I-anodizing inqubo esetshenziselwa ukwakha ifilimu ye-aluminium oxide ebusweni bemikhiqizo ye-aluminium noma ye-aluminium alloy. Kuhilela ukubeka umkhiqizo we-aluminium noma i-aluminium alloy njenge-anode esixazululweni se-electrolyte kanye nokusebenzisa amandla kagesi ukwenza ifilimu ye-aluminium oxide. I-anodizing ithuthukisa ukumelana nokugqwala, ukumelana nokugqoka, kanye nezakhiwo zokuhlobisa zamaphrofayili e-aluminium. Ngesikhathi senqubo ye-anodizing yamaphrofayili e-aluminium, izici ezimbalwa ezijwayelekile zokukhubazeka zingenzeka. Masiqonde ikakhulukazi izimbangela zokukhubazeka okubonakalayo. Ukugqwala kwempahla, ukungcoliswa kokugeza, ukuna kwezigaba zesibili zengxubevange, noma imiphumela ye-galvanic konke kungaholela ekulimaleni okubonakalayo. Zichazwa kanje:

1.I-Acid noma i-alkali etching

Ngaphambi kokugcotshwa, i-aluminiyamu ingagqwala yi-asidi noma uketshezi lwe-alkaline, noma ithintwe umusi we-asidi noma we-alkaline, okuholela ekubeni kube namachashaza amhlophe endaweni. Uma ukugqwala kubi kakhulu, kungakheka izindawo zokubhoboza ezinkulu. Kunzima ukunquma ngeso lenyama ukuthi ukugqwala kubangelwa i-asidi noma i-alkali, kodwa kungahlukaniswa kalula ngokubheka ingxenye enqamulayo yendawo egqwalile ngaphansi kwesibonakhulu. Uma iphansi lomgodi liyindilinga futhi lingenakho ukugqwala kwe-intergranular, kubangelwa ukucwiliswa kwe-alkali. Uma okuphansi kungavamile futhi kuhambisana nokugqwala kwe-intergranular, enemigodi ejulile, kubangelwa ukucwiliswa kwe-asidi. Ukugcinwa nokuphathwa ngendlela engafanele efektri nakho kungaholela kulolu hlobo lokugqwala. Imfucumfucu ye-asidi evela ejensi yokupholisha amakhemikhali noma enye intuthu ene-asidi, kanye nama-organic degreasers ane-chlorinated, iyimithombo yokushumeka kwe-asidi. Ukufakwa kwe-alkali okuvamile kubangelwa ukusakazeka nokusaphazwa kodaka, umlotha kasimende, noketshezi oluwasha lwe-alkali. Uma imbangela isinqunyiwe, ukuqinisa ukuphathwa kwezinqubo ezihlukahlukene efektri kungaxazulula inkinga.

2.Ukugqwala kwe-atmospheric

Amaphrofayili e-Aluminium achayeke emoyeni oswakeme angase athuthuke amachashaza amhlophe, avame ukuhleleka ngobude eduze kwemigqa yokukhunta. Ukugqwala kwe-atmospheric ngokuvamile akubi kakhulu njenge-acid noma i-alkali etching futhi kungasuswa ngezindlela zemishini noma ukugeza nge-alkali. Ukugqwala kwe-atmospheric ngokuvamile akukona okwendawo futhi kuvame ukwenzeka ezindaweni ezithile, njengezindawo zokushisa eziphansi lapho umhwamuko wamanzi ujiya kalula noma ezindaweni ezingaphezulu. Lapho ukugqwala komkhathi kubi kakhulu, ingxenye ephambanayo yamachashaza omgodi ibonakala njengamakhowe ahlanekezelwe. Kulokhu, ukugeza kwe-alkali akukwazi ukuqeda izindawo zokubhoboza futhi kungase kukhulise. Uma ukugqwala kwe-atmospheric kunqunywa, izimo zokugcina efektri kufanele zihlolwe. Izinto ze-aluminium akufanele zigcinwe ezindaweni ezinokushisa okuphansi kakhulu ukuze kuvinjelwe ukufiphala komhwamuko wamanzi. Indawo yokugcina kufanele yome, futhi izinga lokushisa kufanele lifane ngangokunokwenzeka.

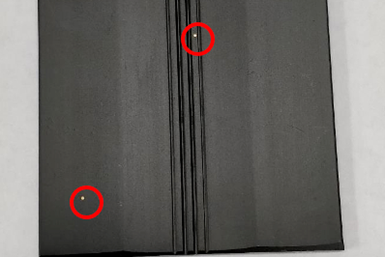

3.Ukugqwala kwephepha (amabala amanzi)

Uma iphepha noma amakhadibhodi kubekwa phakathi kwezinto ze-aluminium noma ezisetshenziselwa ukupakisha, kuvimbela ukuhuzuka. Kodwa-ke, uma iphepha liba manzi, amabala okugqwala avela ebusweni be-aluminium. Lapho kusetshenziswa amakhadibhodi kathayela, imigqa evamile yamabala okugqwala ibonakala ezindaweni lapho kuxhunywana khona nebhodi likathayela. Nakuba ngezinye izikhathi ukukhubazeka kungase kubonakale ngokuqondile endaweni ye-aluminium, kuvame ukuvela kakhulu ngemva kokugeza nge-alkaline kanye ne-anodizing. Lawa machashaza ngokuvamile ajulile futhi kunzima ukuwasusa ngokusebenzisa imishini noma ukuwasha nge-alkaline. Ukugqwala kwephepha (ibhodi) kubangelwa ama-ion e-asidi, ikakhulukazi i-SO42- ne-Cl-, akhona ephepheni. Ngakho-ke, ukusebenzisa iphepha (ibhodi) ngaphandle kwama-chloride nama-sulfate nokugwema ukungena kwamanzi kuyindlela ephumelelayo yokuvimbela ukugqwala kwephepha (ibhodi).

4.Ukugqwala kwamanzi okuhlanza (okubuye kwaziwe ngokuthi i-snowflake corrosion)

Ngemva kokugeza okune-alkaline, ukupholishwa ngamakhemikhali, noma ukucotshwa kwe-sulfuric acid, uma amanzi okugeza equkethe ukungcola, kungase kubangele amabala amise okwenkanyezi noma akhazimulayo phezulu. Ukugqwala akujulile. Lolu hlobo lokugqwala lwenzeka lapho amanzi okuhlanza engcoliswe kakhulu noma lapho izinga lokugeleza lokuchichima lokuhlanzwa liphansi. Ifana namakristalu amise okweqhwa ngokubukeka, yingakho igama elithi "i-snowflake corrosion." Isizathu ukusabela phakathi kokungcola kwe-zinc ku-aluminium kanye ne-SO42- ne-Cl- emanzini okuhlanza. Uma ukufakwa kwe-tank kungalungile, imiphumela ye-galvanic ingabhebhethekisa lesi sici. Ngokusho kwemithombo yangaphandle, lapho okuqukethwe kwe-Zn ku-aluminium alloy kukhulu kune-0.015%, i-Cl- emanzini okuhlanza iphakeme kune-15 ppm, lolu hlobo lokugqwala lungenzeka. Ukusebenzisa i-nitric acid ekukhetheni noma ukwengeza u-0.1% HNO3 emanzini okuhlanza kungaqeda.

5.Ukugqwala kwe-chloride

Ukuba khona kwenani elincane le-chloride okugeza okune-sulfuric acid anodizing nakho kungaholela ekugqwaleni komgodi. Ukubukeka kwesici imigodi emnyama emise okwenkanyezi emnyama, egxile kakhulu emaphethelweni nasemakhoneni ocezu lokusebenza noma kwezinye izindawo ezinokuminyana okuphezulu kwamanje. Izindawo zemigodi azinayo ifilimu ye-anodized, futhi ukushuba kwefilimu ezindaweni ezisele "ezivamile" kuphansi kunevelu elindelekile. Usawoti omningi emanzini kampompi uwumthombo omkhulu wokungcoliseka ebhavini.

6.Galvanic corrosion

Ethangini elinamandla (umbala we-anodizing noma we-electrolytic), imiphumela ye-galvanic phakathi kwendawo yokusebenza nethangi (ithangi lensimbi), noma imithelela yemisinga elahlekile ethangini elinganikeziwe amandla (ukuhlanzwa noma ukuvala), kungabangela noma kubhebhethekise ukugqwala komgodi.

Ihlelwe nguMay Jiang evela kwaMAT Aluminium

Isikhathi sokuthumela: Dec-15-2023