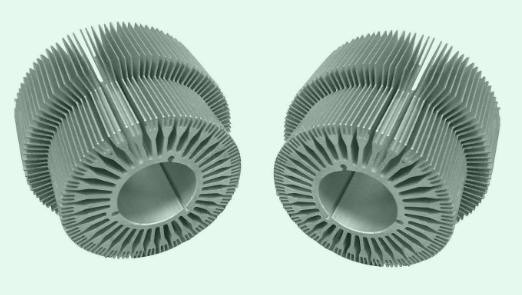

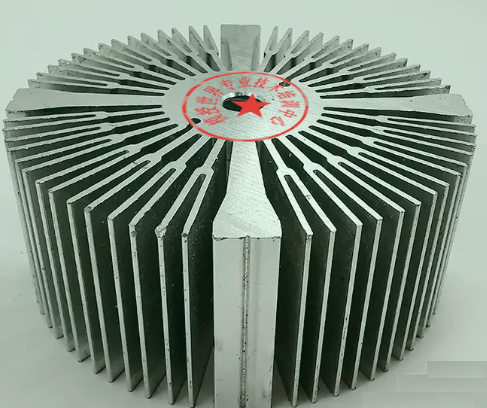

Ngenxa yokuthi ama-alloys e-aluminium angasindi, amahle, anokumelana nokugqwala okuhle, futhi ane-conductivity eshisayo ehle kakhulu kanye nokusebenza kokucubungula, asetshenziswa kabanzi njengezingxenye zokukhipha ukushisa embonini ye-IT, izimboni ze-electronics kanye nezimoto, ikakhulukazi embonini ye-LED ekhulayo okwamanje. Lezi zingxenye zokukhipha ukushisa kwe-aluminium ingxubevange zinemisebenzi emihle yokukhipha ukushisa. Ekukhiqizeni, isihluthulelo sokukhiqizwa okuphumelelayo kwe-extrusion yalawa maphrofayili we-radiator yisikhunta. Ngenxa yokuthi lawa maphrofayili ngokuvamile anezici zamazinyo amakhulu naminyene okukhipha ukushisa kanye namashubhu amade amisiwe, isakhiwo sendabuko esiyisicaba, isakhiwo sokufa esihlukanisiwe kanye nesakhiwo sokufa sephrofayili esingenalutho asikwazi ukuhlangabezana kahle nezidingo zamandla esikhunta nokubunjwa kwe-extrusion.

Njengamanje, amabhizinisi athembele kakhulu kwikhwalithi yensimbi yokubumba. Ukuze kuthuthukiswe amandla esikhunta, abanqikazi ukusebenzisa insimbi ebizayo evela kwamanye amazwe. Izindleko zesikhunta ziphezulu kakhulu, futhi isilinganiso sangempela sempilo yesikhunta singaphansi kwe-3t, okuholela ekutheni intengo yemakethe ye-radiator ibe phezulu ngokuqhathaniswa, ikhawulela ngokungathi sína ukukhushulwa nokwandiswa kwezibani ze-LED. Ngakho-ke, i-extrusion iyafa ngenxa yamaphrofayili erediyetha amise okwe-sunflower adonse ukunaka okukhulu konjiniyela kanye nabasebenzi bezobuchwepheshe embonini.

Lesi sihloko sethula ubuchwepheshe obuhlukahlukene bephrofayili ye-radiator ye-sunflower extrusion etholwe eminyakeni yocwaningo olunzima nokukhiqizwa kwesilingo esiphindaphindiwe ngezibonelo ekukhiqizeni kwangempela, ukuze kubhekiswe kontanga.

1. Ukuhlaziywa kwezici zesakhiwo sezigaba zephrofayela ye-aluminium

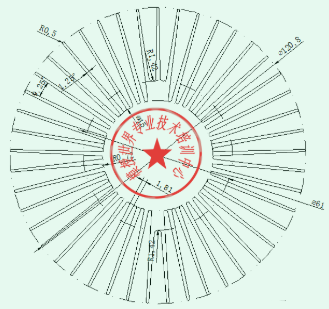

Umfanekiso 1 ubonisa ingxenye ephambanayo yephrofayili ye-aluminium yeradiyetha yelanga yelanga. Indawo ephambanayo yephrofayili ingu-7773.5mm², enamazinyo angama-40 aqeda ukushisa. Ubukhulu bosayizi wokuvula wokulenga owenziwe phakathi kwamazinyo ngu-4.46 mm. Ngemva kokubala, isilinganiso solimi phakathi kwamazinyo singu-15.7. Ngesikhathi esifanayo, kukhona indawo enkulu eqinile phakathi nendawo yephrofayili, enendawo engu-3846.5mm².

Uma sibheka izici zomumo wephrofayili, isikhala phakathi kwamazinyo singathathwa njengamaphrofayili angenalutho, futhi iphrofayili yerediyetha yakhiwe ngamaphrofayili amaningi angenalutho. Ngakho-ke, lapho uklama isakhiwo sesikhunta, isihluthulelo siwukucabangela indlela yokuqinisekisa amandla esikhunta. Nakuba kumaphrofayili angama-semi-hollow, imboni iye yasungula izinhlobonhlobo zezakhiwo zokubunjwa ezivuthiwe, njengokuthi "isikhunta se-splitter esimboziwe", "isikhunta esihlukanisayo esinqunyiwe", "isikhunta sokuhlukanisa ibhuloho lokumiswa", njll. Kodwa-ke, lezi zakhiwo azisebenzi emikhiqizweni eyakhiwe amaphrofayili amaningi angenalutho. Idizayini yendabuko ibheka izinto zokwakha kuphela, kepha ekubumbeni kwe-extrusion, umthelela omkhulu emandleni amandla okukhipha ngesikhathi senqubo ye-extrusion, futhi inqubo yokwenza insimbi iyisici esiyinhloko esidala amandla e-extrusion.

Ngenxa yendawo enkulu eqinile emaphakathi yephrofayili ye-radiator yelanga, kulula kakhulu ukubangela ukuthi izinga lokugeleza lilonke kule ndawo lisheshe kakhulu ngesikhathi senqubo ye-extrusion, futhi ukucindezeleka okuqinile okungeziwe kuzokwenziwa ekhanda leshubhu yokumisa i-intertooth, okuholela ekuqhekekeni kweshubhu yokumiswa kwe-intertooth. Ngakho-ke, ekwakhiweni kwesakhiwo sesikhunta, kufanele sigxile ekulungiseni izinga lokugeleza kwensimbi kanye nezinga lokugeleza ukuze kuzuzwe inhloso yokunciphisa ukucindezela kwe-extrusion nokuthuthukisa isimo sokucindezeleka kwepayipi elimisiwe phakathi kwamazinyo, ukuze kuthuthukiswe amandla esikhunta.

2. Ukukhethwa kwesakhiwo sesikhunta kanye nomthamo wokucindezela we-extrusion

2.1 Ifomu lesakhiwo sesikhunta

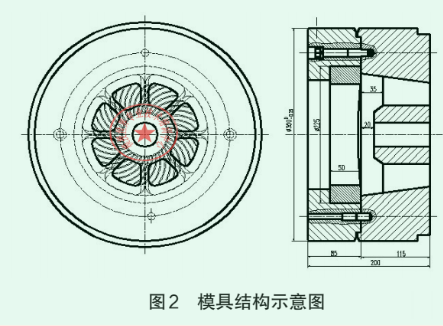

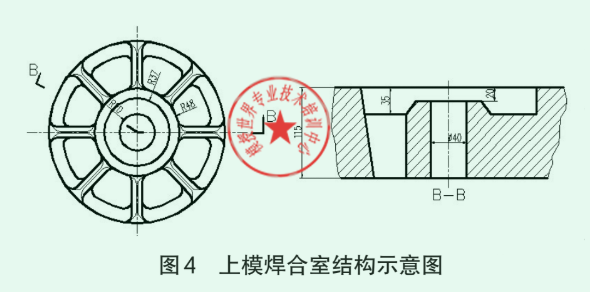

Ukuze uthole iphrofayili ye-radiator ye-sunflower eboniswe ku-Figure 1, nakuba ingenayo ingxenye engenalutho, kufanele ithathe isakhiwo sesikhunta esihlukanisiwe njengoba kuboniswe kuMfanekiso 2. Ngokungafani nesakhiwo sesikhunta se-shunt esivamile, ikamelo lesiteshi se-soldering sensimbi lifakwe esikhunjini esiphezulu, futhi isakhiwo sokufaka sisetshenziswa esikhunjini esingaphansi. Inhloso ukunciphisa izindleko zesikhunta futhi unciphise umjikelezo wokukhiqiza isikhunta. Kokubili amasethi esikhunta angaphezulu naphansi akhona yonke indawo futhi angasetshenziswa kabusha. Okubaluleke nakakhulu, amabhulokhi we-die hole angacutshungulwa ngokuzimela, angaqinisekisa kangcono ukunemba kwebhande lomsebenzi we-die hole. Umgodi ongaphakathi wesikhunta esiphansi uklanywe njengesinyathelo. Ingxenye engenhla kanye nebhulokhi yembobo yokubunjwa kusebenzisa indawo yokuvula, futhi inani legebe nhlangothi zombili lingu-0.06~0.1m; ingxenye engezansi ithatha ukulingana kokuphazanyiswa, futhi inani lokuphazanyiswa ezinhlangothini zombili liyi-0.02 ~ 0.04m, okusiza ukuqinisekisa ukuthi i-coaxiality futhi kusiza ukuhlangana, okwenza ukulingana kwe-inlay kuhlangene kakhulu, futhi ngesikhathi esifanayo, kungagwema ukuguqulwa kwesikhunta okubangelwa ukufakwa kokuphazanyiswa kokufakwa kokushisa.

2.2 Ukukhethwa komthamo we-extruder

Ukukhethwa komthamo we-extruder, ngakolunye uhlangothi, ukucacisa ububanzi obufanele bangaphakathi bomgqomo we-extrusion kanye nokucindezela okukhulu okuqondile kwe-extruder engxenyeni yombhobho we-extrusion ukuhlangabezana nengcindezi ngesikhathi sokwakhiwa kwensimbi. Ngakolunye uhlangothi, kuwukunquma isilinganiso esifanele se-extrusion bese ukhetha ukucaciswa kosayizi wesikhunta esifanele ngokusekelwe ezindlekweni. Ngephrofayili ye-aluminium yeradiyetha kabhekilanga, isilinganiso se-extrusion asikwazi ukuba sikhulu kakhulu. Isizathu esiyinhloko ukuthi amandla e-extrusion alingana ne-extrusion ratio. Uma sikhulu isilinganiso se-extrusion, amandla amakhulu e-extrusion. Lokhu kulimaza kakhulu isikhunta sephrofayili ye-sunflower radiator radiator.

Okuhlangenwe nakho kubonisa ukuthi isilinganiso se-extrusion samaphrofayili e-aluminium yama-radiator ka-sunflower angaphansi kwama-25. Kuphrofayili eboniswe kuMfanekiso 1, i-extruder engu-20.0 MN ene-extrusion barrel ububanzi obuyi-208 mm ikhethiwe. Ngemva kokubala, ukucindezela okukhulu okukhethekile kwe-extruder ngu-589MPa, okuyinani elifaneleke kakhulu. Uma ukucindezela okuqondile kuphezulu kakhulu, ukucindezela kwesikhunta kuzoba kukhulu, okulimaza impilo yesikhunta; uma ingcindezi ethile iphansi kakhulu, ayikwazi ukuhlangabezana nezidingo ze-extrusion forming. Okuhlangenwe nakho kubonisa ukuthi ingcindezi ethile ebangeni elingu-550~750 MPa ingahlangabezana kangcono nezidingo zenqubo ehlukahlukene. Ngemva kokubala, i-extrusion coefficient ingu-4.37. Ukucaciswa kosayizi wesikhunta kukhethwa njengo-350 mmx200 mm (ububanzi bangaphandle x degrees).

3. Ukunqunywa kwemingcele yesakhiwo sesikhunta

3.1 Imingcele yesakhiwo sesikhunta esiphezulu

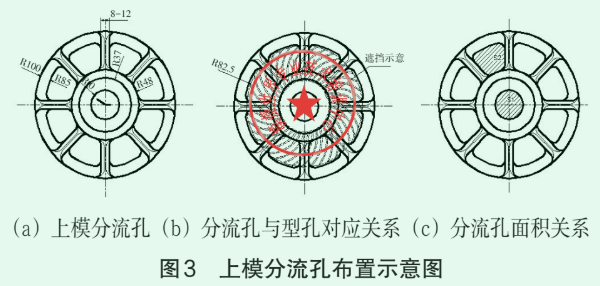

(1) Inombolo nokuhlelwa kwezimbobo zokuphambukisa. Ukuze iphrofayili ye-radiator ye-sunflower shunt isikhunta, inani lemigodi ye-shunt liyanda, lingcono. Kumaphrofayili anomumo oyisiyingi ofanayo, izimbobo ze-shunt ezijwayelekile ezi-3 ukuya kwezi-4 zivame ukukhethwa. Umphumela uba ukuthi ububanzi bebhuloho le-shunt bukhulu. Ngokuvamile, uma likhulu kuno-20mm, inani lama-welds lincane. Kodwa-ke, lapho ukhetha ibhande lokusebenza lembobo yokufa, ibhande lokusebenza lembobo yokufa ngaphansi kwebhuloho le-shunt kumele libe lifushane. Ngaphansi kwesimo sokuthi ayikho indlela yokubala eqondile yokukhethwa kwebhande elisebenzayo, kuzokwenza ngokwemvelo ukuthi imbobo yokufa ngaphansi kwebhuloho nezinye izingxenye zingafinyeleli izinga lokugeleza elifanayo ngesikhathi sokukhipha ngenxa yomehluko webhande elisebenzayo, Lo mehluko wezinga lokugeleza uzoveza ukucindezeleka okwengeziwe okuqinile ku-cantilever futhi kubangele ukuphambuka kwamazinyo okukhipha ukushisa. Ngakho-ke, i-radiator sunflower extrusion ifa ngenani eliminyene lamazinyo, kubaluleke kakhulu ukuqinisekisa ukuthi izinga lokugeleza kwezinyo ngalinye lihambisana. Njengoba inani lezimbobo ze-shunt likhula, inani lamabhuloho e-shunt lizokhula ngokufanele, futhi izinga lokugeleza nokusabalalisa kokugeleza kwensimbi kuzoba ngaphezulu. Lokhu kungenxa yokuthi njengoba inani lamabhuloho e-shunt likhula, ububanzi bamabhuloho e-shunt bungancishiswa ngokufanele.

Idatha esebenzayo ikhombisa ukuthi isibalo sezimbobo ze-shunt ngokuvamile si-6 noma 8, noma ngaphezulu. Yiqiniso, kwamanye amaphrofayli amakhulu okuchithwa kokushisa kukabhekilanga, isikhunta esiphezulu singaphinde sihlele izimbobo ze-shunt ngokuvumelana nesimiso sobubanzi bebhuloho le-shunt ≤ 14mm. Umehluko wukuthi ipuleti elihlukanisayo langaphambili kufanele lengezwe ukuze kusatshalaliswe kusengaphambili futhi kulungiswe ukugeleza kwensimbi. Inombolo kanye nokuhlelwa kwezimbobo ze-diverter epuleti le-diverter yangaphambili kungenziwa ngendlela yendabuko.

Ngaphezu kwalokho, lapho uhlela izimbobo ze-shunt, kufanele kucatshangelwe ukusebenzisa isikhunta esiphezulu ukuze kuvikelwe ngokufanelekile ikhanda le-cantilever yezinyo lokushisa ukushisa ukuze kuvinjelwe insimbi ekushayeni ngokuqondile ikhanda le-cantilever tube futhi ngaleyo ndlela ithuthukise isimo sokucindezeleka se-cantilever tube. Ingxenye evinjiwe yekhanda le-cantilever phakathi kwamazinyo ingaba ngu-1/5~1/4 wobude beshubhu le-cantilever. Ukuhlelwa kwezimbobo ze-shunt kuboniswe kuMfanekiso 3

(2) Ubudlelwano bendawo yembobo ye-shunt. Ngenxa yokuthi ubukhulu bodonga lwempande yezinyo elishisayo buncane futhi ukuphakama kukude nendawo, futhi indawo ebonakalayo ihluke kakhulu phakathi nendawo, yingxenye enzima kakhulu yokwenza insimbi. Ngakho-ke, iphuzu elibalulekile ekwakhiweni kwesikhunta sephrofayili yeradiyetha kabhekilanga ukwenza izinga lokugeleza lengxenye eqinile emaphakathi lihambe kancane ngangokunokwenzeka ukuze kuqinisekiswe ukuthi insimbi kuqala igcwalisa impande yezinyo. Ukuze kuzuzwe umphumela onjalo, ngakolunye uhlangothi, ukukhethwa kwebhande lokusebenza, futhi okubaluleke nakakhulu, ukuzimisela kwendawo ye-diverter hole, ikakhulukazi indawo yengxenye ephakathi ehambisana nembobo ye-diverter. Ukuhlola kanye namagugu abonisa ukuthi umphumela omuhle ufinyelelwa lapho indawo yembobo emaphakathi ye-diverter S1 kanye nendawo yembobo ye-diverter eyodwa yangaphandle S2 yanelisa ubudlelwano obulandelayo: S1= (0.52 ~0.72) S2

Ukwengeza, umzila osebenzayo wokugeleza kwensimbi wembobo ehlukanisayo emaphakathi kufanele ube ngu-20 ~ 25mm ubude kunomzila osebenzayo wokugeleza kwensimbi wembobo ehlukanisayo yangaphandle. Lobu bude bubuye bucabangele umkhawulo kanye nokwenzeka kokulungisa isikhunta.

(3) Ukujula kwegumbi lokushisela. I-sunflower profile ye-radiator extrusion die yehlukile kune-shunt die yendabuko. Igumbi layo lonke lokushisela kufanele libe endaweni engaphezulu. Lokhu kuqinisekisa ukunemba kokucubungula i-hole block ye-die ephansi, ikakhulukazi ukunemba kwebhande lokusebenza. Uma kuqhathaniswa nesikhunta se-shunt esivamile, ukujula kwegumbi lokushisela le-sunflower radiator profile shunt mold kudinga ukwanda. Umthamo omkhulu womshini we-extrusion, ukwanda okukhulu kokujula kwegumbi lokushisela, okuyi-15 ~ 25mm. Isibonelo, uma kusetshenziswa umshini we-20 MN extrusion, ukujula kwegumbi lokushisela le-shunt die yendabuko kungu-20 ~ 22mm, kanti ukujula kwegumbi lokushisela le-shunt die yephrofayili ye-radiator kabhekilanga kufanele kube ngu-35 ~ 40 mm. Inzuzo yalokhu ukuthi insimbi ihlanganiswe ngokugcwele futhi ukucindezeleka kwepayipi elimisiwe kuyancipha kakhulu. Isakhiwo segumbi lokushisela isikhunta esiphezulu siboniswe kuMfanekiso 4.

3.2 Idizayini yokufaka imbobo yokufa

Idizayini ye-block hole block ikakhulukazi ihlanganisa usayizi wembobo yokufa, ibhande lokusebenza, ububanzi bangaphandle kanye nobukhulu bebhulokhi yesibuko, njll.

(1) Ukunqunywa kosayizi wembobo yokufa. Usayizi wembobo yokufa unganqunywa ngendlela yendabuko, ikakhulukazi kucatshangelwa ukukalwa kokucubungula okushisayo kwe-alloy.

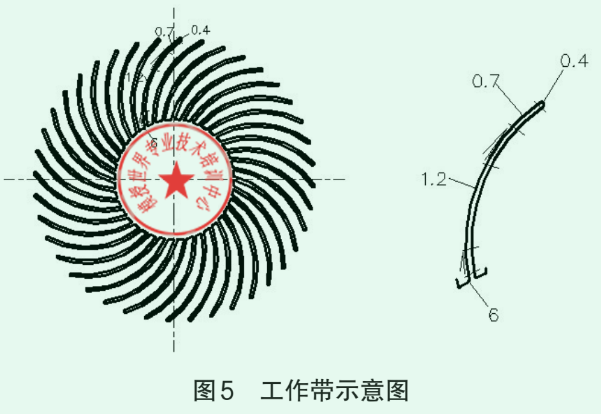

(2) Ukukhethwa kwebhande lomsebenzi. Umgomo wokukhethwa kwebhande lokusebenza kuqala ukuqinisekisa ukuthi ukunikezwa kwayo yonke insimbi phansi kwempande yezinyo kwanele, ukuze izinga lokugeleza phansi kwempande yezinyo lisheshe kunezinye izingxenye. Ngakho-ke, ibhande elisebenzayo elingaphansi kwempande yezinyo kufanele libe mfushane kakhulu, ngenani lika-0.3 ~ 0.6mm, futhi ibhande elisebenzayo ezingxenyeni eziseduze kufanele lenyuke ngo-0.3mm. Umgomo ukwandisa ngo-0.4~0.5 njalo ngo-10~15mm ukuya enkabeni; okwesibili, ibhande elisebenzayo engxenyeni enkulu eqinile yesikhungo akufanele lidlule u-7mm. Uma kungenjalo, uma umehluko wobude bebhande lokusebenza mkhulu kakhulu, amaphutha amakhulu azokwenzeka ekucubunguleni ama-electrode ethusi kanye nokucubungula kwe-EDM kwebhande elisebenzayo. Leli phutha lingabangela kalula ukuphambuka kwamazinyo ngesikhathi senqubo ye-extrusion. Ibhande lomsebenzi liboniswe kuMfanekiso 5.

(3) Ububanzi obungaphandle kanye nokujiya kokufakwayo. Ezibunjeni zendabuko ze-shunt, ubukhulu bokufakwa kwe-die hole ubukhulu besikhunta esiphansi. Kodwa-ke, ngesikhunta serediyetha yelanga, uma ubukhulu obusebenzayo bembobo yokufa bukhulu kakhulu, iphrofayili izongqubuzana kalula nesikhunta ngesikhathi sokukhipha nokukhipha, okuholela emazinyweni angalingani, imihuzuko noma ngisho nokugedla kwamazinyo. Lokhu kuzokwenza amazinyo aphuke.

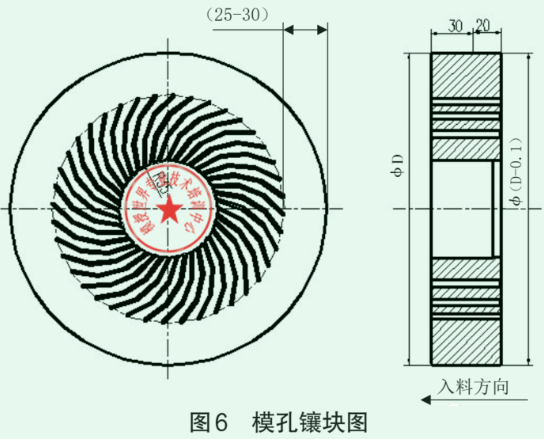

Ngaphezu kwalokho, uma ubukhulu bomgodi wokufa bude kakhulu, ngakolunye uhlangothi, isikhathi sokucubungula side ngesikhathi senqubo ye-EDM, futhi ngakolunye uhlangothi, kulula ukubangela ukuphambuka kokugqwala kagesi, futhi kulula futhi ukubangela ukuphambuka kwamazinyo ngesikhathi sokukhipha. Yiqiniso, uma ubukhulu bembobo yokufa buncane kakhulu, amandla amazinyo awanakuqinisekiswa. Ngakho-ke, kucatshangelwa lezi zici ezimbili, isipiliyoni sibonisa ukuthi idigri yokufaka imbobo yokufa yesikhunta esiphansi ngokuvamile i-40 kuya ku-50; futhi ububanzi obungaphandle bembobo yokufa kufanele bube ngu-25 kuya ku-30 mm ukusuka onqenqemeni olukhulu lwembobo yokufa kuya kuyindilinga yangaphandle yokufaka.

Kuphrofayili ekhonjiswe kuMfanekiso 1, ububanzi bangaphandle nogqinsi lwebhulokhi ye-die hole ngu-225mm no-50mm ngokulandelana. Ukufakwa kwembobo yokufa kuboniswe kuMfanekiso 6. D emfanekisweni uwusayizi wangempela futhi usayizi wegama ungu-225mm. Ukuchezuka okulinganiselwe kobukhulu bawo bangaphandle kufaniswe ngokuvumelana nembobo engaphakathi yesikhunta esingaphansi ukuze kuqinisekiswe ukuthi igebe elihlangothini olulodwa lingaphakathi kobubanzi obungu-0.01~0.02mm. Ibhulokhi yembobo yokufa ibonisiwe kuMfanekiso 6. Usayizi wembobo ongaphakathi wembobo yokufa obekwe esikhunjeni esingezansi ungama-225mm. Ngokusekelwe kusayizi wangempela okaliwe, ibhulokhi yembobo yokufa ifaniswe ngokomgomo ongu-0.01~0.02mm ohlangothini ngalunye. Ububanzi obungaphandle bebhulokhi ye-die hole ingatholakala njengo-D, kodwa ukuze kube lula ukufakwa, ububanzi bangaphandle bebhokisi lesibuko se-die hole bungancishiswa ngokufanelekile phakathi kwebanga elingu-0.1m ekugcineni kokuphakelayo, njengoba kuboniswe esithombeni.

4. Ubuchwepheshe obubalulekile bokukhiqiza isikhunta

Ukucutshungulwa kwesikhunta sephrofayili yeradiyetha kabhekilanga akufani kakhulu naleyo yezibunji ezijwayelekile zephrofayili ye-aluminium. Umehluko osobala ubonakala ngokuyinhloko ekucutshungulweni kukagesi.

(1) Ngokuphathelene nokusika ucingo, kuyadingeka ukuvimbela ukuguqulwa kwe-electrode yethusi. Ngenxa yokuthi i-electrode yethusi esetshenziselwa i-EDM inzima, amazinyo mancane kakhulu, i-electrode ngokwayo ithambile, inokuqina okubuthakathaka, futhi izinga lokushisa eliphezulu lendawo elikhiqizwa ukusika ucingo kubangela ukuba i-electrode ikhubazeke kalula phakathi nenqubo yokusika ucingo. Uma usebenzisa ama-electrode ethusi akhubazekile ukucubungula amabhande okusebenza nemibese engenalutho, amazinyo asontekile azokwenzeka, angabangela kalula ukuthi isikhunta sikhishwe ngesikhathi sokucubungula. Ngakho-ke, kuyadingeka ukuvimbela ukuguqulwa kwama-electrode ethusi ngesikhathi senqubo yokukhiqiza ku-inthanethi. Izinyathelo eziyinhloko zokuvimbela yilezi: ngaphambi kokusika ucingo, linganisa ibhulokhi yethusi ngombhede; sebenzisa inkomba yokudayela ukulungisa ukuma ekuqaleni; lapho usika ucingo, qala engxenyeni yezinyo kuqala, futhi ekugcineni usike ingxenye ngodonga oluwugqinsi; Ngaso sonke isikhathi, sebenzisa izintambo zesiliva ezilahliwe ukuze ugcwalise izingxenye ezisikiwe; ngemva kokwenziwa kocingo, sebenzisa umshini wocingo ukuze unqamule ingxenye emfushane engaba ngu-4 mm ngobude be-electrode yethusi esikiwe.

(2) Umshini wokukhipha ugesi ngokusobala uhlukile esikhunjeni esivamile. I-EDM ibaluleke kakhulu ekucubunguleni isikhunta sephrofayili ye-radiator sunflower. Ngisho noma umklamo uphelele, iphutha elincane ku-EDM lizokwenza ukuthi isikhunta sonke sicishwe. Umshini wokukhipha ugesi awuncikile kumishini njengokusika kwezintambo. Kuncike kakhulu emakhonweni okusebenza kanye nobuchule bomsebenzisi. Umshini wokukhipha ugesi ikakhulukazi unaka amaphuzu amahlanu alandelayo:

①Umshini womshini wokukhipha ugesi. I-7~10 I-current ingasetshenziselwa umshini wokuqala we-EDM ukuze unciphise isikhathi sokucubungula; I-5 ~ 7 I-current ingasetshenziselwa ukuqedela imishini. Inhloso yokusebenzisa umsinga omncane ukuthola indawo enhle;

② Qinisekisa ukucaba kobuso bokuphela kwesikhunta kanye nokuma kwe-electrode yethusi. Ukungafinyeleli kahle kobuso bokuphela kwesikhunta noma ukuphakama okunganele kwe-electrode yethusi kwenza kube nzima ukuqinisekisa ukuthi ubude bebhande lomsebenzi ngemva kokucubungula kwe-EDM buhambisana nobude bebhande lomsebenzi oklanyelwe. Kulula ukuthi inqubo ye-EDM yehluleke noma ingene ngisho nebhande lomsebenzi elinamazinyo. Ngakho-ke, ngaphambi kokucubungula, umshini wokugaya kufanele usetshenziselwe ukuthambisa iziphetho zombili zesikhunta ukuze uhlangabezane nezidingo zokunemba, futhi inkomba yokudayela kufanele isetshenziselwe ukulungisa ukuma kwe-electrode yethusi;

③ Qinisekisa ukuthi igebe phakathi kwemibese engenalutho lilingana. Ngesikhathi somshini wokuqala, hlola ukuthi ithuluzi elingenalutho liyasuswa yini njalo ngo-0.2 mm njalo ngo-3 kuya ku-4 mm wokucubungula. Uma i-offset inkulu, kuyoba nzima ukuyilungisa ngokulungiswa okulandelayo;

④Susa okusele okukhiqizwe ngesikhathi senqubo ye-EDM ngesikhathi. I-spark discharge corrosion izokhiqiza inani elikhulu lezinsalela, okumele zihlanzwe ngesikhathi, ngaphandle kwalokho ubude bebhande lokusebenza buzohluka ngenxa yokuphakama okuhlukene kwezinsalela;

⑤Isikhunta kufanele sisuswe uzibuthe ngaphambi kwe-EDM.

5. Ukuqhathaniswa kwemiphumela ye-extrusion

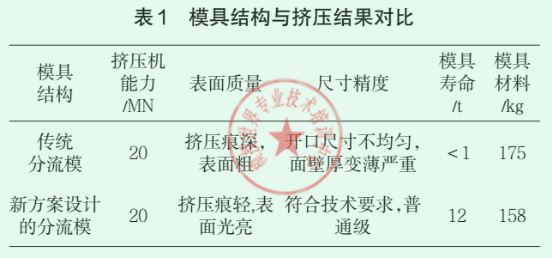

Iphrofayela eboniswe kuMfanekiso 1 ihlolwe kusetshenziswa isikhunta sokuhlukanisa esivamile kanye nohlelo olusha lomklamo oluhlongozwayo kulesi sihloko. Ukuqhathaniswa kwemiphumela kukhonjisiwe kuThebula 1.

Kungabonakala emiphumeleni yokuqhathanisa ukuthi isakhiwo sesikhunta sinethonya elikhulu empilweni yesikhunta. Isikhunta esiklanywe kusetshenziswa uhlelo olusha sinezinzuzo ezisobala futhi sithuthukisa kakhulu impilo yesikhunta.

6. Isiphetho

Isikhunta se-extrusion sephrofayili yeradiyetha kabhekilanga siwuhlobo lwesikhunta okunzima kakhulu ukuklama nokwenza, futhi ukwakheka nokukhiqizwa kwaso kuyinkimbinkimbi. Ngakho-ke, ukuqinisekisa izinga lempumelelo ye-extrusion kanye nempilo yesevisi yesikhunta, amaphuzu alandelayo kufanele azuzwe:

(1) Ifomu lesakhiwo sesikhunta kufanele likhethwe ngokufanele. Ukwakheka kwesikhunta kumele kube kuhle ekunciphiseni amandla e-extrusion ukunciphisa ukucindezeleka ku-cantilever yesikhunta esakhiwe ngamazinyo okushisa ukushisa, ngaleyo ndlela kuthuthukise amandla esikhunta. Isihluthulelo ukucacisa ngokunengqondo inombolo nokuhlelwa kwezimbobo ze-shunt kanye nendawo yezimbobo ze-shunt neminye imingcele: okokuqala, ububanzi bebhuloho le-shunt elakhiwe phakathi kwezimbobo ze-shunt akufanele lidlule i-16mm; Okwesibili, indawo yokuhlukanisa imbobo kufanele inqunywe ukuze isilinganiso sokuhlukaniswa sifinyelele ngaphezu kwe-30% ye-extrusion ratio ngangokunokwenzeka ngenkathi kuqinisekiswa amandla esikhunta.

(2) Khetha ngokunengqondo ibhande lomsebenzi futhi uthathe izinyathelo ezifanele ngesikhathi somshini kagesi, okuhlanganisa ubuchwepheshe bokucubungula ama-electrode ethusi namapharamitha ajwayelekile kagesi womshini kagesi. Iphuzu lokuqala eliyisihluthulelo liwukuthi i-electrode yethusi kufanele ibe phezulu ngaphambi kokusika ucingo, futhi indlela yokufaka kufanele isetshenziswe ngesikhathi sokusika ucingo ukuze kuqinisekiswe. Ama-electrode awakhululekile noma akhubazekile.

(3) Phakathi nenqubo yomshini kagesi, i-electrode kufanele ihambisane ngokunembile ukuze kugwenywe ukuchezuka kwamazinyo. Yiqiniso, ngesisekelo sokuklama nokukhiqiza okunengqondo, ukusetshenziswa kwensimbi yesikhunta esishisayo esisezingeni eliphezulu kanye nenqubo yokwelapha ukushisa kwe-vacuum yentukuthelo emithathu noma ngaphezulu kungakhulisa amandla esikhunta futhi kuzuze imiphumela engcono. Kusukela ekwakhiweni, ukukhiqiza kuya ekukhiqizeni kwe-extrusion, kuphela uma isixhumanisi ngasinye sinembile lapho singaqinisekisa ukuthi isikhunta sephrofayili yerediyetha kabhekilanga siyakhishwa.

Isikhathi sokuthumela: Aug-01-2024