASTM. Ukubekezelela ukuqina kodonga kwamaphrofayili engxubevange ye-aluminium enembayo evamile kuyadingeka ukuthi kube phakathi kuka-±0.04mm no-0.07mm, kuyilapho ukubekezelela usayizi wesigaba wamaphrofayela engxube ye-aluminium enembe kakhulu kungase kube phezulu ngokufika ku-±0.01mm. Isibonelo, isisindo sephrofayela enembayo ye-aluminium esetshenziselwa i-potentiometer ngu-30g/m, futhi ububanzi bokubekezelela bosayizi wesigaba ngu-±0.07mm. Ukubekezelela usayizi wezingxenye eziphambanayo wamaphrofayili e-aluminium anembayo kuma-looms ngu-±0.04mm, ukuchezuka kwe-engeli kungaphansi kuka-0.5°, kanti idigri yokugoba ngu-0.83×L. Esinye isibonelo ishubhu eliyisicaba elinembe kakhulu lezimoto, elinobubanzi obungu-20mm, ubude obungu-1.7mm, ukujiya kodonga okungu-0.17±0.01mm, nezimbobo ezingu-24, okungamaphrofayili ealloy e-aluminium anembile kakhulu.

(6) Inokuqukethwe okuphezulu kwezobuchwepheshe futhi kunzima kakhulu ukukhiqiza, futhi inezidingo ezikhethekile zemishini ye-extrusion, amathuluzi, amabhilidi kanye nezinqubo zokukhiqiza. Umdwebo 1 uyisibonelo sesigaba samaphrofayili amancane we-aluminium alloy anembayo.

2. Ukwahlukaniswa kwe-aluminium alloy okukhethekile okunemba okukhethekile kwe-extrusion

Ukunemba noma ukunemba okuphezulu kwe-aluminium alloy extrusions asetshenziswa kabanzi kumathuluzi kagesi, izinto zokuxhumana kanye nesayensi esezingeni eliphezulu, ukuvikela izwe kanye nemboni yezempi, amathuluzi emishini enembile, imishini yamanje ebuthakathaka, i-aerospace, imboni yenuzi, amandla namandla, imikhumbi-ngwenya nemikhumbi, izimoto namathuluzi ezokuthutha , imishini yezokwelapha, amathuluzi ehadiwe, ukukhanyisa, izithombe nezinto zikagesi. Ngokuvamile, ukunemba noma ukunemba kwe-aluminium alloy extrusions kungahlukaniswa ngezigaba ezimbili ngokuya nezici zabo zokubukeka: isigaba sokuqala amaphrofayili anobukhulu obuncane. Lolu hlobo lwephrofayili lubizwa nangokuthi iphrofayili ye-ultra-small noma umumo omncane. Ubukhulu bayo bubonke ngokuvamile bungamamilimitha ambalwa kuphela, ubukhulu bodonga obuncane bungaphansi kuka-0.5mm, kanti isisindo seyunithi singamagremu amaningana kuya kumashumi amagremu imitha ngayinye. Ngenxa yobukhulu bazo obuncane, ukubekezelelana okuqinile kuvame ukudingeka kubo. Isibonelo, ukubekezelelwa kobukhulu besigaba esiphambene kungaphansi kuka-±0.05mm. Ngaphezu kwalokho, izidingo zokuqina kanye ne-torsion yemikhiqizo ekhishwe futhi ziqinile kakhulu.

Olunye uhlobo amaphrofayili angewona amancane kakhulu ngosayizi wezingxenye eziphambanayo kodwa adinga ukubekezelela okuqinile kobukhulu, noma amaphrofayili anomumo oyinkimbinkimbi wesigaba esiphambanayo nogqinsi oluncane lodonga nakuba ubukhulu besigaba esiphambene bukhulu. Umfanekiso 2 ubonisa ishubhu elimise okukhethekile (i-aluminium ehlanzekile yezimboni) ekhishwe inkampani yase-Japan emshinini wokunyathelisa ovundlile we-hydraulic ongu-16.3MN onomhlukanisi okhethekile wokufa we-condenser yemoto ye-air-conditioning. Ubunzima bokwakhiwa kwe-extrusion yalolu hlobo lwephrofayili abukho ngaphansi kohlobo lwangaphambili lwephrofayili encanyana kakhulu. Amaphrofayili anwetshiwe anosayizi wesigaba esikhulu kanye nezidingo eziqinile zokubekezelelana azidingi nje kuphela ubuchwepheshe bokuklama isikhunta esithuthukisiwe, kodwa futhi zidinga ubuchwepheshe obuqinile bokuphatha kuyo yonke inqubo yokukhiqiza kusukela ekungenalutho kuya kumkhiqizo ophelile.

Kusukela ekuqaleni kwawo-1980, ngenxa yokusetshenziswa okungokoqobo kobuchwepheshe be-Conform continuous extrusion kanye nokuthuthukiswa kobuchwepheshe bezimboni, ukukhishwa kwamaphrofayili amancane namancane kakhulu kuye kwathuthuka ngokushesha. Kodwa-ke, ngenxa yezizathu ezihlukahlukene ezifana nokulinganiselwa kwemishini, izidingo zekhwalithi yomkhiqizo, kanye nentuthuko kubuchwepheshe bokukhipha, ukukhiqizwa kwamaphrofayili amancane kumpahla evamile yokukhipha impahla kusazoba nengxenye enkulu. Umfanekiso wesi-2 ubonisa amaphrofayili anembayo we-extrusion yokufa okuhlukaniswa okujwayelekile. Ukuphila kwesikhunta (ikakhulukazi amandla nokugqoka ukumelana kwebhuloho le-shunt kanye ne-mold core) kanye nokugeleza kwezinto ezibonakalayo ngesikhathi se-extrusion kuba yizici eziyinhloko ezithinta ukukhiqizwa kwayo. Lokhu kungenxa yokuthi lapho ukhipha iphrofayili, ubukhulu be-mold core buncane futhi ukuma kuyinkimbinkimbi, futhi amandla nokumelana nokugqoka kuyizici ezibalulekile ezithinta impilo yesikhunta, impilo yesikhunta ithinta ngqo izindleko zokukhiqiza. Ngakolunye uhlangothi, amaphrofayili amaningi anembayo anezindonga ezincane nezimo eziyinkimbinkimbi, futhi ukuhamba kwezinto ngesikhathi senqubo ye-extrusion kuthinta ngokuqondile ukuma nokunemba kobukhulu bamaphrofayili.

Ukuze uvimbele ifilimu ye-oxide namafutha ebusweni be-billet ukuthi ingagelezi emkhiqizweni futhi iqinisekise ikhwalithi efanayo kanye nekhwalithi ethembekile yomkhiqizo, i-billet evuthayo ekushiseni okubekiwe ingahlungwa ngaphambi kokukhipha (okubizwa ngokuthi i-hot peeling), bese ifakwa ngokushesha emgqonyeni we-extrusion we-extrusion. Ngesikhathi esifanayo, i-gasket ekhishwe kufanele igcinwe ihlanzekile ukuvimbela amafutha nokungcola ekunamatheleni ku-gasket ngesikhathi senqubo yokukhipha ingcindezi eyengeziwe ngemva kokukhipha okukodwa nokufaka i-gasket ku-extrusion elandelayo.

Ngokuvumelana nesigaba sokunemba nokwakheka nokubekezelelana kwesikhundla, ukunemba okukhethekile kwe-aluminium alloy extrusion kungahlukaniswa ngamaphrofayili akhethekile we-aluminium alloy anembile kanye namaphrofayili amancane (amancanyana) ane-ultra-high precision aluminium alloy. Ngokuvamile, ukunemba kwayo kudlula izinga likazwelonke (elifana ne-GB, i-JIS, i-ASTM, njll.) ukunemba okuphezulu kakhulu kubizwa ngokuthi amaphrofayli akhethekile we-aluminium alloy, isibonelo, ukubekezelelana kwe-dimensional kungaphezu kuka-±0.1mm, ukubekezelelana kodonga lwendawo ephukile kungaphakathi kwephrofayili engu-± 0.05mm ~ ± 0.03mm.

Uma ukunemba kwayo kungaphezu kokuphindwe kabili kwesilinganiso sikazwelonke sokunemba okuphezulu kakhulu, kubizwa ngephrofayili yealloy yealloy encane (encane) ephezulu kakhulu, njengokubekezelela komumo okungu-±0.09mm, ukubekezelela ukushuba kodonga okungu-±0.03mm ~ ± ±0.01mm kuphrofayela noma ipayipi elincane (elincane).

3. Amathemba okuthuthukiswa kwe-aluminium ne-aluminium ingxubevange yezinto ezikhethekile zokunemba okunembayo

Ngo-2017, ukukhiqizwa nokuthengiswa kwezinto zokucubungula i-aluminium emhlabeni kudlule i-6000kt/a, lapho ukukhiqizwa nokudayiswa kwe-aluminium ne-aluminium alloy extrusion materials kudlula u-25000kt/a, okubala ngaphezu kuka-40% wengqikithi yokukhiqiza nokudayiswa kwe-aluminium. Imigoqo ye-Aluminium extruded medium ibalelwa ku-90%, lapho amaphrofayili nemigoqo ejwayelekile kanye namaphrofayili esakhiwo somphakathi amancane naphakathi abalwe ngaphezu kuka-80% webha, amaphrofayili amakhulu naphakathi nendawo kanye namaphrofayili akhethekile nemigoqo ebalelwa ku-15% kuphela. Ipayipi lithatha cishe u-8% we-aluminium alloy extruded, kanti ipayipi elimise okukhethekile kanye ne-akhawunti ekhethekile yepayipi ithatha kuphela amaphesenti angu-20 wepayipi. Kungabonakala kulokhu okungenhla ukuthi ukukhiqizwa nokuthengiswa okukhulu kwe-aluminium ne-aluminium alloy extrusion materials futhi esetshenziswa kakhulu amaphrofayili wokwakha umphakathi amancane naphakathi, amaphrofayili ajwayelekile kanye nemigoqo namapayipi. Futhi amaphrofayili akhethekile, imigoqo kanye namapayipi alandisa kuphela mayelana ne-15%, izici eziyinhloko zemikhiqizo enjalo yilezi: ngemisebenzi ekhethekile noma ukusebenza; Kunikezelwe injongo ethile; Ukuba nosayizi omkhulu noma omncane wokucaciswa; Ngokunemba okuphezulu kakhulu kwe-dimensional noma izidingo zangaphezulu. Ngakho-ke, izinhlobonhlobo ziningi futhi i-batch incane, isidingo sokwandisa izinqubo ezikhethekile noma ukwengeza ezinye izinto ezikhethekile namathuluzi, ukukhiqiza kunzima futhi okuqukethwe kwezobuchwepheshe kuphezulu, izindleko zokukhiqiza zanda futhi inani elingeziwe liyakhula.

Ngokuthuthuka kwesayensi nobuchwepheshe kanye nokuthuthukiswa okuqhubekayo kwamazinga okuphila abantu, izidingo eziphakeme neziphakeme ziye zabekwa phambili zokukhishwa, ikhwalithi kanye nezinhlobonhlobo zemikhiqizo ye-aluminium ne-aluminium alloy extrusion, ikakhulukazi eminyakeni yamuva, ukuvela kokwenziwa komuntu siqu komkhiqizo kuye kwakhuthaza ukuthuthukiswa kwamaphrofayili akhethekile namapayipi anezici zomuntu siqu kanye nokusetshenziswa okuqondile.

Amaphrofayili anembe kakhulu asetshenziswa kakhulu kumathuluzi e-elekthronikhi, ezokuxhumana, eposini nasezintweni zokuxhumana, imishini enembayo, amathuluzi anembayo, amathuluzi amanje abuthakathaka, i-aerospace, imikhumbi-ngwenya yenuzi nemikhumbi, imboni yezimoto kanye neminye imikhakha yodonga oluncane, oluncane, usayizi wesigaba sezingxenye ezinembe kakhulu. Ngokuvamile izidingo zokubekezelelana ziqinile kakhulu, isibonelo, ukubekezelelana kosayizi wesigaba kungaphansi kuka-± 0.10mm, ukubekezelelana kodonga kungaphansi kuka-± 0.05mm. Ngaphezu kwalokho, i-flatness, ukusonteka kanye nezinye izinhlobo nokubekezelelana kwesikhundla semikhiqizo ekhishwe futhi kuqinile kakhulu. Ngaphezu kwalokho, enqubweni ye-extrusion yamaphrofayili amancane akhethekile we-aluminium alloy, imishini, isikhunta, inqubo yizidingo eziqinile kakhulu. Ngenxa yentuthuko esheshayo yemboni yesimanje, ukuzivikela kuzwelonke kanye nocwaningo lwesayensi kanye nezinye izinto ezenziwayo kanye nokuthuthukiswa kwezinga lomuntu siqu, inani, izinhlobonhlobo kanye nekhwalithi yamaphrofayili amancane ane-ultra-nemba liya ngokuya liphakeme, nakuba eminyakeni yamuva nje, liye lathuthuka futhi lakhiqiza amaphrofayli amaningi e-aluminium alloy esezingeni eliphezulu, kodwa namanje akakwazi ukuhlangabezana nezidingo ezithile zemishini yokukhiqiza yasekhaya, kukhona igebe phakathi kwemakethe yokukhiqiza. yamaphrofayili amancane e-aluminium alloy ane-ultra-precision kanye nezinga elithuthukile lamazwe ngamazwe, elingakwazi ukuhlangabezana nesidingo semakethe yasekhaya neyangaphandle futhi kufanele ibanjwe.

4. Isiphetho

I-Aluminium ne-aluminium ingxubevange ye-alloy ekhethekile yokunemba okukhethekile (amaphrofayili namapayipi) iwuhlobo lokuma okuyinkimbinkimbi, ukushuba kodonga oluncane, ukubekezelelana kobukhulu nokuma kanye nezidingo zokunemba kwesikhundla zidinga kakhulu, okuqukethwe okuphezulu kwezobuchwepheshe, ukukhiqizwa okunzima kwezinto eziphezulu, ezinhle, umnotho wezwe kanye nokuvikela kazwelonke izinto ezibalulekile ezibalulekile, uhla olubanzi kakhulu lokusetshenziswa, othembisayo ukuthuthukiswa kwezinto ezibonakalayo. Ukukhiqizwa kwalo mkhiqizo kunezidingo ezikhethekile ze-billet, i-tooling kanye nemishini ye-extrusion kanye nenqubo ye-extrusion, futhi uchungechunge lwezinkinga ezibalulekile zobuchwepheshe kufanele zixazululwe ukuze kutholwe imikhiqizo emihle kakhulu ngamaqoqo.

Ihlelwe nguMay Jiang evela kwaMAT Aluminium

Isikhathi sokuthumela: Apr-07-2024