Isikhathi sokubamba samaphrofayili e-aluminium extruded ikakhulukazi sinqunywa izinga lesisombululo esiqinile sesigaba esiqinisiwe. Izinga lesisombululo esiqinile sesigaba esiqinisiwe sihlobene nokushisa kokushisa okucishayo, isimo se-alloy, isimo, usayizi wesigaba sephrofayili ye-aluminium, izimo zokushisa, okuphakathi kanye nenani lezici zokulayisha isithando somlilo.

Lapho izinga lokushisa elivamile lokucisha lithambekele emkhawulweni ongaphezulu, isikhathi sokubamba se-aluminium sifushane ngokufanayo; Ngemuva kokushisa okuphezulu kwe-extrusion, i-deformation degree inkulu, isikhathi sokubamba sifushane. Kuphrofayili ye-aluminium yangaphambilini, ngenxa yokuthi isigaba sokuqinisa sincipha kancane futhi simahhadla, izinga lokuqedwa lesigaba sokuqinisa lihamba kancane, ngakho-ke isikhathi sokubamba siside ngokufanayo.

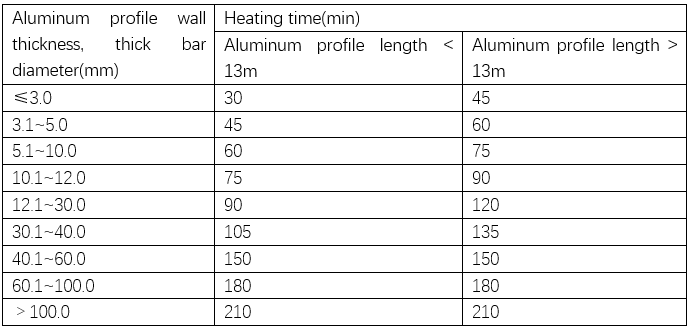

Isikhathi sokubamba samaphrofayili e-aluminium ashiswe emoyeni oshisayo sihluke kakhulu kulokho okugeza usawoti, futhi isikhathi sokushisa emanzini osawoti sifushane kakhulu. Iningi lamaphrofayili e-aluminium yezimboni noma amabha asebenzisa iziko lokucisha umoya mpo, futhi isikhathi sokubamba sibalwa lapho izinga lokushisa lensimbi noma izinga lokushisa lomlilo lifinyelela umkhawulo ophansi wezinga lokushisa lokucisha. Ithebula 1 libala izikhathi zokushisisa nokubamba zamaphrofayili e-aluminium nezinsimbi ezinosayizi abahlukene esithandweni somlilo esime mpo sokucisha umoya.

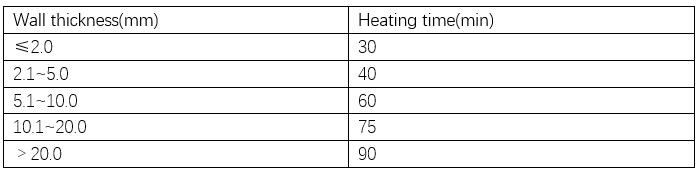

Ithebula lesi-2 libonisa isikhathi sokushisisa nokubamba samapayipi anogqinsi oluhlukene lwezindonga esithandweni sokucisha somoya esime mpo. Isikhathi sokubamba sokucima ukushisa kufanele siqinisekise ukuthi isigaba sokuqinisa sihlakazwa ngokugcwele ukuze sithole umphumela omkhulu wokuqinisa, kodwa isikhathi sokushisa akufanele sibe side kakhulu, kwezinye izimo, sizonciphisa ukusebenza kwephrofayela.

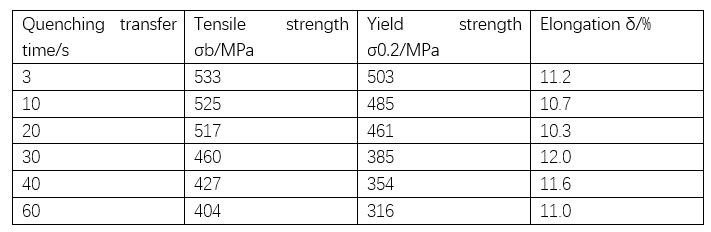

Amaphrofayili amaningi e-aluminium aphethwe ukushisa kwezimboni afana ne-2A12, 7A04 namanye amaphrofayli anamandla aphezulu awakwazi ukucinywa emoyeni njengamaphrofayili e-aluminium yezakhiwo ezifana ne-6063 alloy, okungukuthi, izinga lokupholisa elincane lingavimbela ukuna kwezigaba zokuqinisa. Zikhishwa esithandweni somlilo sokucisha, zidluliselwe ethangini lamanzi lokucisha, futhi zipholile emoyeni imizuzwana embalwa, kuzoba nemvula yezigaba zokuqinisa, ezizothinta umphumela wokuqinisa. Ithebula lesi-3 libala imiphumela yezikhathi ezihlukene zokudlulisa ze-7A04 ingxubevange ezakhiweni zemishini ngemva kokucisha.

(Ithebula 3 – 7A04 ingxubevange ecisha umphumela wokudlulisa isikhathi kuzakhiwo zemishini zamaphrofayili e-aluminium)

Ngakho-ke, isikhathi sokudlulisa sokucisha singenye yemingcele yenqubo okufanele icaciswe ekucimeni kwephrofayili ye-aluminium, okungukuthi, ukudluliswa kwamaphrofayili e-aluminium kusuka esithandweni sokucima kuya endaweni yokucisha kufanele kuqedwe phakathi nesikhathi sokudlulisa esiphezulu esishiwo, esibizwa ngokuthi isikhathi esiphezulu esivumelekile sokudlulisa noma isikhathi sokulibaziseka sokucisha. Lesi sikhathi sihlobene nokwakheka kwengxubevange, ukuma kwephrofayili, kanye nezinga lokuzenzakalelayo lokusebenza kwemishini. Uma izimo zivuma, lapho isikhathi sokudlulisa sokucisha siba sifushane, siba ngcono. Imithethonqubo yenqubo evamile: isikhathi sokudlulisa amaphrofayili amancane akufanele sidlule ama-20s, amaphrofayili amakhulu noma ama-batch acinywe i-aluminium akufanele adlule ama-40s; kumaphrofayili aqinile njenge-7A04, isikhathi sokudlulisa akufanele sidlule i-15s.

Ihlelwe nguMay Jiang evela kwaMAT Aluminium

Isikhathi sokuthumela: Oct-21-2023