Ukukhanya kwezimoto kuwumgomo okwabelwana ngawo wemboni yezimoto yomhlaba wonke. Ukwandisa ukusetshenziswa kwe-aluminium alloy materials ezingxenyeni zezimoto kuyisiqondiso sokuthuthukiswa kwezimoto zesimanje zohlobo olusha. I-6082 aluminium alloy ikwazi ukumelana nokushisa, iqiniswe ingxubevange ye-aluminium enamandla amaphakathi, ukwakheka okuhle kakhulu, ukushisela, ukumelana nokukhathala, nokumelana nokugqwala. Le alloy ingakhishwa ibe amapayipi, izinduku, kanye namaphrofayili, futhi isetshenziswa kabanzi ezingxenyeni zezimoto, izingxenye zesakhiwo ezishiselwe, ezokuthutha kanye nemboni yezokwakha.

Njengamanje, kunocwaningo olulinganiselwe lwe-aluminium alloy engu-6082 ezosetshenziswa ezimotweni zamandla amasha e-China. Ngakho-ke, lolu cwaningo lokuhlola luphenya imithelela yebanga lokuqukethwe kwento ye-aluminium engu-6082, amapharamitha wenqubo ye-extrusion, izindlela zokucisha, njll., ekusebenzeni kwephrofayela ye-alloy kanye ne-microstructure. Lolu cwaningo luhlose ukuthuthukisa ukwakheka kwengxubevange nokucubungula amapharamitha ukuze kukhiqizwe izinto ezisetshenziswayo ze-aluminium ezingama-6082 ezifanele izimoto zamandla amasha.

1. Izinto Zokuhlola kanye Nezindlela

Ukugeleza kwenqubo yokuhlola: Isilinganiso sokwakheka kwe-alloy - Ukuncibilika kwe-Ingot - I-ingot homogenization - I-Ingot sawing ibe amabhilidi - Ukukhishwa kwamaphrofayili - Ukucisha amaphrofayili emgqeni - Ukuguga okwenziwayo - Ukulungiswa kwezibonelo zokuhlola.

1.1 Ukulungiselela Ingot

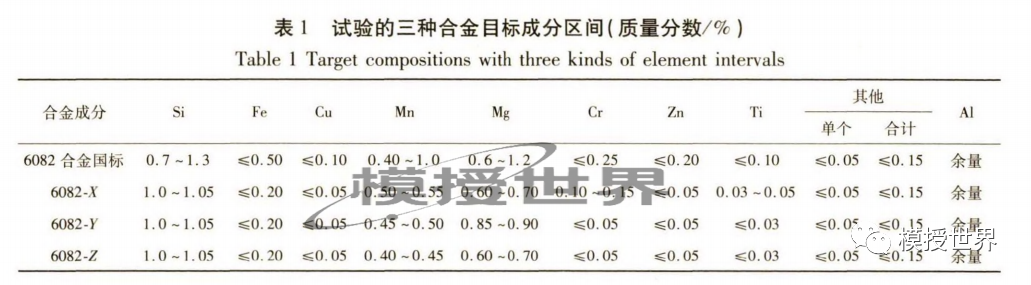

Phakathi kwebanga lamazwe ngamazwe lokuqanjwa kwengxube ye-aluminium engu-6082, izingoma ezintathu zikhethiwe ezinobubanzi obuncane bokulawula, obulebulwe ngokuthi 6082-/6082″, 6082-Z, nokuqukethwe kwe-elementi ye-Si efanayo. Okuqukethwe kwe-Mg element, y > z; Okuqukethwe kwesici, x > y > z; Cr, okuqukethwe kwe-elementi ye-Ti, x > y = z. Amanani aqondiwe wokuqamba ingxubevange ethile aboniswa kuThebula 1. Ukusakaza kwe-ingot kwenziwa kusetshenziswa indlela yokupholisa amanzi eqhubekayo kancane kancane, elandelwa ukwelashwa kwe-homogenization. Womathathu ama-ingots ahlanganiswe ngendlela efanayo kusetshenziswa uhlelo lwefekthri olusungulwe ku-560°C amahora angu-2 ngokupholisa inkungu yamanzi.

1.2 Ukwengezwa kwamaphrofayili

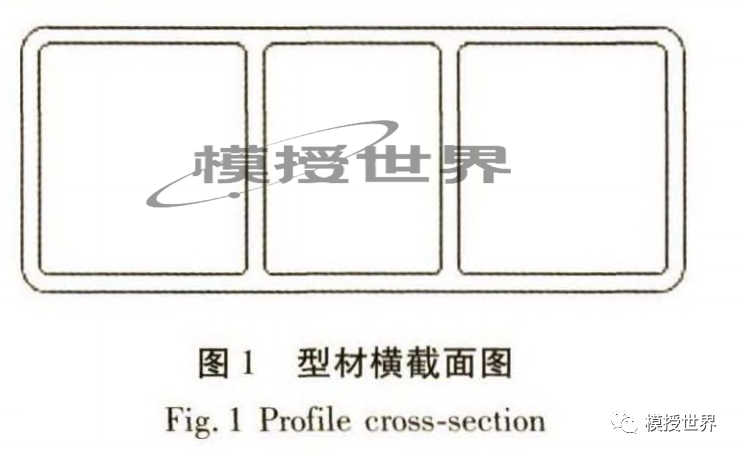

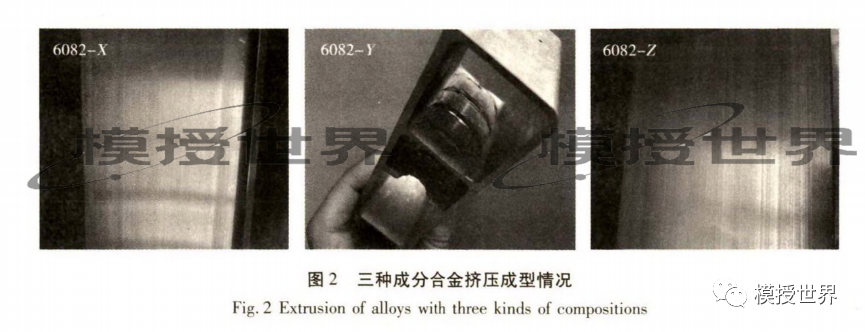

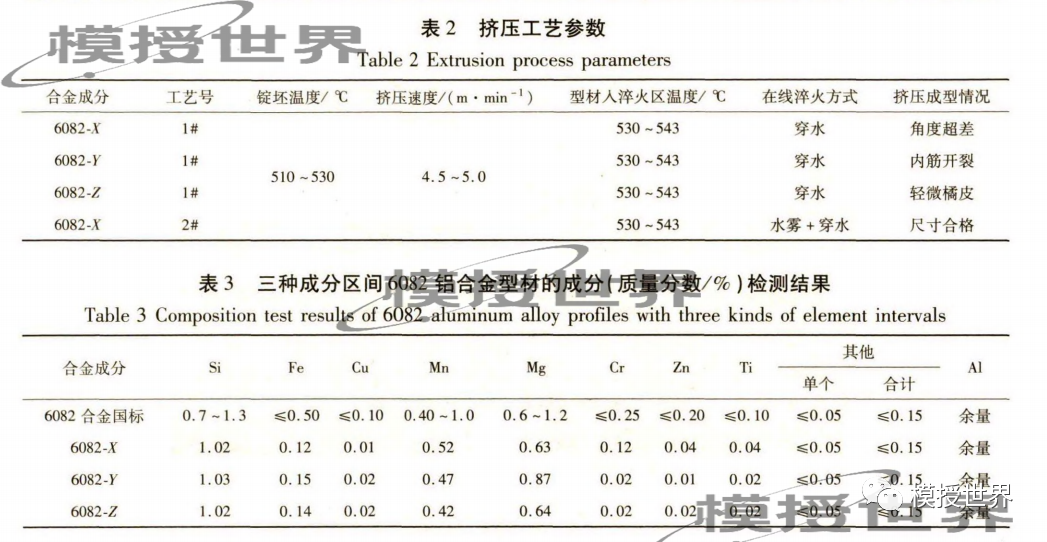

Amapharamitha wenqubo ye-extrusion alungiswa ngokufanele izinga lokushisa le-billet kanye nezinga lokupholisa lokucisha. I-cross-section yamaphrofayili akhishiwe ikhonjiswe kuMfanekiso 1. Imingcele yenqubo ye-extrusion ikhonjiswe kuThebula 2. Isimo sokwenza amaphrofayili akhishiwe siboniswe kuMfanekiso 2.

2.Imiphumela Yokuhlola Nokuhlaziya

Ukwakheka kwamakhemikhali okukhethekile kwamaphrofayela e-aluminium alloy angu-6082 phakathi kwezigaba ezintathu zokuqamba kwanqunywa kusetshenziswa i-spectrometer yokufunda eqondile ye-Swiss ARL, njengoba kuboniswe kuThebula 3.

2.1 Ukuhlolwa kokusebenza

Ukuze uqhathanise, ukusebenza kwamaphrofayili engxubevange yohlu oluthathu anezindlela ezihlukene zokucisha, amapharamitha afanayo we-extrusion, nezinqubo zokuguga kwahlolwa.

2.1.1 Ukusebenza Kwemishini

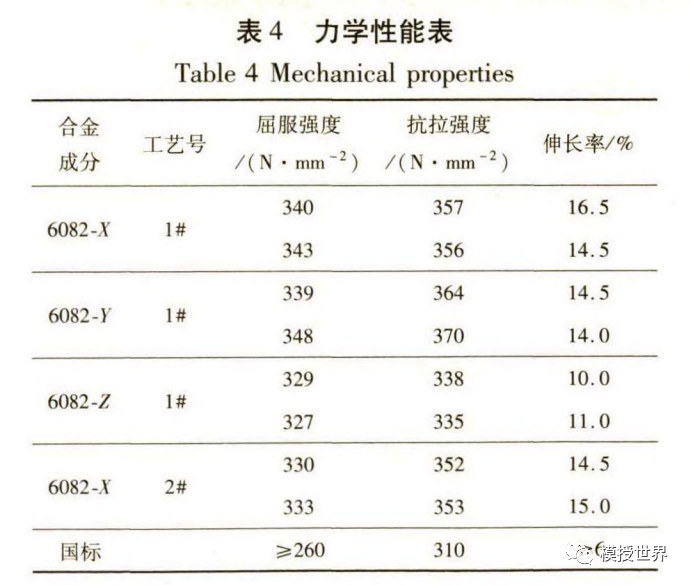

Ngemva kokuguga okwenziwayo ku-175°C amahora angu-8, izibonelo ezijwayelekile zathathwa lapho kukhishwa khona amaphrofayili ukuze kuhlolwe ukuqina kusetshenziswa umshini wokuhlola we-electronic we-Shimadzu AG-X100. Ukusebenza komshini ngemva kokuguga kokwenziwa kokuqanjwa okuhlukile nezindlela zokucisha kuboniswa kuThebula 4.

Kusukela kuThebula lesi-4, kungabonakala ukuthi ukusebenza kwemishini kwawo wonke amaphrofayili kudlula amanani ajwayelekile kazwelonke. Amaphrofayili akhiqizwe kusuka ku-6082-Z alloy billets abe nobude obuphansi ngemuva kokuphuka. Amaphrofayili akhiqizwe kusuka ku-6082-7 alloy billets ayenokusebenza okuphezulu kakhulu kwemishini. Amaphrofayili engxubevange angu-6082-X, anezindlela ezahlukene zesixazululo esiqinile, abonisa ukusebenza okuphezulu ngezindlela zokucisha ukupholisa okusheshayo.

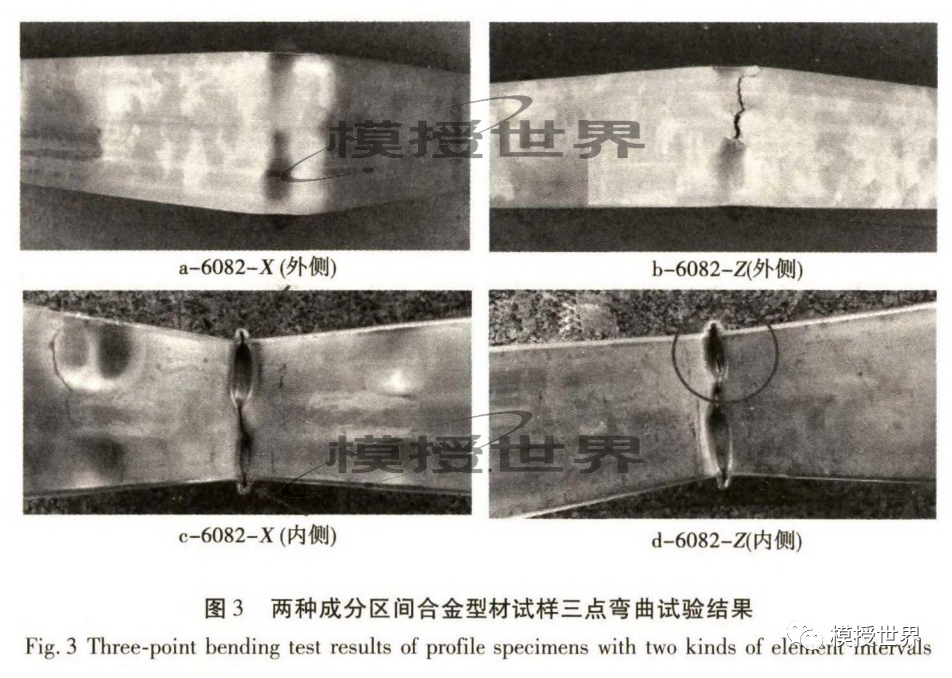

2.1.2 Ukuhlolwa Kokusebenza Okugoba

Kusetshenziswa umshini wokuhlola umhlaba wonke we-elekthronikhi, ukuhlolwa kokugoba okunamaphuzu amathathu kwenziwa kumasampula, futhi imiphumela yokugoba iboniswa kuMfanekiso 3. Umfanekiso 3 ubonisa ukuthi imikhiqizo ekhiqizwa kusukela ku-6082-Z alloy billets yayinekhasi eliqinile le-orange ebusweni kanye nokuqhekeka ngemuva kwamasampula agobile. Imikhiqizo ekhiqizwe kusukela ku-6082-X alloy billets ibe nokusebenza okungcono kakhulu kokugoba, izindawo ezibushelelezi ezingenalo ikhasi eliwolintshi, kanye nemifantu emincane kuphela ezindaweni ezikhawulelwe izimo zejiyomethri ngemuva kwamasampuli agobile.

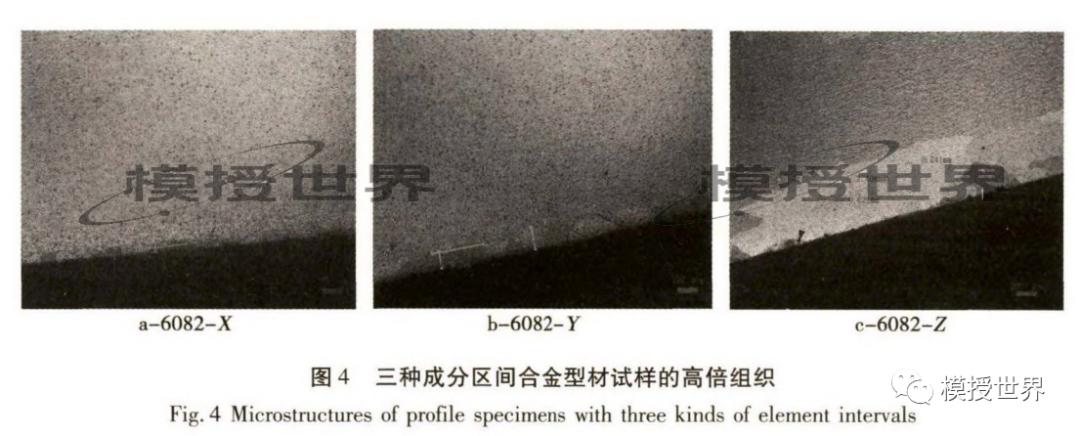

2.1.3 Ukuhlolwa Okuphakeme Kakhulu

Amasampula abonwa ngaphansi kwe-Carl Zeiss AX10 optical microscope yokuhlaziywa kwe-microstructure. Imiphumela yokuhlaziywa kwe-microstructure yamaphrofayili amathathu e-alloy yohla lokuqanjwa iboniswa kuMfanekiso 4. Umfanekiso 4 ubonisa ukuthi usayizi wohlamvu wemikhiqizo ekhiqizwe kusuka ku-6082-X rod kanye ne-6082-K ingxubevange billets yayifana, enosayizi ongcono kancane wokusanhlamvu ku-6082-X ingxubevange uma kuqhathaniswa ne-alloy engu-6082-y. Imikhiqizo ekhiqizwe kusuka ku-6082-Z alloy billets yayinosayizi abakhulu bokusanhlamvu kanye nezendlalelo ze-cortex ezishubile, eziholela kalula emakhasini awolintshi kanye nokwenza buthaka ukubopha kwensimbi kwangaphakathi.

2.2 Ukuhlaziywa Kwemiphumela

Ngokusekelwe emiphumeleni yokuhlola engenhla, kungaphethwa ngokuthi ukuklanywa kobubanzi bokwakheka kwe-alloy kuthinta kakhulu i-microstructure, ukusebenza, nokwakheka kwamaphrofayili akhishiwe. Okuqukethwe kwe-Mg ekhuphukile kunciphisa i-alloy plasticity futhi kuholele ekwakhekeni kwemifantu ngesikhathi sokukhipha. Okuqukethwe okuphezulu kwe-Mn, Cr, kanye ne-Ti kunomthelela omuhle ekucwengisiseni i-microstructure, yona ibe nomthelela omuhle kwikhwalithi yendawo, ukusebenza okugobayo, kanye nokusebenza kukonke.

3.Isiphetho

I-Mg element ithinta kakhulu ukusebenza komshini kwe-6082 aluminium alloy. Ukwanda kokuqukethwe kwe-Mg kunciphisa i-alloy plasticity futhi kuholela ekwakhekeni kwemifantu ngesikhathi sokukhipha.

I-Mn, Cr, kanye ne-Ti inomphumela omuhle ekuthuthukisweni kwe-microstructure, okuholela ekuthuthukisweni kwekhwalithi yendawo kanye nokusebenza okugobayo kwemikhiqizo ekhishwe.

Amandla okupholisa ahlukene okucisha anomthelela obonakalayo ekusebenzeni kwamaphrofayili e-aluminium alloy angu-6082. Ngokusetshenziswa kwezimoto, ukwamukela inqubo yokucisha inkungu yamanzi elandelwa ukupholisa isifutho samanzi kunikeza ukusebenza okungcono komshini futhi kuqinisekisa ukuma kwamaphrofayili nokunemba kobukhulu.

Ihlelwe nguMay Jiang evela kwaMAT Aluminium

Isikhathi sokuthumela: Mar-26-2024