1 Isingeniso

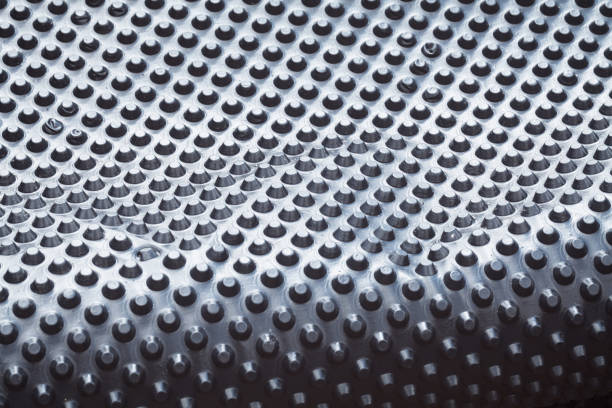

Ngokuthuthuka okusheshayo kwemboni ye-aluminium kanye nokwanda okuqhubekayo kwamathani emishini ye-aluminium extrusion, ubuchwepheshe be-porous mold aluminium extrusion buye bavela. I-aluminium extrusion ye-porous mold ithuthukisa kakhulu ukusebenza kahle kokukhiqizwa kwe-extrusion futhi ibeka nezidingo eziphezulu zobuchwepheshe ekwakhiweni kwesikhunta kanye nezinqubo zokukhipha.

2 Inqubo yokukhipha

Umthelela wenqubo ye-extrusion ekusebenzeni kahle kokukhiqizwa kwe-porous mold aluminium extrusion ubonakala ikakhulukazi ekulawuleni izici ezintathu: izinga lokushisa elingenalutho, izinga lokushisa lesikhunta, nezinga lokushisa lokuphuma.

2.1 Izinga lokushisa elingenalutho

Izinga lokushisa elilinganayo elingenalutho linomthelela omkhulu ekukhishweni kwe-extrusion. Emkhiqizweni wangempela, imishini yokukhipha i-extrusion ethambekele ekuguquguqukeni kwendawo ngokuvamile ifudunyezwa kusetshenziswa iziko elingenalutho. Izithando zomlilo eziningi ezingenalutho zihlinzeka ngokufudumeza okufanayo okufana nokungenasici okunezici ezinhle zokuvikela. Ukwengeza, ukuze kuqinisekiswe ukusebenza kahle okuphezulu, indlela "yokushisa ephansi nesivinini esikhulu" ivame ukusetshenziswa. Kulesi simo, izinga lokushisa elingenalutho kanye nezinga lokushisa lokuphuma kufanele lihambisane eduze nesivinini sokukhipha, ngezilungiselelo ezicabangela izinguquko ekucindezelweni kwe-extrusion kanye nesimo sendawo engenalutho. Izilungiselelo zokushisa ezingenalutho zincike ezimweni zangempela zokukhiqiza, kodwa njengesiqondiso esijwayelekile, ngokukhipha isikhunta esinezimbotshana, amazinga okushisa angenalutho ngokuvamile agcinwa phakathi kuka-420-450°C, nama-flat dies abekwe phezulu kancane ngo-10-20°C uma kuqhathaniswa nokufa okuhlukaniswayo.

2.2 Izinga lokushisa lesikhunta

Ngokusekelwe kulwazi lokukhiqiza endaweni, izinga lokushisa lesikhunta kufanele ligcinwe phakathi kuka-420-450°C. Izikhathi zokushisisa ngokweqile zingaholela ekugugulekeni kwesikhunta ngesikhathi sokusebenza. Ngaphezu kwalokho, ukubekwa kwesikhunta ngendlela efanele ngesikhathi sokushisa kubalulekile. Izibunjwa akufanele zihlanganiswe eduze kakhulu, zishiye isikhala phakathi kwazo. Ukuvimbela ukuphuma komoya kwesithando somlilo noma ukubekwa okungafanele kungaholela ekushiseni okungalingani kanye nokukhipha okungahambisani.

3 Isikhunta Factors

Idizayini yesikhunta, ukucubungula isikhunta, nokugcinwa kwesikhunta kubalulekile ekubunjweni kwe-extrusion futhi kuthinta ngokuqondile ikhwalithi yomkhiqizo, ukunemba kobukhulu, kanye nokusebenza kahle kokukhiqiza. Ukudweba izinqubo zokukhiqiza kanye nolwazi olwabiwe lwesakhiwo sesikhunta, ake sihlaziye lezi zici.

3.1 I-Mold Design

Isikhunta siyisisekelo sokwakheka komkhiqizo futhi sidlala indima ebalulekile ekunqumeni ukuma, ukunemba kobukhulu, ikhwalithi yendawo ephezulu, kanye nezakhiwo ezibonakalayo zomkhiqizo. Kumaphrofayili esikhunta anezimbotshana ezinezidingo eziphezulu, ukwenza ngcono ikhwalithi yendawo kungafinyelelwa ngokunciphisa inani lembobo ephambukisayo kanye nokwenza kahle ukubekwa kwamabhuloho okuphambukisa ukugwema indawo yokuhlobisa eyinhloko yephrofayela. Ukwengeza, uma kufa okuyisicaba, ukusebenzisa idizayini yomgodi wokugeleza obuyela emuva kungaqinisekisa ukugeleza kwensimbi efanayo emigodini yokufa.

3.2 Ukucubungula isikhunta

Ngesikhathi sokucubungula isikhunta, ukunciphisa ukumelana nokugeleza kwensimbi kumabhuloho kubalulekile. Ukugaya amabhuloho okuphambukisa kahle kuqinisekisa ukunemba kwezindawo zebhuloho lokuphambukisa futhi kusiza ukuzuza ukugeleza kwensimbi okufanayo. Kumaphrofayili anezidingo zekhwalithi ephezulu, njengamaphaneli elanga, cabanga ukwandisa ukuphakama kwegumbi lokushisela noma ukusebenzisa inqubo yesibili yokushisela ukuze uqinisekise imiphumela emihle yokushisela.

3.3 Ukugcinwa Kwesikhunta

Ukugcinwa kwesikhunta njalo kubalulekile ngokufanayo. Ukupholisha isikhunta nokusebenzisa ukugcinwa kwe-nitrogenization kungavimbela izinkinga ezifana nobulukhuni obungalingani ezindaweni zokusebenza zesikhunta.

4 Ikhwalithi Engenalutho

Ikhwalithi yokungenalutho inomthelela obalulekile kukhwalithi yendawo yomkhiqizo, ukusebenza kahle kwe-extrusion, kanye nokulimala kwesikhunta. Izikhala zekhwalithi ephansi zingaholela ezinkingeni zekhwalithi ezinjengama-grooves, ukushintsha umbala ngemva kwe-oxidation, kanye nempilo yesikhunta esincishisiwe. Ikhwalithi engenalutho ihlanganisa ukwakheka okufanele nokufana kwezinto, zombili ezithinta ngokuqondile ukuphuma kwe-extrusion kanye nekhwalithi yendawo.

4.1 Ukucushwa Kwesakhiwo

Ukuthatha amaphrofayili ephaneli yelanga njengesibonelo, ukumisa kahle kwe-Si, Mg, kanye ne-Fe ku-alloy ekhethekile engu-6063 ye-porous mold extrusion ibalulekile ukuze kuzuzwe ikhwalithi ephezulu ngaphandle kokuyekethisa izakhiwo zemishini. Inani eliphelele nengxenye ye-Si ne-Mg ibalulekile, futhi ngokusekelwe ekuhlangenwe nakho kokukhiqiza kwesikhathi eside, ukugcina i-Si+Mg ebangeni lika-0.82-0.90% kulungele ukuthola ikhwalithi yendawo efiselekayo.

Ekuhlaziyweni kwezikhala ezingahambelani namaphaneli elanga, kwatholakala ukuthi izakhi zokulandelela nokungcola kwakungazinzile noma kudlule imingcele, okuthinta kakhulu ikhwalithi yendawo. Ukwengezwa kwezakhi ngesikhathi se-alloying esitolo sokuncibilika kufanele kwenziwe ngokucophelela ukuze kugwenywe ukungazinzi noma ukweqisa kwezakhi zokulandelela. Esigabeni sokuhlukaniswa kwemfucuza, imfucuza ekhishwayo ihlanganisa imfucuza eyinhloko njengokusikeka kanye nezinto eziyisisekelo, imfucuza yesibili ihlanganisa imfucuza yangemva kokucubungula evela emisebenzini efana ne-oxidation kanye ne-powder coating, futhi amaphrofayili okufakwa okushisayo ahlukaniswa njengemfucuza ephakeme. Amaphrofayili ane-oxidized kufanele asebenzise okungenalutho okukhethekile, futhi ngokuvamile akukho mfucuza ezongezwa uma izinto zanele.

4.2 Inqubo Yokukhiqiza Engenalutho

Ukuze uthole izikhala zekhwalithi ephezulu, ukubambelela ngokuqinile ezimisweni zokucubungula zesikhathi sokuhlanzwa kwe-nitrogen nesikhathi sokumisa i-aluminium kubalulekile. Izakhi ze-alloying ngokuvamile zengezwa ngendlela ye-block, futhi ukuxuba okuphelele kusetshenziselwa ukusheshisa ukuqedwa kwazo. Ukuxuba okulungile kuvimbela ukwakheka kwezindawo zokugxila eziphezulu zendawo ze-alloy elements.

Isiphetho

Ama-alloys e-aluminium asetshenziswa kakhulu ezimotweni zamandla amasha, asetshenziswa ezingxenyeni zesakhiwo nezingxenye ezinjengomzimba, injini, namasondo. Ukwanda kokusetshenziswa kwama-alloys e-aluminium embonini yezimoto kuqhutshwa isidingo sokusebenza kahle kwamandla kanye nokusimama kwemvelo, kuhlanganiswe nentuthuko kubuchwepheshe be-aluminium alloy. Kumaphrofayili anezidingo zekhwalithi ephezulu, njengamathreyi ebhethri e-aluminium anezimbobo eziningi zangaphakathi kanye nezimfuno eziphezulu zokusebenza kwemishini, ukuthuthukisa ukusebenza kahle kwe-porous mold extrusion kubalulekile ukuze izinkampani ziphumelele kumongo wokuguqulwa kwamandla.

Ihlelwe nguMay Jiang evela kwaMAT Aluminium

Isikhathi sokuthumela: May-30-2024