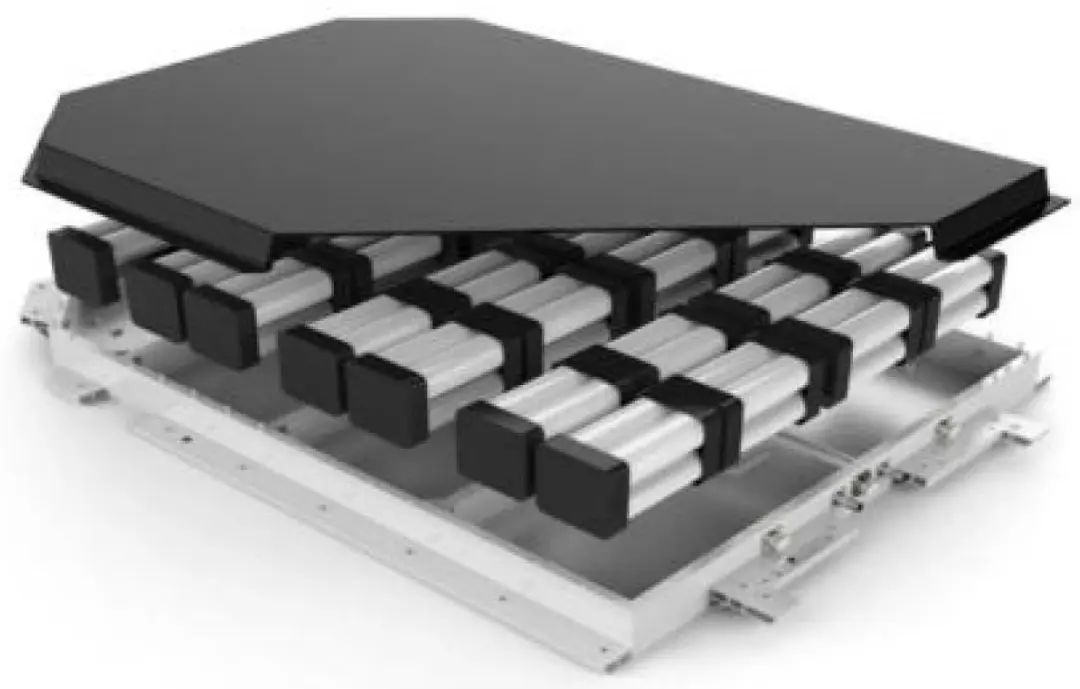

Ibhethri liyingxenye eyinhloko yemoto kagesi, futhi ukusebenza kwayo kunquma izinkomba zobuchwepheshe ezifana nempilo yebhethri, ukusetshenziswa kwamandla, nempilo yesevisi yemoto kagesi. Ithreyi yebhethri kumojuli yebhethri iyingxenye eyinhloko eyenza imisebenzi yokuthwala, ukuvikela, nokupholisa. Iphakethe lebhethri le-modular lihlelwe kuthreyi yebhethri, ligxilwe ku-chassis yemoto ngethreyi yebhethri, njengoba kuboniswe ku-Figure 1. Njengoba ifakwe ngaphansi komzimba wemoto futhi indawo yokusebenza inzima, i-tray yebhethri idinga ukuba nomsebenzi wokuvimbela umthelela wetshe kanye nokubhoboza ukuvimbela imoduli yebhethri ukuthi ingalimazi. Ithreyi yebhethri iyingxenye ebalulekile yesakhiwo sokuphepha sezimoto zikagesi. Okulandelayo kwethula inqubo yokwakha kanye nokwakheka kwesikhunta samathileyi ebhethri e-aluminium alloy ezimotweni zikagesi.

Umfanekiso 1 (Ithreyi yebhethri ye-aluminium alloy)

1 Ukuhlaziywa kwenqubo kanye nokwakhiwa kwesikhunta

1.1 Ukuhlaziywa kokusakaza

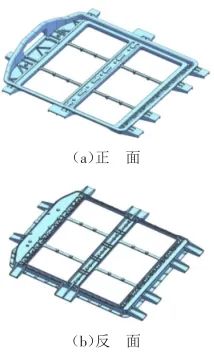

Ithreyi yebhethri ye-aluminium alloy yezimoto zikagesi iboniswa kuMfanekiso 2. Ubukhulu obuphelele buyi-1106mm×1029mm×136mm, ubukhulu bodonga oluyisisekelo ngu-4mm, ikhwalithi yokuphonsa imayelana no-15.5kg, futhi ikhwalithi yokuphonsa ngemva kokucubungula imayelana ne-12.5kg. Impahla ingu-A356-T6, Amandla aqinile ≥ 290MPa, amandla esivuno ≥ 225MPa, ubude ≥ 6%, ubulukhuni beBrinell ≥ 75~90HBS, idinga ukuhlangabezana nokuqina komoya kanye nezidingo ze-IP67&IP69K.

Umfanekiso 2 (Ithreyi yebhethri ye-aluminium alloy)

1.2 Ukuhlaziya inqubo

I-low pressure die casting iyindlela ekhethekile yokuphonsa phakathi kokusakaza kwengcindezi nokuphonsa amandla adonsela phansi. Ayinayo nje kuphela izinzuzo zokusebenzisa isikhunta sensimbi kokubili, kodwa futhi inezici zokugcwalisa okuzinzile. I-low pressure die casting inezinzuzo zokugcwaliswa kwejubane eliphansi ukusuka phansi kuya phezulu, ukulawula isivinini kalula, umthelela omncane kanye ne-splash ye-aluminium ewuketshezi, i-oxide slag encane, ukuminyana kwezicubu eziphezulu kanye nezakhiwo eziphezulu zemishini. Ngaphansi kokucindezela okuphansi kwe-die cast, i-aluminium ewuketshezi igcwaliswa ngokushelelayo, futhi ukubunjwa kuyaqina futhi kucwebezele ngaphansi kwengcindezi, futhi ukubunjwa okunesakhiwo esiminyene esiphezulu, izakhiwo eziphakeme zemishini nokubukeka okuhle kungatholakala, okulungele ukwenza ama-castings amakhulu anezindonga ezincane.

Ngokusho kwezakhiwo zemishini ezidingekayo ekubunjweni, i-casting material i-A356, engahlangabezana nezidingo zamakhasimende ngemva kokwelashwa kwe-T6, kodwa ukuthululwa kwe-fluidity yalesi sici ngokuvamile kudinga ukulawula okunengqondo kokushisa kwesikhunta ukuze kukhiqizwe ama-castings amakhulu futhi amancane.

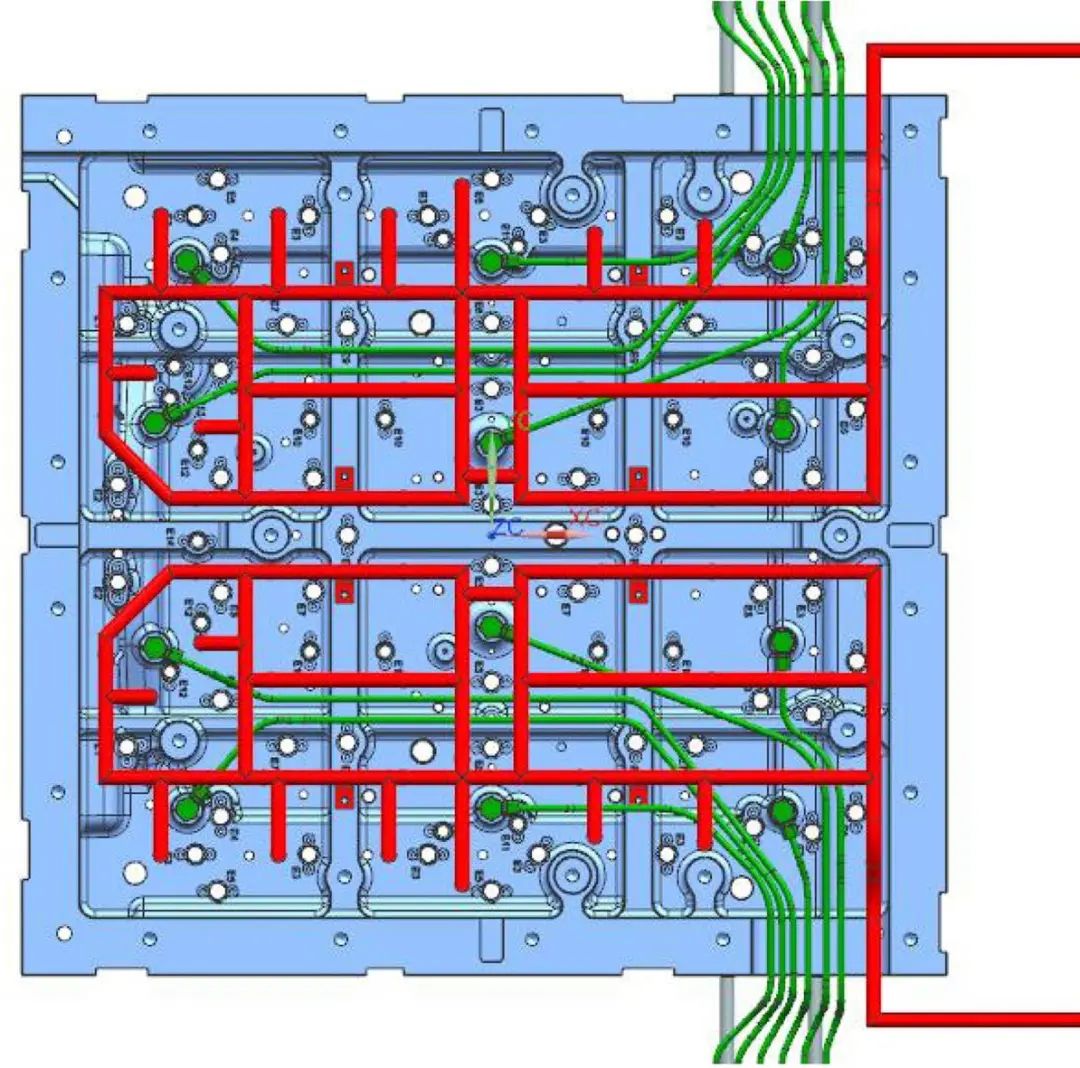

1.3 Uhlelo lokuthela

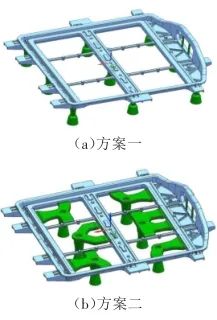

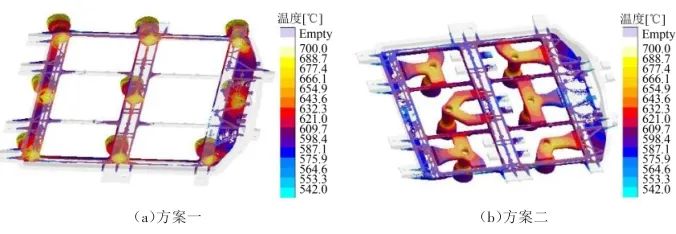

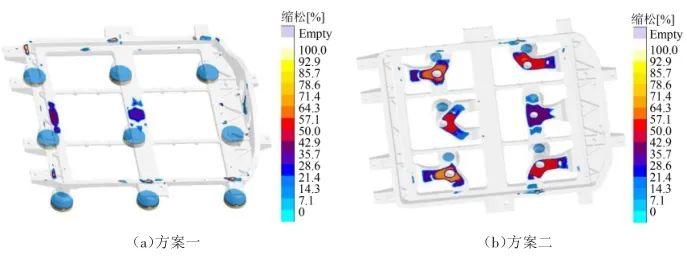

Uma kubhekwa izici ze-castings ezinkulu nezincane, amasango amaningi adinga ukuklanywa. Ngesikhathi esifanayo, ukuze kuqinisekiswe ukugcwaliswa okubushelelezi kwe-aluminium ye-liquid, iziteshi zokugcwalisa zengezwa efasiteleni, okudingeka zisuswe ngokucubungula emva kokucubungula. Izikimu zezinqubo ezimbili zesistimu yokuthela zaklanywa ekuqaleni, futhi uhlelo ngalunye lwaqhathaniswa. Njengoba kuboniswe kuMfanekiso 3, uhlelo 1 luhlela amasango angu-9 futhi lwengeza iziteshi zokudla efasiteleni; uhlelo 2 luhlela amasango angu-6 athululela ohlangothini lokubunjwa okufanele akhiwe. Ukuhlaziywa kwe-CAE sekulingisa kukhonjiswe ku-Figure 4 naku-Figure 5. Sebenzisa imiphumela yokulingisa ukuze uthuthukise isakhiwo sesikhunta, zama ukugwema umthelela omubi wokuklanywa kwesikhunta kwikhwalithi yokusakazwa, unciphise amathuba okuba nokukhubazeka kokulingisa, futhi unciphise umjikelezo wokuthuthukiswa wokubunjwa.

Umfanekiso wesi-3 (Ukuqhathaniswa kwezinhlelo ezimbili zezinqubo zokucindezela okuphansi

Umfanekiso 4 (Ukuqhathaniswa kwenkambu yezinga lokushisa ngesikhathi sokugcwalisa)

Umfanekiso 5 (Ukuqhathaniswa kokukhubazeka kwe-shrinkage porosity ngemva kokuqina)

Imiphumela yokulingisa yalezi zinhlelo ezimbili ezingenhla ibonisa ukuthi i-aluminium ewuketshezi emgodini iqhubekela phezulu cishe ngokuhambisana, okuhambisana nenkolelo-mbono yokugcwaliswa okuhambisanayo kwe-aluminium ewuketshezi iyonke, futhi izingxenye ze-shrinkage porosity ezifanisiwe zokuphonsa zixazululwa ngokuqinisa ukupholisa nezinye izindlela.

Izinzuzo zalezi zinhlelo ezimbili: Ukwahlulela kusukela ekushiseni kwe-aluminium ewuketshezi ngesikhathi sokugcwaliswa okufanisiwe, izinga lokushisa lokuphela kwe-distal of casting elakhiwe yi-scheme 1 linokufaniswa okuphezulu kune-scheme 2, okuhambisana nokugcwaliswa kwe-cavity. I-casting eyenziwe ngohlelo 2 ayinayo insalela yesango njengohlelo 1. I-shrinkage porosity ingcono kune-scheme 1.

Ukungalungi kwezinhlelo ezimbili: Ngenxa yokuthi isango lihlelwe ekubunjweni okuzokwakhiwa ohlelweni 1, kuyoba khona insalela yesango ekubunjweni, okuzokwanda cishe ngo-0.7ka uma kuqhathaniswa nokukhishwa kokuqala. kusukela ekushiseni kwe-aluminium ewuketshezi ohlelweni 2 ukugcwaliswa okufanisiwe, izinga lokushisa le-aluminium eliwuketshezi ekugcineni selivele liphansi, futhi ukulingisa kungaphansi kwesimo esihle sokushisa kwesikhunta, ngakho-ke umthamo wokugeleza we-aluminium owuketshezi ungase ungenele esimweni sangempela, futhi kuzoba nenkinga yobunzima ekubumbeni ukubunjwa.

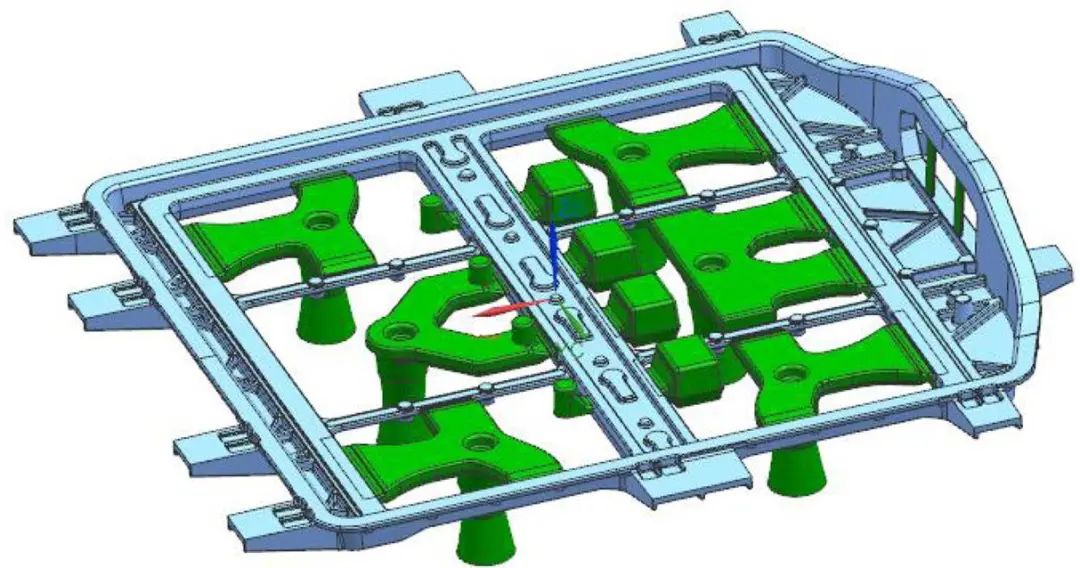

Kuhlanganiswe nokuhlaziywa kwezici ezihlukahlukene, uhlelo 2 lwakhethwa njengohlelo lokuthela. Ngokubona ukushiyeka kohlelo 2, isistimu yokuthulula kanye nesistimu yokushisa ilungiselelwe ekwakhiweni kwesikhunta. Njengoba kuboniswe kumfanekiso wesi-6, isikhuphukeli esichichimayo siyengezwa, esizuzisa ukugcwaliswa kwe-aluminium ewuketshezi futhi sinciphise noma sigweme ukuvela kweziphambeko ekubunjweni okubunjiwe.

Umfanekiso 6 (Isistimu yokuthela elungiselelwe)

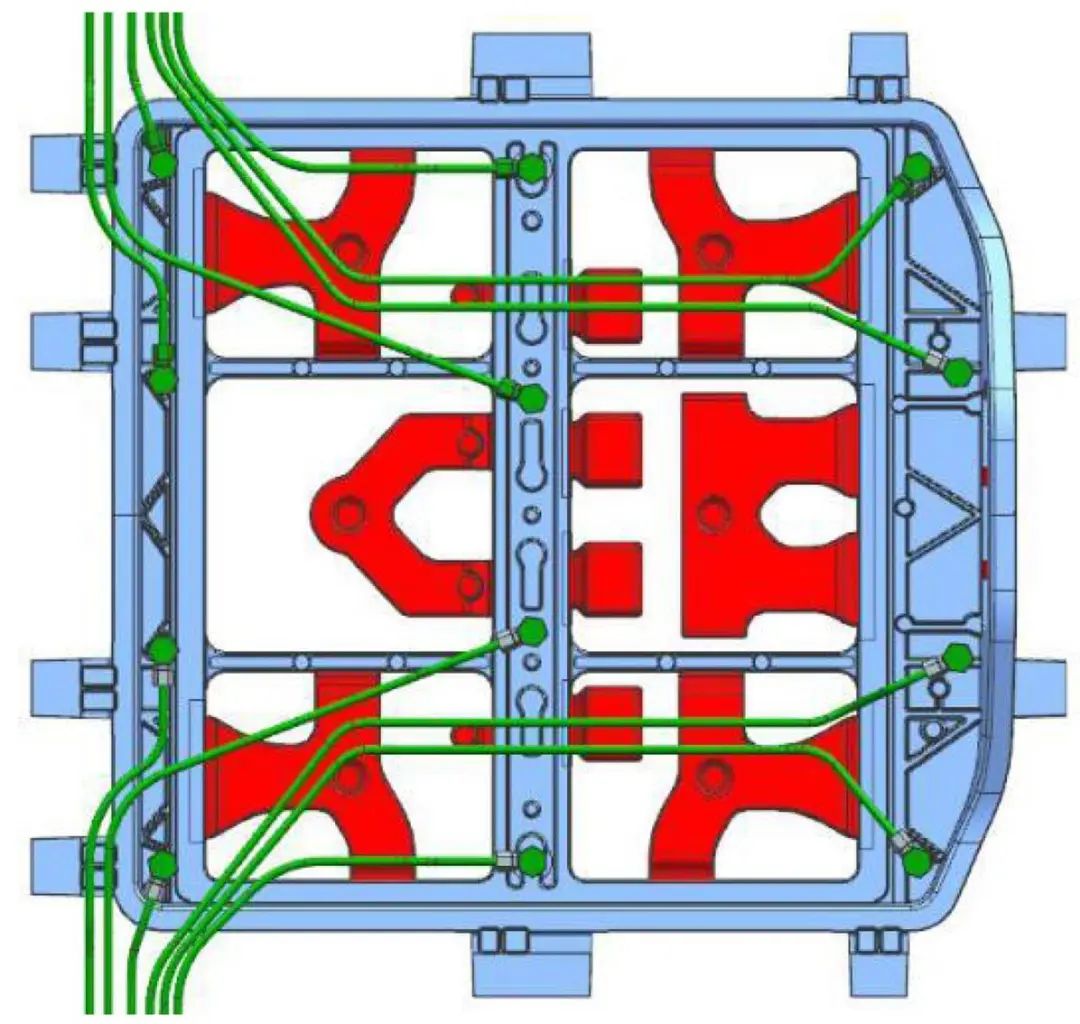

1.4 Uhlelo lokupholisa

Izingxenye ezithwala ingcindezi kanye nezindawo ezinezidingo eziphezulu zokusebenza kwemishini yokusakazwa kufanele zipholiswe kahle noma zondliwe ukuze kugwenywe ukushwabana kwe-porosity noma ukuqhekeka okushisayo. Ubukhulu obuyisisekelo bodonga bokubunjwa bungu-4mm, futhi ukuqina kuzothinteka ekushiseni kokushisa kwesikhunta ngokwaso. Ezingxenyeni zayo ezibalulekile, uhlelo lokupholisa lusethiwe, njengoba kuboniswe kuMfanekiso 7. Ngemva kokuqedwa kokugcwalisa, dlulisa amanzi ukuze aphole, futhi isikhathi esithile sokupholisa sidinga ukulungiswa endaweni yokuthulula ukuze kuqinisekiswe ukuthi ukulandelana kokuqina kwakhiwe kusukela kude nokuphela kwesango kuze kube sekugcineni kwesango, futhi isango nesikhuphukeli kuqiniswa ekugcineni ukuze kuzuzwe umphumela wokuphakelayo. Ingxenye enogqinsi olujiyile yodonga isebenzisa indlela yokwengeza ukupholisa kwamanzi kokufakwayo. Le ndlela inomphumela ongcono enqubweni yangempela yokuphonsa futhi ingagwema i-shrinkage porosity.

Umfanekiso 7 (Isistimu yokupholisa)

1.5 Isistimu yokukhipha umoya

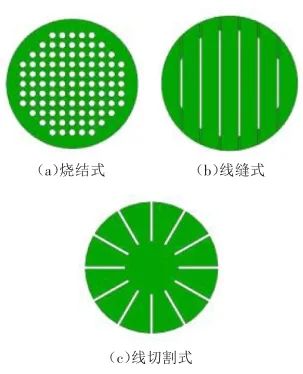

Njengoba umgodi wensimbi yokuphonsa i-low pressure die cast uvaliwe, awunakho ukungena komoya okuhle njengesikhunta sesihlabathi, futhi awuqedi ngokusebenzisa izikhuphukeli ezijwayelekile zokuphonsa amandla adonsela phansi, ukuphuma komgodi wokuphonswa kwengcindezi ephansi kuzothinta inqubo yokugcwaliswa kwe-aluminium ewuketshezi kanye nekhwalithi ye-castings. Isikhunta se-low pressure die casting singaqedwa ngokusebenzisa izikhala, i-exhaust grooves namapulaki okukhipha amandla endaweni yokuhlukanisa, induku yokusunduza njll.

Idizayini yesayizi yokukhipha ohlelweni lwe-exhaust kufanele ihambisane nokukhipha ngaphandle kokuchichima, isistimu ye-exhaust enengqondo ingavimbela ukukhishwa kusuka kumaphutha njengokugcwalisa okunganele, indawo evulekile, namandla aphansi. Indawo yokugcina yokugcwalisa ye-aluminium ewuketshezi ngesikhathi sokuthulula, njengendawo yokuphumula eseceleni kanye nesikhuphukeli sesikhunta esingaphezulu, idinga ukuhlonywa ngegesi yokukhipha. Uma kucatshangelwa iqiniso lokuthi i-aluminium ewuketshezi igeleza kalula esikhaleni sepulaki yokukhipha umoya enqubweni yangempela yokuphonswa kwengcindezi ephansi, okuholela esimweni sokuthi ipulaki yomoya ikhishwa lapho isikhunta sivulwa, izindlela ezintathu zamukelwa ngemva kwemizamo eminingana nokuthuthukiswa: Indlela yoku-1 isebenzisa ipulaki yomoya ye-powder metallurgy sintered, njengoba kukhonjisiwe kuMfanekiso 8 (ububi bokukhiqiza) yizindleko eziphezulu; Indlela yesi-2 isebenzisa ipulaki yokukhipha umoya yohlobo lomthungo enegebe elingu-0.1 mm, njengoba kukhonjisiwe kuMfanekiso 8(b), okubi ukuthi i-exhaust seam ivaleka kalula ngemva kokufafaza upende; Indlela yesi-3 isebenzisa ipulaki yokukhipha umoya esike ngocingo, igebe lingu-0.15~0.2 mm, njengoba kuboniswe kuMfanekiso 8(c). Ububi buphansi bokucubungula kanye nezindleko eziphezulu zokukhiqiza. Ama-plugs exhaust ahlukene adinga ukukhethwa ngokuya ngendawo yangempela yokusakaza. Imvamisa, amapulagi e-sintered ne-wire-cut vent asetshenziselwa umgodi wokuphonsa, futhi uhlobo lomthungo lusetshenziselwa ikhanda eliyinhloko lesihlabathi.

Umfanekiso 8 (izinhlobo ezi-3 zamapulaki okukhipha umoya afanele ukufakwa komfutho ophansi)

1.6 Uhlelo lokushisisa

Ukulingisa kukhulu ngosayizi futhi mncane ngokuqina odongeni. Ekuhlaziyweni kokugeleza kwesikhunta, izinga lokugeleza kwe-aluminium ewuketshezi ekupheleni kokugcwalisa ayanele. Isizathu siwukuthi i-aluminium ewuketshezi yinde kakhulu ukugeleza, izinga lokushisa liyehla, futhi i-aluminium ewuketshezi iqina kusengaphambili futhi ilahlekelwa amandla ayo okugeleza, ukuvala okubandayo noma ukuthululwa okwanele kwenzeka, isikhuphukeli sefa eliphezulu ngeke sikwazi ukufeza umphumela wokondla. Ngokusekelwe kulezi zinkinga, ngaphandle kokushintsha ukushuba kodonga kanye nokuma kokubunjwa, ukwandisa izinga lokushisa kwe-aluminium ewuketshezi kanye nezinga lokushisa lesikhunta, uthuthukise uketshezi lwe-aluminium ewuketshezi, futhi uxazulule inkinga yokuvala okubandayo noma ukuthululwa okunganele. Kodwa-ke, izinga lokushisa eleqile le-aluminium eliwuketshezi kanye nezinga lokushisa lesikhunta lizokhiqiza ukuhlangana okusha okushisayo noma ukushwabana kwe-porosity, okuholela emigodini eminingi yendiza ngemva kokucubungula. Ngakho-ke, kuyadingeka ukukhetha izinga lokushisa elifanele le-aluminium ewuketshezi kanye nezinga lokushisa elifanele lesikhunta. Ngokusho kokuhlangenwe nakho, izinga lokushisa le-aluminium ewuketshezi lilawulwa cishe ku-720 ℃, futhi izinga lokushisa lesikhunta lilawulwa ku-320 ~ 350 ℃.

Uma kubhekwa umthamo omkhulu, ubukhulu bodonga oluncane kanye nokuphakama okuphansi kokubunjwa, isistimu yokushisa ifakwe engxenyeni engenhla yesikhunta. Njengoba kuboniswe kuMfanekiso 9, isiqondiso selangabi sibheke phansi kanye nohlangothi lwesikhunta ukushisa indiza engezansi kanye nohlangothi lokubunjwa. Ngokwesimo sokuthulula esizeni, lungisa isikhathi sokushisa nelangabi, lawula izinga lokushisa lengxenye engaphezulu yesikhunta ku-320 ~ 350 ℃, qinisekisa uketshezi lwe-aluminium ewuketshezi phakathi kwebanga elifanele, futhi wenze i-aluminium ewuketshezi igcwalise umgodi nesikhuphukeli. Ekusetshenzisweni kwangempela, uhlelo lokushisa lungaqinisekisa ngokuphumelelayo uketshezi lwe-aluminium ewuketshezi.

Umfanekiso 9 (Isistimu yokushisisa)

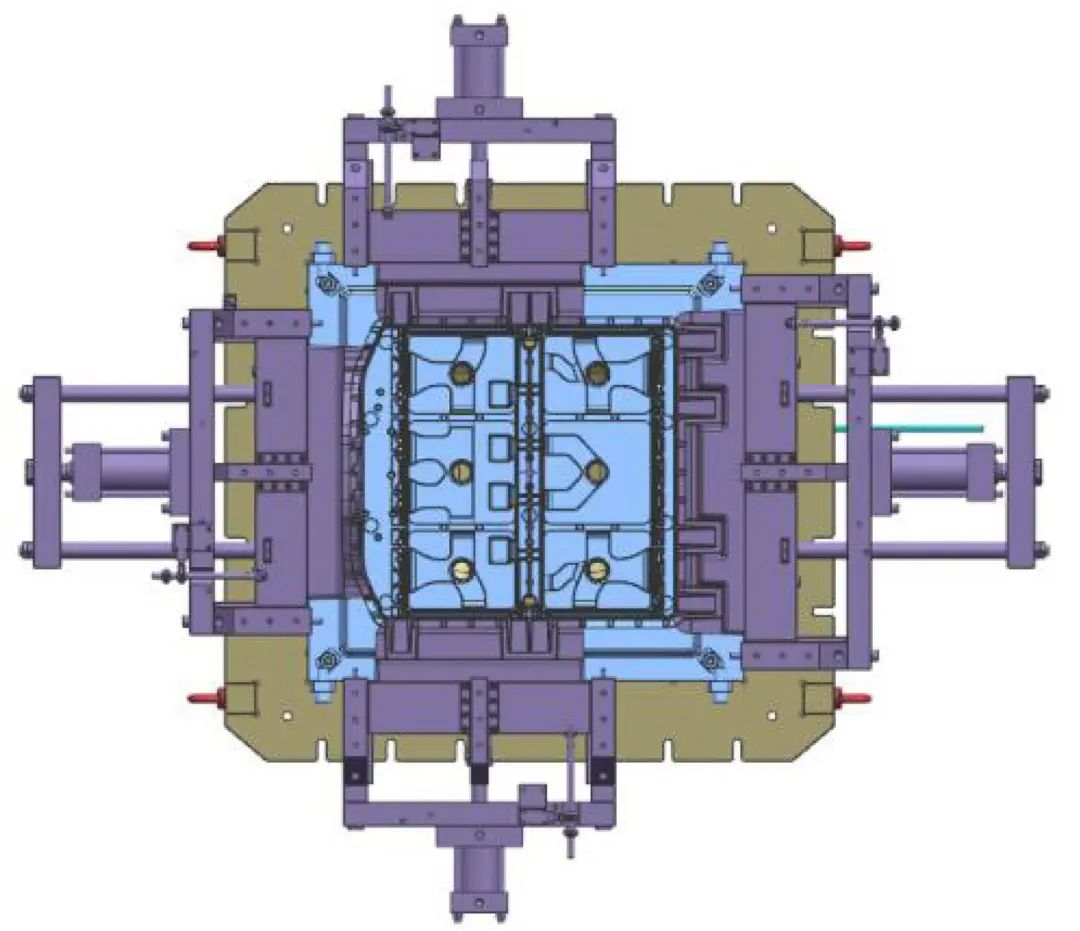

2. Isakhiwo sesikhunta kanye nesimiso sokusebenza

Ngokusho kwenqubo yokukhipha ingcindezi ephansi, ehlanganiswe nezici zokubunjwa kanye nesakhiwo semishini, ukuze kuqinisekiswe ukuthi ukubunjwa okwakhiwa kuhlala kusikhunta esiphezulu, izakhiwo zangaphambili, ezingemuva, kwesokunxele nakwesokudla ze-core-donsa zenzelwe isikhunta esiphezulu. Ngemva kokuba ukubunjwa kwakhiwe futhi kuqiniswe, isikhunta esiphezulu nesiphansi siyavulwa kuqala, bese sidonsa umongo ngezindlela ezi-4, futhi ekugcineni ipuleti eliphezulu lesikhunta esingaphezulu liphusha ukubunjwa okwenziwe. Isakhiwo sesikhunta siboniswe kuMfanekiso 10.

Umfanekiso 10 (Isakhiwo sesikhunta)

Ihlelwe nguMay Jiang evela kwaMAT Aluminium

Isikhathi sokuthumela: May-11-2023