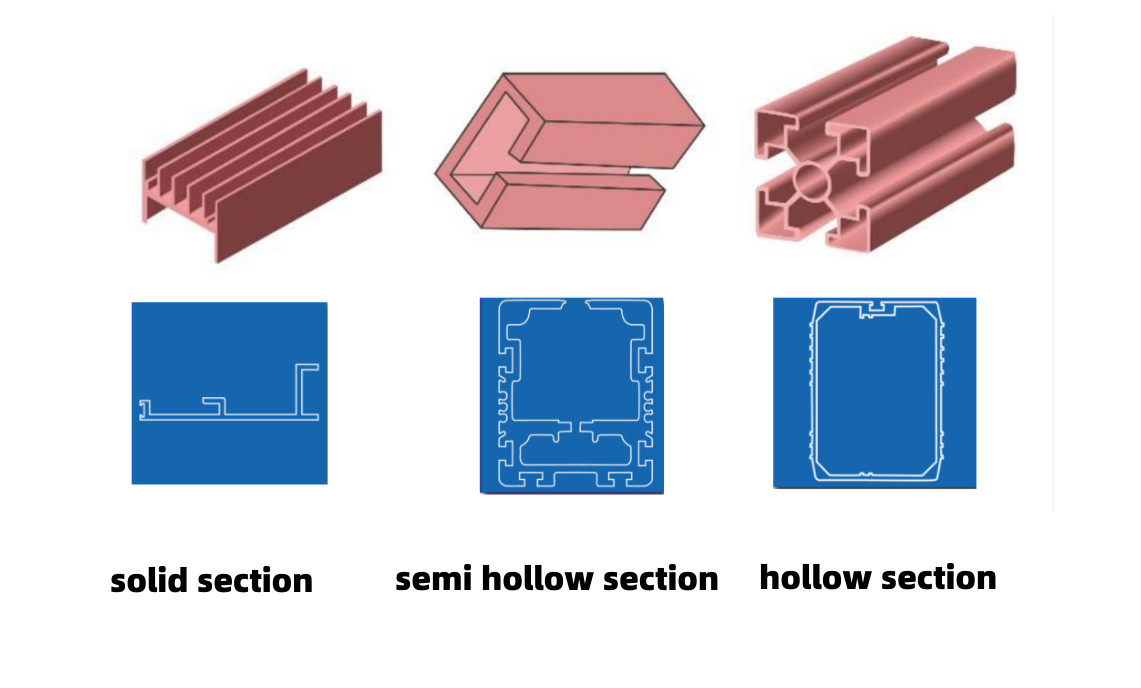

Ingxenye ye-aluminium extrusion ihlukaniswe izigaba ezintathu:

Isigaba esiqinile: izindleko eziphansi zomkhiqizo, izindleko zesikhunta eziphansi

Isigaba esingenalutho: isikhunta kulula ukusigqoka futhi sidabuke futhi siphuke, ngezindleko eziphezulu zomkhiqizo kanye nezindleko zesikhunta

Isigaba esingenalutho: izindleko zomkhiqizo eziphezulu kanye nezindleko zesikhunta, izindleko zesikhunta eziphakeme kakhulu zemikhiqizo enezimbotshana

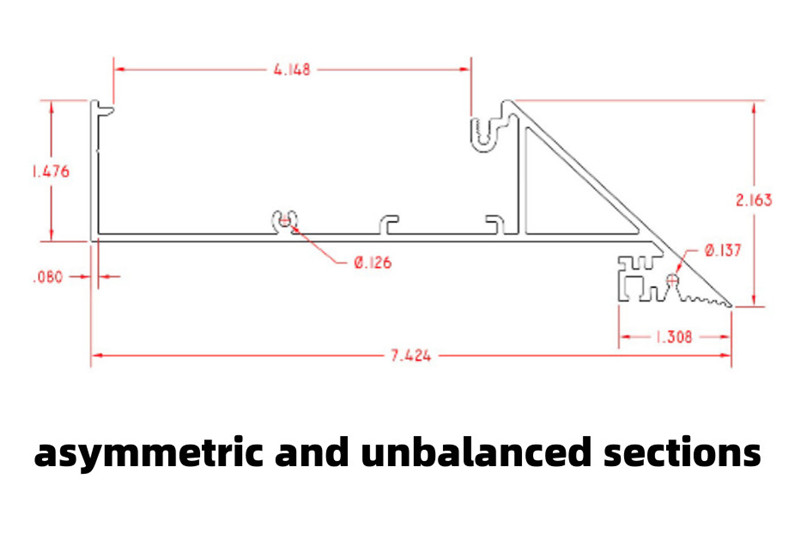

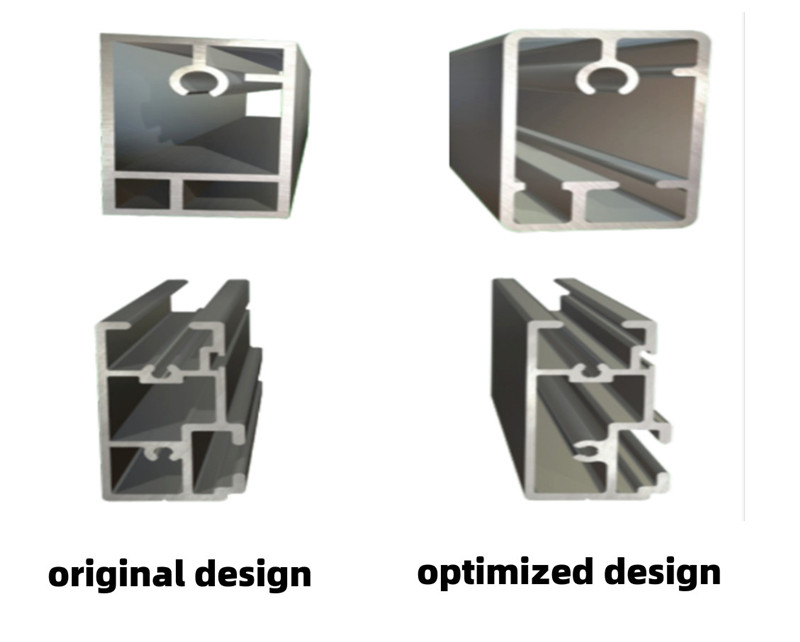

1.Gwema izigaba ezi-asymmetrical nezingalingani

Izingxenye ze-asymmetric nezingalingani zandisa ubunkimbinkimbi be-extrusion, futhi ngesikhathi esifanayo, izinkinga zekhwalithi zivame ukwenzeka, njengokunemba kwe-dimensional kanye ne-flatness kunzima ukuqinisekisa, ukukhothama nokusonteka kwezingxenye, ukusebenza kahle kokukhiqiza okuphansi, kanye nesikhunta kulula ukugqoka nokudiliza ngesikhathi sokukhiqiza ngobuningi.

I-asymmetric eyengeziwe noma ukungalingani kwesigaba se-aluminium extrusion, kuba nzima nakakhulu ukuqinisekisa ubuqotho, i-engeli nokunye ukunemba kobukhulu.

Nakuba amajamo a-asymmetrical futhi angalingani angakhiqizwa, insimbi mancane amathuba okuthi igeleze ezindaweni eziwumngcingo nezingajwayelekile ngesikhathi sokukhipha, lapho ukuhlanekezela noma ezinye izinkinga zekhwalithi zingenzeka kalula.

Futhi, ngisho noma kungenzeka ukukhipha ukubunjwa kwe-asymmetric nokungalingani, izindleko eziphezulu zamathuluzi kanye nezindleko zokukhiqiza eziphakeme ngenxa yesivinini esihamba kancane sokukhipha, ekugcineni kuholele ezindlekweni eziphezulu zokucubungula isikhunta kanye nezindleko zokukhiqiza.

Uma sikhulu isibalo sezinhlangothi namashaneli kuphrofayela ye-extrusion, izoba kancane inembe futhi ibize kakhulu.

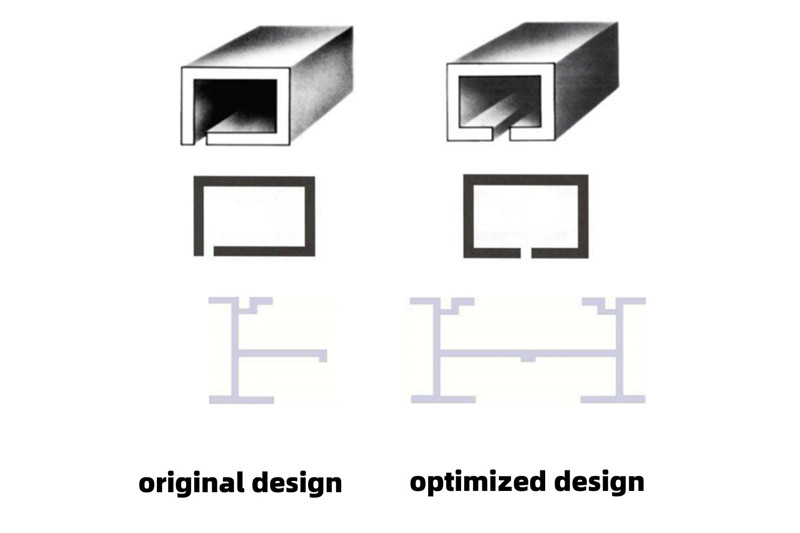

2.Ukuba lula komumo wesigaba, kuba ngcono

Abanye onjiniyela bomklamo womkhiqizo baklama izici eziningi kakhulu ku-extrusion ye-aluminium. Nakuba inzuzo eyingqayizivele ye-aluminium extrusions iwukwengeza izimbobo, izikhala noma abaphathi be-screw esigabeni, kuzoholela ekwakhiweni kwesikhunta esiyinkimbinkimbi kakhulu, noma okungeke kukhishwe nhlobo ngezindleko zokukhiqiza ezibiza kakhulu.

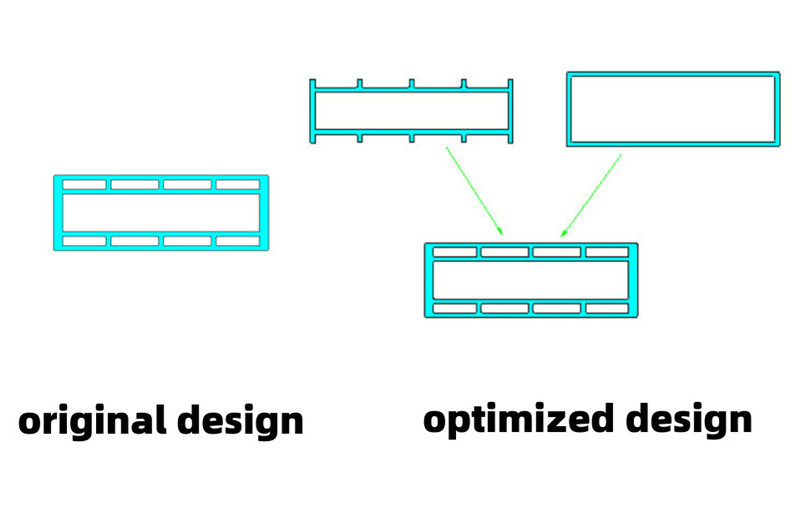

Uma ingxenye ye-extrusion iyinkimbinkimbi kakhulu, ingacatshangwa ukuthi isebenzise izingxenye ezimbili noma ngaphezulu ze-extrusion.

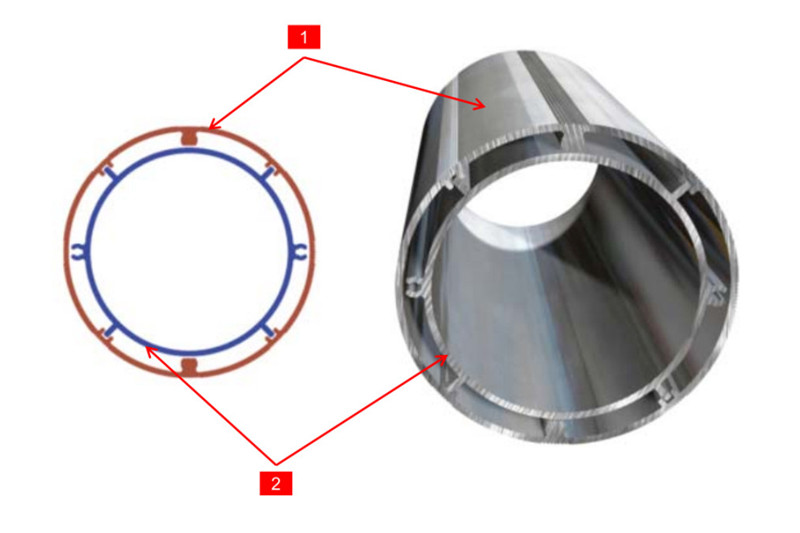

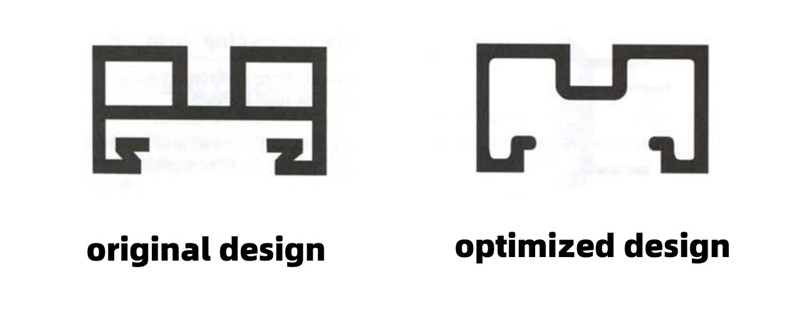

3.Isigaba esingenalutho esinezimbotshana silungiselelwe ukuba sibe nembobo eyodwa

Ngokulungisa ingxenye egobile enembobo ibe yimbobo eyodwa, ukwakheka kwesikhunta kungenziwa lula futhi izindleko zingagcinwa.

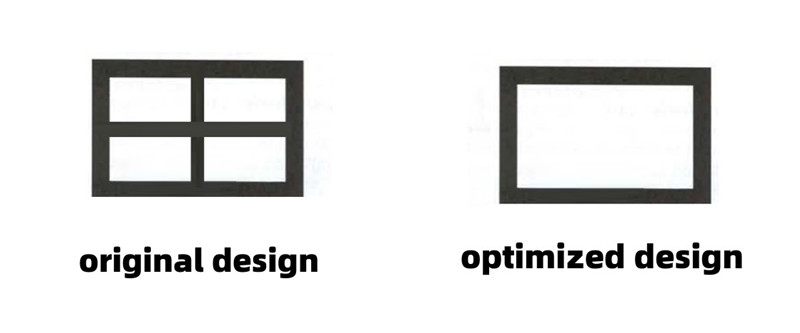

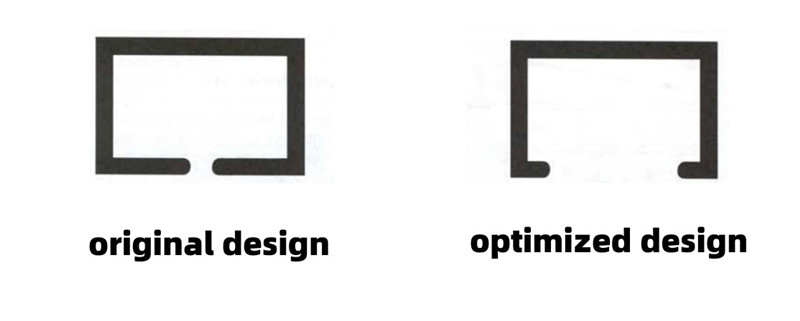

4.Isigaba esingenalutho sithuthukiswe ukuze sibe nengxenye engenalutho

Ngokwenza ingxenye engenalutho ibe ingxenye engenalutho, isakhiwo sesikhunta singenziwa lula futhi izindleko zingagcinwa.

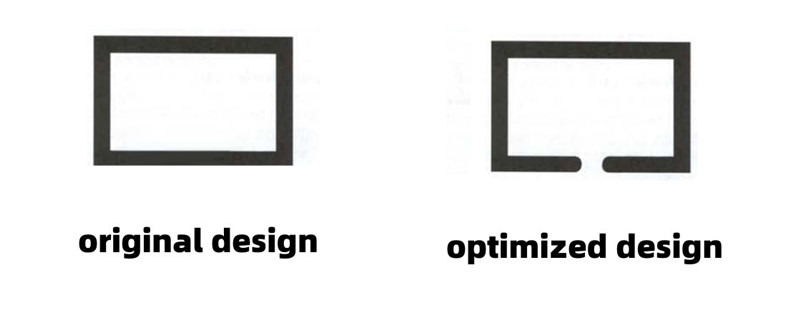

5.Ingxenye engenalutho ithuthukiswe yaba ingxenye eqinile

Ngokulungiselela isigaba esingenalutho sibe ingxenye eqinile, isakhiwo sesikhunta singenziwa lula futhi izindleko zingagcinwa.

6.Gwema ingxenye enezimbotshana

Izingxenye ezinama-porous zingathuthukiswa ngokuklama ukunciphisa izindleko zesikhunta kanye nobunzima ekucubunguleni nasekukhiqizeni.

Ihlelwe nguMay Jiang evela kwaMAT Aluminium

Jan. 16, 2023

Isikhathi sokuthumela: Feb-18-2023