Isingeniso

Ngokuthuthuka kwemboni yezimoto, imakethe yemishayo ye-aluminium alloy impact nayo ikhula ngokushesha, nakuba isencane kakhulu ngosayizi wayo. Ngokwesibikezelo se-Automotive Lightweight Technology Innovation Alliance yemakethe yaseShayina ye-aluminium alloy impact beam, ngo-2025, isidingo semakethe silinganiselwa ukuthi singamathani ayi-140,000, kanti usayizi wemakethe olindeleke ukuthi ufinyelele ku-4.8 billion RMB. Ngo-2030, isidingo semakethe kulindeleke ukuthi sibe amathani angaba ngu-220,000, ngesilinganiso semakethe esilinganiselwa ku-7.7 billion RMB, kanye nezinga lokukhula elihlanganisiwe lonyaka elicishe libe yi-13%. Umkhuba wokuthuthukiswa kokukhanya kanye nokukhula ngokushesha kwamamodeli ezimoto ezisuka maphakathi kuya kwephezulu kuyizici ezibalulekile zokushayela ekuthuthukisweni kwemishayo yethonya le-aluminium alloy e-China. Amathemba emakethe wamabhokisi okuphahlazeka kwemishayo yezimoto ayathembisa.

Njengoba izindleko zincipha futhi nobuchwepheshe buthuthuka, imishayo ye-aluminium alloy ngaphambili namabhokisi okuphahlazeka aya ngokuya anda kakhulu. Njengamanje, asetshenziswa ezimotweni zezimoto ezisezingeni eliphezulu njenge-Audi A3, Audi A4L, BMW 3 series, BMW X1, Mercedes-Benz C260, Honda CR-V, Toyota RAV4, Buick Regal, neBuick LaCrosse.

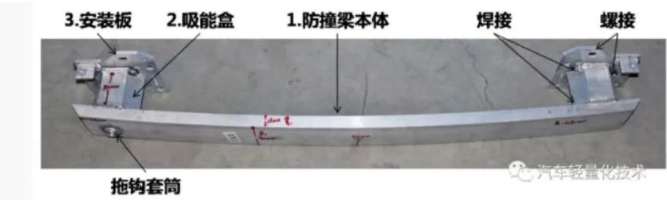

Imishayo ye-aluminium enomthelela we-alloy ikakhulukazi yakhiwe ama-cross beam, amabhokisi okuphahlazeka, ama-baseplates akhwezayo, nemikhono yehuku edonsayo, njengoba kuboniswe kuMfanekiso 1.

Umfanekiso 1: I-Aluminium Alloy Impact Beam Assembly

Ibhokisi lokuphahlazeka yibhokisi lensimbi elitholakala phakathi kwe-beam kanye nemishayo emibili yobude bemoto, esebenza njengesiqukathi esimunca amandla. La mandla asho amandla omthelela. Uma imoto ishayisana, i-beam yomthelela inezinga elithile lamandla okumunca amandla. Kodwa-ke, uma amandla edlula umthamo we-beam yomthelela, azodlulisela amandla ebhokisini lokuphahlazeka. Ibhokisi lokuphahlazeka limunca wonke amandla okuthinta futhi lizikhubaze, liqinisekise ukuthi ama-longitudinal beam ahlala engonakalisiwe.

1 Izidingo Zomkhiqizo

1.1 Ubukhulu kufanele buhambisane nezidingo zokubekezelela umdwebo, njengoba kuboniswe kuMfanekiso 2.

1.3 Izidingo Zokusebenza Kwemishini:

Amandla Okuqina: ≥215 MPa

Amandla Esivuno: ≥205 MPa

I-Elongation A50: ≥10%

1.4 Ukusebenza Kwebhokisi Lokuphahlazeka:

Eduze kwe-X-eksisi yemoto, kusetshenziswa indawo yokushayisana enkulu kunesiphambano somkhiqizo, layisha ngesivinini esingu-100 mm/min kuze kube ukuchotshozwa, ngenani lokuminyanisa elingu-70%. Ubude bokuqala bephrofayili buyi-300 mm. Lapho kuhlangana khona ubambo oluqinisayo kanye nodonga lwangaphandle, imifantu kufanele ibe ngaphansi kuka-15 mm ukuze kuthathwe njengokwamukelekayo. Kufanele kuqinisekiswe ukuthi ukuqhekeka okuvunyelwe akuphazamisi amandla okumunca amandla ephrofayili, futhi akufanele kube nokuqhekeka okubalulekile kwezinye izindawo ngemuva kokuchotshozwa.

2 Indlela Yokuthuthukisa

Ukuze ngesikhathi esifanayo kuhlangatshezwane nezidingo zokusebenza kwemishini nokusebenza okuchotshozwayo, indlela yokuthuthukisa imi kanje:

Sebenzisa induku engu-6063B enokwakheka kwe-alloy eyinhloko ye-Si 0.38-0.41% kanye ne-Mg 0.53-0.60%.

Yenza ukucisha komoya nokuguga okwenziwayo ukuze ufinyelele isimo se-T6.

Sebenzisa inkungu + ukucisha umoya futhi uphathe ukwelashwa kokuguga ngokweqile ukuze ufinyelele isimo se-T7.

3 Ukukhiqizwa Komshayeli

3.1 Izimo Zokukhipha

Ukukhiqizwa kwenziwa kumshini wokunyathelisa we-2000T we-extrusion one-extrusion ratio ye-36. Izinto ezisetshenziswayo yi-homogenized aluminium rod 6063B. Amazinga okushisa okushisa enduku ye-aluminium ami kanje: IV zone 450-III zone 470-II zone 490-1 zone 500. Ingcindezi yokuphumelela yesilinda eyinhloko izungeze ibha engu-210, nesigaba esizinzile se-extrusion esinengcindezi ye-extrusion eduze nebha engu-180. Isivinini se-extrusion shaft singu-2.5 mm/s, kanti isivinini se-profile extrusion ngu-5.3 m/min. Izinga lokushisa endaweni ye-extrusion ngu-500-540°C. Ukucisha kwenziwa kusetshenziswa ukupholisa komoya ngamandla efeni angakwesokunxele angu-100%, amandla efeni amaphakathi abe ngu-100%, kanye namandla efeni angakwesokudla angu-50%. Izinga lokupholisa elimaphakathi phakathi kwendawo yokucisha lifinyelela ku-300-350°C/min, futhi izinga lokushisa ngemva kokuphuma endaweni yokucisha lingu-60-180°C. Ukuze kucishwe inkungu + komoya, izinga lokupholisa elimaphakathi phakathi kwendawo yokushisisa lifinyelela ku-430-480°C/min, futhi izinga lokushisa ngemva kokuphuma endaweni yokucisha lingu-50-70°C. Iphrofayela ayibonisi ukugoba okubalulekile.

3.2 Ukuguga

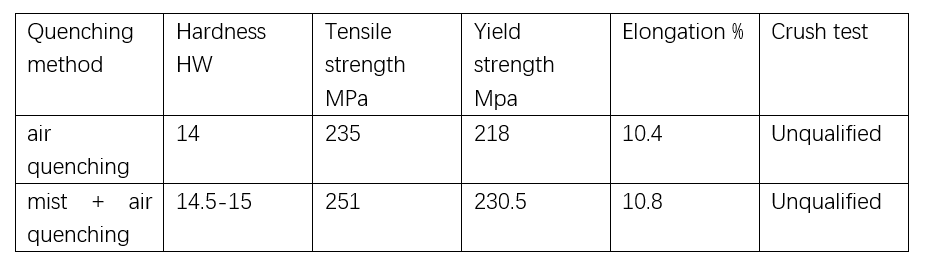

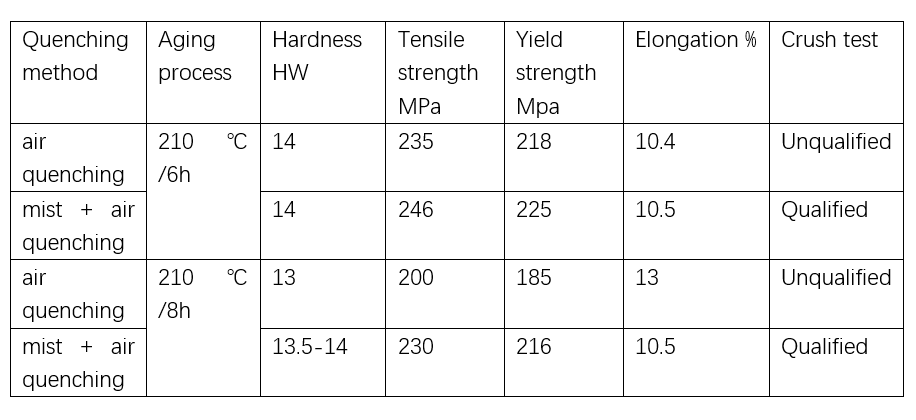

Ukulandela inqubo yokuguga ye-T6 ku-185 ° C amahora angu-6, ubulukhuni bempahla kanye nezakhiwo zemishini zimi kanje:

Ngokwenqubo yokuguga ye-T7 ku-210 ° C amahora angu-6 namahora angu-8, ukuqina kwempahla kanye nezakhiwo zemishini zimi kanje:

Ngokusekelwe kudatha yokuhlola, indlela yokucima inkungu + komoya, ehlanganiswe nenqubo yokuguga engu-210°C/6h, ihlangabezana nezimfuneko zakho kokubili ukusebenza komshini nokuhlola okuchotshozayo. Uma kucatshangelwa ukusebenza kahle kwezindleko, indlela yenkungu + yokucisha umoya kanye nenqubo yokuguga engu-210°C/6h yakhethelwa ukukhiqizwa ukuze kuhlangatshezwane nezidingo zomkhiqizo.

3.3 Isivivinyo Sokuchoboza

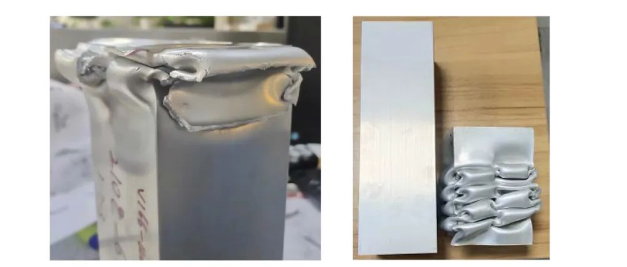

Ngenduku yesibili neyesithathu, isiphetho sekhanda sinqunywa ngo-1.5m, kanti umsila unqunywe ngo-1.2m. Amasampula amabili lilinye lithathwa engxenyeni yekhanda, ephakathi, neyomsila, enobude obungama-300mm. Ukuhlolwa kokuchotshozwa kwenziwa ngemva kokuguga ku-185°C/6h naku-210°C/6h kanye no-8h (idatha yokusebenza komshini njengoba kushiwo ngenhla) emshinini wokuhlola impahla yendawo yonke. Ukuhlolwa kwenziwa ngesivinini sokulayisha esingu-100 mm/min ngenani lokucindezelwa elingu-70%. Imiphumela imi kanje: ngenkungu + yokucisha umoya ngezinqubo zokuguga ze-210 ° C / 6h kanye ne-8h, ukuhlolwa okuchotshozwayo kuhlangabezana nezidingo, njengoba kuboniswe kuMfanekiso 3-2, kuyilapho amasampula acinywa emoyeni abonisa ukuqhekeka kuzo zonke izinqubo zokuguga.

Ngokusekelwe emiphumeleni yokuhlola echotshozayo, inkungu + ukucisha umoya ngezinqubo zokuguga ezingu-210°C/6h no-8h kuhlangabezana nezimfuneko zekhasimende.

4 Isiphetho

Ukwenziwa kahle kwezinqubo zokucisha nokuguga kubalulekile ekuthuthukisweni ngempumelelo komkhiqizo futhi kunikeza isixazululo esifanelekile somkhiqizo webhokisi lokuphahlazeka.

Ngokuhlolwa okubanzi, kunqunywe ukuthi isimo sempahla yomkhiqizo webhokisi lokuphahlazeka kufanele sibe ngu-6063-T7, indlela yokucisha inkungu + ukupholisa umoya, futhi inqubo yokuguga engu-210 ° C/6h iyisinqumo esingcono kakhulu sokukhipha izinduku ze-aluminium ezinamazinga okushisa asukela ku-480-500 ° C, isivinini se-extrusion extrusion engu-2.500 ° C, i-extrusion shaft engu-2.500 ° C, isivinini esingu-2.5 mm kanye nezinga lokushisa le-extrusion elingu-500-540°C.

Ihlelwe nguMay Jiang evela kwaMAT Aluminium

Isikhathi sokuthumela: May-07-2024