Ngesikhathi senqubo ye-extrusion ye-aluminium alloy extruded materials, ikakhulukazi amaphrofayili e-aluminium, isici "somgodi" sivame ukwenzeka phezulu. Ukubonakaliswa okuqondile kufaka phakathi izimila ezincane kakhulu ezinokuminyana okuhlukahlukene, umsila, nokuzwakala kwesandla okusobala, okunomuzwa ohlabayo. Ngemuva kwe-oxidation noma ukwelashwa kwe-electrophoretic surface, kuvame ukuvela njengama-granules amnyama anamathela ebusweni bomkhiqizo.

Ekukhiqizeni i-extrusion yamaphrofayili esigaba esikhulu, lesi sici singenzeka kakhulu ngenxa yethonya lesakhiwo se-ingot, izinga lokushisa le-extrusion, isivinini se-extrusion, ubunzima besikhunta, njll. Iningi lezinhlayiya ezinhle zokukhubazeka kwe-pitted zingasuswa ngesikhathi senqubo yokulungiselela ubuso bephrofayili, ikakhulukazi inqubo ye-alkali etching, kuyilapho inani elincane lezinhlayiya ezinobukhulu obuncane zihlala endaweni eqinile yephrofayili, i-particle eqinile ehlala njalo ithinta ikhwalithi yokugcina. umkhiqizo.

Emikhiqizweni evamile yomnyango wesakhiwo kanye nephrofayela yefasitela, amakhasimende ngokuvamile amukela amaphutha amancane anemigodi, kodwa kumaphrofayela emboni adinga ukugcizelelwa okulinganayo kwezakhiwo zemishini nokusebenza kokuhlobisa noma ukugcizelelwa okwengeziwe kokusebenza kokuhlobisa, amakhasimende ngokuvamile awawamukeli lesi sici, ikakhulukazi amaphutha anemigodi angahambisani nombala ohlukile wangemuva.

Ukuze kuhlaziywe indlela yokwakheka kwezinhlayiya ezimahhadlahhadla, i-morphology kanye nokwakheka kwezindawo ezinesici ngaphansi kokuhlanganiswa kwe-alloy ehlukene kanye nezinqubo ze-extrusion zahlaziywa, futhi umehluko phakathi kokukhubazeka kanye ne-matrix kwaqhathaniswa. Isixazululo esizwakalayo sokuxazulula ngempumelelo izinhlayiya ezimaholoholo sabekwa phambili, futhi kwenziwa ukuhlolwa kwesilingo.

Ukuze uxazulule amaphutha emigodini yamaphrofayili, kuyadingeka ukuqonda indlela yokwakheka kweziphambeko zemigodi. Ngesikhathi senqubo yokukhishwa, i-aluminium enamathela ebhandeni lokusebenza yimbangela eyinhloko yokulimala kwe-pitting ebusweni bezinto ze-aluminium extruded. Lokhu kungenxa yokuthi inqubo ye-extrusion ye-aluminium yenziwa ekushiseni okuphezulu okungaba ngu-450°C. Uma imiphumela yokushisa kwe-deformation nokushisa kwe-friction yengezwa, izinga lokushisa lensimbi lizoba phezulu uma ligeleza liphuma emgodini wokufa. Lapho umkhiqizo ugeleza uphuma emgodini wokufa, ngenxa yokushisa okuphezulu, kukhona isenzakalo sokunamathela kwe-aluminium phakathi kwensimbi nebhande elisebenzayo lesikhunta.

Ifomu yalokhu kubopha ngokuvamile: inqubo ephindaphindiwe yokubopha - ukudabula - ukubopha - ukudabula futhi, futhi umkhiqizo ugeleza phambili, okuholela emigodini eminingi emincane ebusweni bomkhiqizo.

Lesi senzo sokubopha sihlobene nezici ezifana nekhwalithi ye-ingot, isimo esingaphezulu sebhande elisebenzayo lesikhunta, izinga lokushisa le-extrusion, isivinini se-extrusion, izinga lokuguquguquka, kanye nokumelana nokuguquguquka kwensimbi.

1 Izinto zokuhlola nezindlela

Ngocwaningo lokuqala, sifunde ukuthi izici ezifana nokuhlanzeka kwe-metallurgical, isimo sesikhunta, inqubo yokukhishwa, izithako, nezimo zokukhiqiza zingathinta izinhlayiya ezingaphezulu. Esivivinyweni, izinduku ezimbili ze-alloy, i-6005A ne-6060, zisetshenziselwa ukukhipha isigaba esifanayo. I-morphology kanye nokwakheka kwezikhundla zezinhlayiyana eziqinile kwahlaziywa ngokusebenzisa i-spectrometer yokufunda eqondile nezindlela zokuthola i-SEM, futhi kuqhathaniswa ne-matrix evamile ezungezile.

Ukuze uhlukanise ngokucacile i-morphology yeziphambeko ezimbili ze-pitted nezinhlayiya, zichazwa kanje:

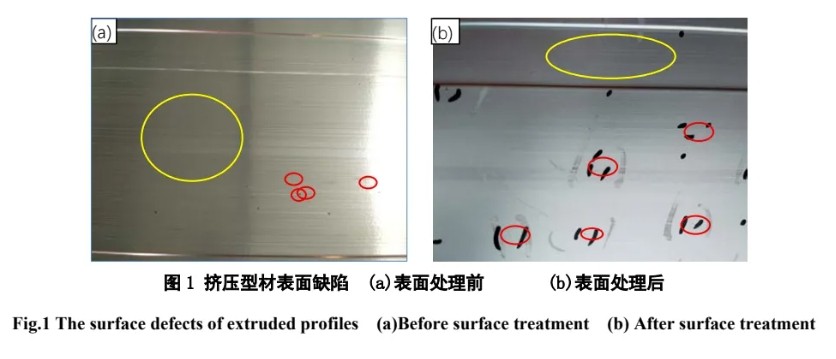

(1) Amaphutha emigodini noma amaphutha okudonsa kuwuhlobo oluthile lwesici esingajwayelekile esifana ne-tadpole noma isici esifana nephuzu esibonakala ebusweni bephrofayela. Isici siqala kusukela emugqeni wokuklwebha futhi sigcine ngokuthi isici siwe, sinqwabelana sibe ubhontshisi wensimbi ekugcineni komugqa wokuklwebha. Usayizi wesici esifakwe emgodini ngokuvamile ngu-1-5mm, futhi uphenduka ube mnyama mnyama ngemva kokwelashwa kwe-oxidation, okuthinta ekugcineni ukubukeka kwephrofayela, njengoba kukhonjisiwe kumbuthano obomvu kuMfanekiso 1.

(2) Izinhlayiya ezingaphezulu zibizwa nangokuthi ubhontshisi wensimbi noma izinhlayiya ze-adsorption. Ingaphezulu lephrofayili ye-aluminium alloy linamathiselwe ngezinhlayiya zensimbi eqinile ezimpunga-omnyama futhi linesakhiwo esixekethile. Kunezinhlobo ezimbili zamaphrofayili e-aluminium alloy: lawo angasulwa nalawo angeke asulwe. Ubukhulu ngokuvamile bungaphansi kuka-0.5mm, futhi buzwakala bulukhuni uma uthintwa. Akukho ukuklwebheka engxenyeni engaphambili. Ngemuva kwe-oxidation, ayihlukile kakhulu ku-matrix, njengoba kukhonjisiwe kumbuthano ophuzi kuMfanekiso 1.

2 Imiphumela yokuhlolwa nokuhlaziya

2.1 Amaphutha okudonsa ebusweni

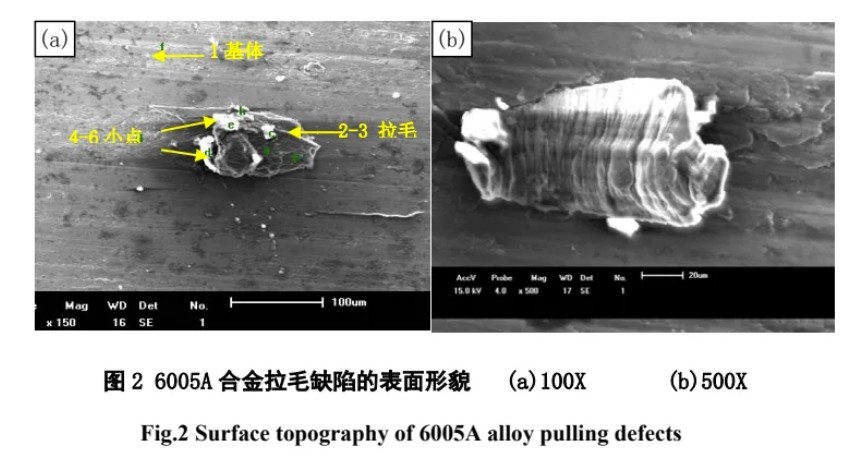

Umfanekiso wesi-2 ubonisa i-microstructural morphology yesici sokudonsa ebusweni be-alloy engu-6005A. Kukhona imihuzuko efana nesinyathelo engxenyeni engaphambili yokudonsa, futhi igcina ngamaqhuqhuva astakiwe. Ngemva kokuvela kwamaqhuqhuva, ingaphezulu libuyela kokujwayelekile. Indawo yesici esiqinile ayibushelelezi uma uthintwa, inomuzwa obukhali wameva, futhi inamathela noma inqwabelana ebusweni bephrofayela. Ngokuhlolwa kwe-extrusion, kwaphawulwa ukuthi i-morphology yokudonsa ye-6005A kanye ne-6060 yamaphrofayili e-extruded iyafana, futhi ukuphela komsila womkhiqizo kungaphezu kokuphela kwekhanda; umehluko ukuthi usayizi wokudonsa jikelele we-6005A mncane futhi ukujula kokuklwebheka kubuthakathaka. Lokhu kungase kuhlotshaniswe nezinguquko ekubunjweni kwe-alloy, isimo se-cast rod, nezimo zesikhunta. Uma kubhekwa ngaphansi kwe-100X, kunamamaki okuklwebha asobala ekugcineni kwendawo edonsayo, enwetshiwe eduze kwe-extrusion direction, futhi ukwakheka kwezinhlayiya zokugcina ze-nodule akujwayelekile. Ku-500X, ingemuva elingaphambili lendawo edonsayo linemihuzuko efana nesinyathelo eduze kwe-extrusion direction (usayizi walesi sici cishe u-120 μm), futhi kukhona izimpawu zokupakisha ezicacile ezinhlayiyeni ze-nodular ekugcineni komsila.

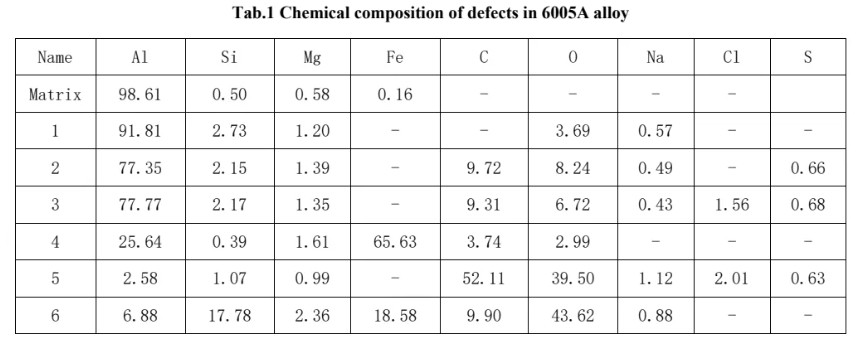

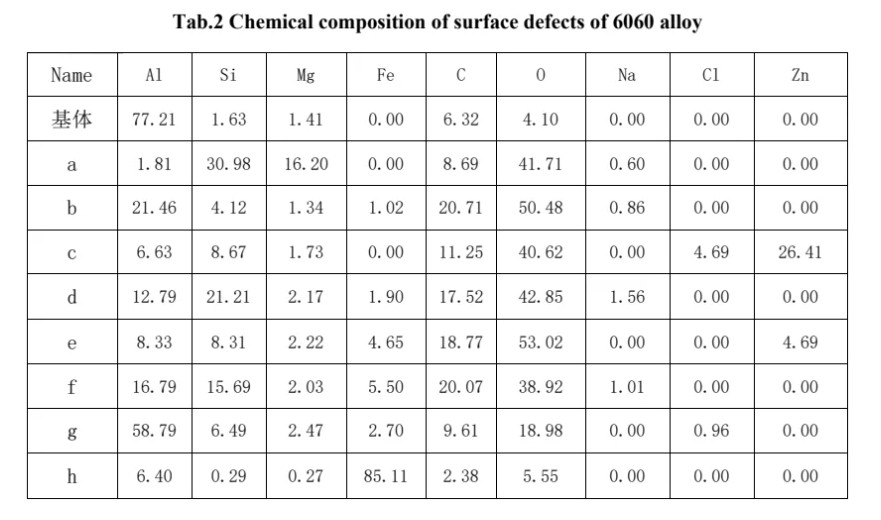

Ukuze kuhlaziywe izimbangela zokudonsa, i-spectrometer yokufunda eqondile kanye ne-EDX yasetshenziselwa ukwenza ukuhlaziya kwengxenye ezindaweni ezinesici kanye ne-matrix yezingxenye ezintathu ze-alloy. Ithebula 1 libonisa imiphumela yokuhlolwa yephrofayela ye-6005A. Imiphumela ye-EDX ibonisa ukuthi ukwakheka kwendawo yokunqwabelanisa yezinhlayiya ezidonsayo ngokuyisisekelo kufana nalokho kwe-matrix. Ngaphezu kwalokho, ezinye izinhlayiya zokungcola okuhle zinqwabelana ngaphakathi naseduze kwesici sokudonsa, futhi izinhlayiya zokungcola ziqukethe u-C, O (noma Cl), noma u-Fe, Si, no-S.

Ukuhlaziywa kokukhubazeka okuqinile kwamaphrofayili angu-6005A ane-oxidized extruded kubonisa ukuthi izinhlayiya ezidonsayo zinkulu ngosayizi (1-5mm), indawo engaphezulu igcwele, futhi kunemihuzuko efana nesinyathelo engxenyeni engaphambili; Ukwakheka kuseduze ne-Al matrix, futhi kuzoba nezigaba ezahlukahlukene eziqukethe u-Fe, u-Si, u-C, no-O ezisatshalaliswa kuyo. Kubonisa ukuthi indlela yokwakheka edonsayo yama-alloys amathathu iyafana.

Phakathi nenqubo ye-extrusion, ukungqubuzana kokugeleza kwensimbi kuzobangela ukuthi izinga lokushisa lebhande elisebenzayo lesikhunta likhuphuke, lenze "ungqimba lwe-aluminium olunamathelayo" emaphethelweni okusika okungena kwebhande lokusebenza. Ngesikhathi esifanayo, i-Si eyeqile nezinye izakhi ezifana ne-Mn no-Cr ku-aluminium alloy kulula ukwakha izixazululo eziqinile ezishintshayo nge-Fe, ezokhuthaza ukwakheka "kwesendlalelo se-aluminium enamathelayo" ekungeneni kwendawo yokusebenza yesikhunta.

Njengoba insimbi igeleza iye phambili futhi igudla ibhande lomsebenzi, into ephindaphindayo yokubopha-ukuklebhula-bonding eqhubekayo kwenzeka endaweni ethile, okubangela ukuthi insimbi iqhubekele phezulu kulesi sikhundla. Lapho izinhlayiya zanda zibe usayizi othize, Izodonswa umkhiqizo ogelezayo futhi zenze izimpawu zokuklwebheka endaweni yensimbi. Izohlala phezu kwensimbi futhi yakha izinhlayiya ezidonsa ekupheleni kokubhala. ngakho-ke, kungacatshangwa ukuthi ukwakheka kwezinhlayiya eziqinile kuhlobene ngokuyinhloko ne-aluminium enamathela ebhande elisebenzayo lesikhunta. Izigaba ezihlukene ezisatshalaliswa eduze kwayo zingase zisuka kuwoyela wokugcoba, ama-oxides noma izinhlayiya zothuli, kanye nokungcola okulethwa indawo emangelengele ye-ingot.

Kodwa-ke, inani lokudonsa emiphumeleni yokuhlolwa ye-6005A lincane futhi neziqu zilula. Ngakolunye uhlangothi, kungenxa ye-chamfering ekuphumeni kwebhande elisebenzayo lesikhunta kanye nokupholishwa ngokucophelela kwebhande lokusebenza ukunciphisa ukushuba kongqimba lwe-aluminium; ngakolunye uhlangothi, ihlobene nokuqukethwe kwe-Si okweqile.

Ngokusho kwemiphumela yokwakheka kwe-spectral eqondile yokufunda, kungabonakala ukuthi ngaphezu kwe-Si ehlanganiswe ne-Mg Mg2Si, i-Si esele ivela ngesimo sento elula.

2.2 Izinhlayiya ezincane ebusweni

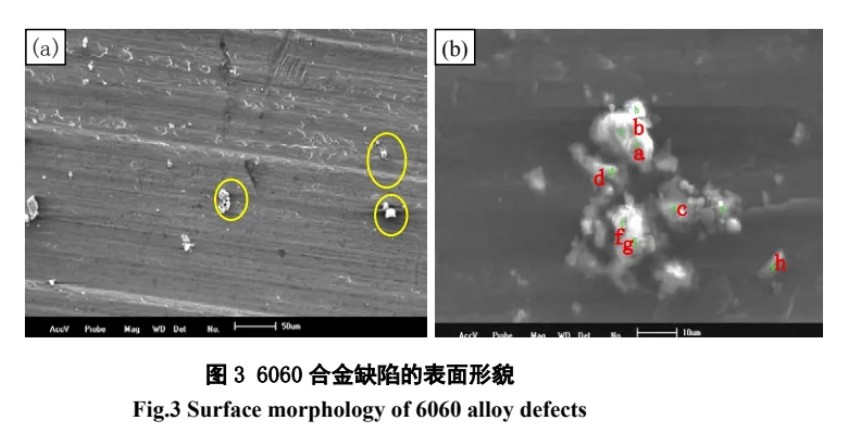

Ngaphansi kokuhlolwa okubonakalayo kokukhulisa okuphansi, izinhlayiya zincane (≤0.5mm), azisheleli lapho uthintwa, zinomuzwa obukhali, futhi zinamathela ebusweni bephrofayela. Uma kubhekwa ngaphansi kwe-100X, izinhlayiya ezincane ezingaphezulu zisakazwa ngokungahleliwe, futhi kunezinhlayiya ezinosayizi omncane ezinamathiselwe phezulu kungakhathaliseki ukuthi kukhona imihuzuko noma cha;

Ku-500X, kungakhathaliseki ukuthi kukhona ukuklwebheka okufana nesinyathelo endaweni eduze kwendlela ye-extrusion, izinhlayiya eziningi zisanamathiselwe, nosayizi bezinhlayiyana bayahluka. Ubukhulu bezinhlayiyana ezinkulu bungaba ngu-15 μm, kanti izinhlayiya ezincane zingaba ngu-5 μm.

Ngokuhlaziya ukwakheka kwezinhlayiya ezingaphezulu kwe-alloy engu-6060 kanye ne-matrix eqinile, izinhlayiya zakhiwe ngokuyinhloko yi-O, C, Si, ne-Fe, kanti okuqukethwe kwe-aluminium kuphansi kakhulu. Cishe zonke izinhlayiya ziqukethe izakhi ze-O no-C. Ukwakheka kwezinhlayiyana ngayinye kuhluke kancane. Phakathi kwazo, izinhlayiya zisondele ku-10 μm, ephakeme kakhulu kune-matrix Si, Mg, no-O; Ngezinhlayiya ezingu-c, u-Si, O, no-Cl ngokusobala aphakeme; Izinhlayiya u-d no-f ziqukethe u-Si, O, no-Na ophezulu; izinhlayiya e ziqukethe i-Si, Fe, kanye no-O; h izinhlayiya ziyizinhlanganisela eziqukethe i-Fe. Imiphumela yezinhlayiya ze-6060 ifana nalokhu, kodwa ngenxa yokuthi okuqukethwe kwe-Si ne-Fe ku-6060 ngokwayo kuphansi, okuqukethwe kwe-Si no-Fe okuhambisanayo ezinhlayiyeni ezingaphezulu nakho kuphansi; okuqukethwe kwe-C ezinhlayiyeni ezingu-6060 kuphansi kakhulu.

Izinhlayiya ezingaphezulu zingase zingabi yizinhlayiyana ezincane, kodwa zingase zibe khona ngendlela yokuhlanganisa izinhlayiya eziningi ezincane ezinomumo ohlukene, futhi amaphesenti obuningi bezakhi ezihlukene ezinhlayiyeni ezihlukahlukene ziyahlukahluka. Kukholakala ukuthi izinhlayiya ikakhulukazi zakhiwe izinhlobo ezimbili. Eyodwa imvula efana ne-AlFeSi kanye ne-elemental Si, esukela ezigabeni zokungcola kwendawo ephezulu yokuncibilika njenge-FeAl3 noma i-AlFeSi(Mn) ku-ingot, noma izigaba zokwehla ngesikhathi senqubo yokukhipha. Enye indaba yangaphandle enamathelayo.

2.3 Umthelela wobunzima obungaphezulu be-ingot

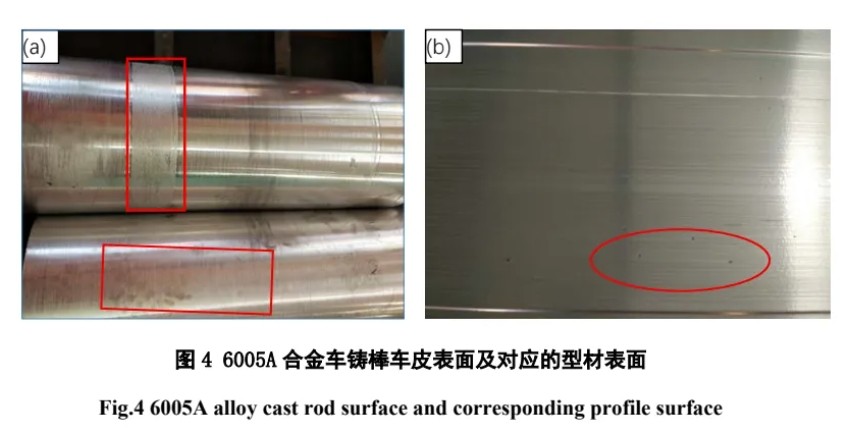

Ngesikhathi sokuhlolwa, kwatholakala ukuthi indawo engemuva ye-6005A cast rod lathe yayimahhadla futhi inothuli. Kwakukhona izinti ezimbili ezikhonjiwe ezinamamaki wamathuluzi ajikisayo ajule kakhulu ezindaweni zasendaweni, ezihambisana nokwanda okuphawulekayo kwenani lokudonsa ngemva kokukhishwa, futhi usayizi wokudonsa okukodwa wawumkhulu, njengoba kuboniswe kuMfanekiso 7.

I-cast rod engu-6005A ayinayo i-lathe, ngakho-ke ubulukhuni obungaphezulu buphansi futhi nenani lokudonsa liyancipha. Ngaphezu kwalokho, njengoba kungekho uketshezi olunqunyiwe oluningi olunamathiselwe kumamaki we-lathe we-cast rod, okuqukethwe kwe-C ezinhlayiyeni ezihambisanayo kuyancishiswa. Kufakazelwa ukuthi amamaki aphendukayo ebusweni benduku ephonswe azokwandisa ukudonsa nokwakheka kwezinhlayiyana ngezinga elithile.

3 Ingxoxo

(1) Izingxenye zokukhubazeka kokudonsa ziyafana nalezo ze-matrix. Yizinhlayiya zangaphandle, isikhumba esidala ebusweni be-ingot nokunye ukungcola okuqoqwe odongeni lombhobho we-extrusion noma indawo efile yesikhunta ngesikhathi senqubo ye-extrusion, ezilethwa endaweni yensimbi noma ungqimba lwe-aluminium webhande elisebenzayo lesikhunta. Njengoba umkhiqizo ugeleza uye phambili, kubangwa imihuzuko engaphezulu, futhi lapho umkhiqizo unqwabelanisa usayizi othile, ukhishwa umkhiqizo ukuze wenze ukudonsa. Ngemva kwe-oxidation, ukudonsa kwagqwala, futhi ngenxa yobukhulu bayo obukhulu, kwakukhona ukukhubazeka okufana nomgodi lapho.

(2) Izinhlayiya ezingaphezulu kwesinye isikhathi zivela njengezinhlayiya ezincane ezikodwa, futhi kwesinye isikhathi ziba khona ngendlela ehlanganisiwe. Ukwakheka kwazo ngokusobala kuhlukile kulokho kwe-matrix, futhi ikakhulukazi iqukethe izakhi ze-O, C, Fe, kanye ne-Si. Ezinye zezinhlayiya zibuswa izakhi zika-O no-C, kanti ezinye izinhlayiya zibuswa u-O, C, Fe, no-Si. Ngakho-ke, kucatshangwa ukuthi izinhlayiya ezingaphezulu zivela emithonjeni emibili: enye i-precipitates efana ne-AlFeSi kanye ne-elemental Si, futhi ukungcola okufana no-O no-C kunamathele phezulu; Enye indaba yangaphandle enamathelayo. Izinhlayiya ziyagqwala ngemva kwe-oxidation. Ngenxa yobukhulu bawo obuncane, azinawo noma umthelela omncane ebusweni.

(3) Izinhlayiya ezinothe ngama-elementi C no-O ngokuyinhloko zivela kuwoyela wokugcoba, uthuli, inhlabathi, umoya, njll. ezinamathele ngaphezu kwengot. Izingxenye eziyinhloko zamafutha okugcoba yi-C, O, H, S, njll., futhi ingxenye eyinhloko yothuli nomhlabathi yi-SiO2. Okuqukethwe kwezinhlayiya ezingaphezulu kwe-O ngokuvamile kuphezulu. Ngenxa yokuthi izinhlayiya zisesimweni sokushisa okuphezulu ngokushesha ngemva kokushiya ibhande lokusebenza, futhi ngenxa yendawo enkulu ethize yendawo yezinhlayiya, zikhanga kalula ama-athomu e-O emoyeni futhi zenze i-oxidation ngemva kokuxhumana nomoya, okuholela ekutheni okuqukethwe kwe-O ephakeme kune-matrix.

(4) I-Fe, i-Si, njll ikakhulukazi ivela kuma-oxides, isikali esidala kanye nezigaba zokungcola ku-ingot (iphuzu eliphakeme lokuncibilika noma isigaba sesibili esingaqediwe ngokugcwele yi-homogenization). Isici se-Fe sisuka ku-Fe kuma-ingots e-aluminium, sakha izigaba zokungcola okuncibilika okuphezulu njenge-FeAl3 noma i-AlFeSi(Mn), engakwazi ukuncibilika kusixazululo esiqinile phakathi nenqubo ye-homogenization, noma engaguquki ngokugcwele; I-Si ikhona ku-aluminium matrix ngesimo se-Mg2Si noma isixazululo esiqinile se-Si phakathi nenqubo yokuphonsa. Ngesikhathi senqubo yokushisa eshisayo ye-cast rod, i-Si eyeqile ingase idle. Ukunyibilika kwe-Si ku-aluminium ngu-0.48% ku-450°C no-0.8% (wt%) ku-500°C. Okuqukethwe okweqile kwe-Si ngo-6005 kucishe kube ngu-0.41%, futhi i-Si emisiwe ingase ibe ukuhlanganisa kanye nemvula ebangelwa ukushintshashintsha kokugxilisa ingqondo.

(5) I-Aluminium enamathela ebhandeni lokusebenza lesikhunta iyimbangela eyinhloko yokudonsa. I-extrusion die iyindawo enezinga eliphezulu lokushisa kanye nengcindezi ephezulu. I-Metal flow friction izokwandisa izinga lokushisa kwebhande elisebenzayo lesikhunta, okwenza "ungqimba lwe-aluminium olunamathelayo" emaphethelweni okusika okungena kwebhande lokusebenza.

Ngesikhathi esifanayo, i-Si eyeqile nezinye izakhi ezifana ne-Mn no-Cr ku-aluminium alloy kulula ukwakha izixazululo eziqinile ezishintshayo nge-Fe, ezokhuthaza ukwakheka "kwesendlalelo se-aluminium enamathelayo" ekungeneni kwendawo yokusebenza yesikhunta. Insimbi egeleza "kusendlalelo se-aluminium enamathelayo" ingeyokungqubuzana kwangaphakathi (i-shear eshelelayo ngaphakathi kwensimbi). Insimbi iyakhubazeka futhi iqine ngenxa yokungqubuzana kwangaphakathi, okukhuthaza insimbi engaphansi kanye nesikhunta ukuthi sinamathele ndawonye. Ngesikhathi esifanayo, ibhande elisebenzayo lesikhunta likhubazekile libe yisimo secilongo ngenxa yokucindezela, futhi i-aluminium enamathelayo eyakhiwe ingxenye enqenqemeni yebhande elisebenzayo elithinta iphrofayili ifana nokusika kwethuluzi lokuguqula.

Ukwakhiwa kwe-aluminium enamathelayo kuyinqubo eguquguqukayo yokukhula nokuchithwa. Izinhlayiya zihlale zikhishwa iphrofayili.Namathela ebusweni bephrofayili, wenze iziphambeko zokudonsa. Uma igeleza iphuma ngokuqondile ebhandeni lomsebenzi futhi ikhangiswe ngaso leso sikhathi ebusweni bephrofayili, izinhlayiya ezincane ezinamathele ngokushisa kwamanzi zibizwa ngokuthi "izinhlayiya ze-adsorption". Uma ezinye izinhlayiya zizophulwa yi-alloy aluminium extruded, ezinye izinhlayiya zizonamathela ebusweni bebhande lomsebenzi lapho zidlula ibhande lomsebenzi, zibangele imihuzuko ebusweni bephrofayela. Ukuphela komsila yi-matrix ye-aluminium estakiwe. Uma kune-aluminium eningi enamathele phakathi kwebhande lomsebenzi (isibopho siqinile), izokwandisa ukuklwebheka kwendawo.

(6) Isivinini sokukhipha isisu sinethonya elikhulu ekudonseni. Umthelela wejubane le-extrusion. Ngokuphathelene ne-alloy engu-6005 elandelwayo, isivinini sokukhipha siyakhuphuka phakathi kwebanga lokuhlola, izinga lokushisa eliphumayo liyakhuphuka, kanye nenani lezinhlayiya ezidonsa phezulu liyakhuphuka futhi liba nzima njengoba imigqa yomshini ikhula. Ijubane le-extrusion kufanele ligcinwe lizinzile ngangokunokwenzeka ukuze kugwenywe izinguquko ezisheshayo ngesivinini. Isivinini sokukhipha ngokweqile kanye nezinga lokushisa eliphakeme lokuphuma kuzoholela ekwenyukeni kokungqubuzana nokudonsa kwezinhlayiyana ezingathi sína. Indlela eqondile yomthelela wesivinini se-extrusion kwinto yokudonsa idinga ukulandelela nokuqinisekisa okulandelayo.

(7) Ikhwalithi ephezulu yenduku ekhonjiwe nayo iyisici esibalulekile esithinta izinhlayiya ezidonsayo. Ingaphezulu lenduku ekhonjiwe lukhuni, linama-sawing burrs, amabala kawoyela, uthuli, ukugqwala, njll., konke okwandisa ukuthambekela kokudonsa izinhlayiya.

4 Isiphetho

(1) Ukwakheka kweziphambeko zokudonsa kuhambisana nalokho kwe-matrix; ukwakheka kwendawo yezinhlayiyana ngokusobala kuhlukile kulokho kwe-matrix, ikakhulukazi equkethe izakhi ze-O, C, Fe, kanye ne-Si.

(2) Ukudonsa ukukhubazeka kwezinhlayiyana kubangelwa ikakhulukazi i-aluminium enamathela ebhande elisebenzayo lesikhunta. Noma yiziphi izici ezikhuthaza ukunamathela kwe-aluminium ebhandeni lokusebenza lesikhunta kuzodala amaphutha okudonsa. Ngokwesisekelo sokuqinisekisa ikhwalithi yenduku ekhonjiwe, ukukhiqizwa kwezinhlayiya ezidonsayo akunawo umthelela oqondile ekwakhiweni kwe-alloy.

(3) Ukwelashwa komlilo ngendlela efanele kunenzuzo ekunciphiseni ukudonsa kwendawo.

Isikhathi sokuthumela: Sep-10-2024