Ugqinsi olukhulu lwe-aluminium 6061T6 ingxubevange ye-aluminium idinga ukucishwa ngemuva kokukhishwa okushisayo. Ngenxa yomkhawulo we-extrusion engapheli, ingxenye yephrofayela izongena endaweni yokupholisa amanzi ngokulibaziseka. Uma i-ingot elandelayo emfushane iqhubeka nokukhishwa, le ngxenye yephrofayela izocisha ukubambezeleka. Indlela yokubhekana nendawo yokucisha ebambezelekile wudaba okufanele yonke inkampani yokukhiqiza ilubhekisise. Lapho imfucuza yenqubo yomsila we-extrusion imfushane, amasampula okusebenza athathiwe ngezinye izikhathi ayafaneleka futhi ngezinye izikhathi awafaneleki. Lapho kwenziwa isampula kabusha ohlangothini, ukusebenza kuyafaneleka futhi. Lesi sihloko sinikeza incazelo ehambisanayo ngokuhlolwa.

1. Izinto zokuhlola nezindlela

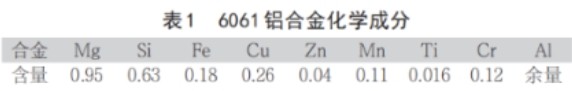

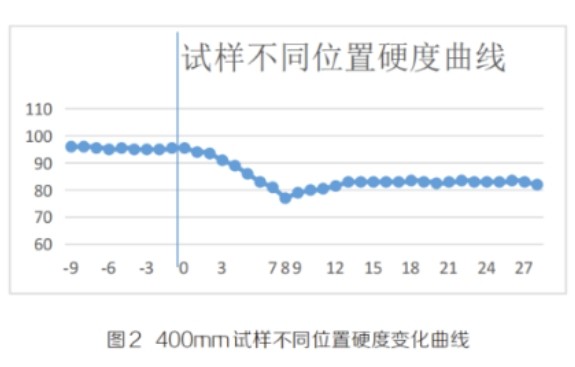

Izinto ezisetshenziswe kulokhu kuhlolwa yi-6061 aluminium alloy. Ukwakheka kwamakhemikhali ayo okukalwa ngokuhlaziywa kwe-spectral kungokulandelayo: Ihambisana ne-GB/T 3190-1996 international 6061 aluminium alloy composition standard.

Kulesi sivivinyo, ingxenye yephrofayili ekhishiwe yathathwa ukuze ithole ukwelashwa kwesixazululo esiqinile. Iphrofayili engu-400mm ubude yayihlukaniswe izingxenye ezimbili. Indawo 1 ipholiswe ngamanzi futhi yacishwa. I-Area 2 ipholiswe emoyeni imizuzwana engu-90 bese ipholiswa ngamanzi. Umdwebo wokuhlola uboniswa kuMfanekiso 1.

Iphrofayela ye-aluminium engu-6061 esetshenziswe kulokhu kuhlolwa ikhishwe i-extruder engu-4000UST. Izinga lokushisa lesikhunta liyi-500 ° C, izinga lokushisa lenduku yokuphonsa ngu-510 ° C, izinga lokushisa le-extrusion liyi-525 ° C, isivinini se-extrusion singu-2.1mm / s, ukupholisa kwamanzi okunamandla aphezulu kusetshenziswa ngesikhathi senqubo yokukhipha, futhi ucezu lokuhlola ubude be-400mm luthathwa phakathi kwephrofayili eqediwe ekhishwe. Ububanzi besampula bungu-150mm nobude bungu-10.00mm.

Amasampula athathiwe ahlukaniswa futhi abe ngaphansi kokwelashwa okuyisixazululo futhi. Izinga lokushisa lesisombululo lalingu-530 ° C futhi isikhathi sesisombululo sasingu-4 amahora. Ngemva kokuwakhipha, amasampula afakwa ethangini elikhulu lamanzi elinobubanzi bamanzi obuyi-100mm. Ithangi lamanzi elikhudlwana lingaqinisekisa ukuthi izinga lokushisa lamanzi ethangini lamanzi lishintsha kancane ngemva kokuba isampula ekuzoni 1 selipholiswe ngamanzi, okuvimbela ukwanda kwezinga lokushisa lamanzi ukuthi lingaphazamisi amandla okupholisa amanzi. Ngesikhathi sokupholisa amanzi, qiniseka ukuthi izinga lokushisa lamanzi liphakathi kuka-20-25 ° C. Amasampula acishiwe ayemdala ku-165°C*8h.

Thatha ingxenye yesampula engu-400mm ubude obungu-30mm ububanzi obungu-10mm ubukhulu, bese wenza ukuhlolwa kokuqina kwe-Brinell. Yenza izilinganiso ezi-5 njalo ngo-10mm. Thatha inani elimaphakathi lokuqina kwe-Brinell okungu-5 njengomphumela wokuqina kwe-Brinell kuleli phuzu, bese ubheka iphethini yokushintsha ubulukhuni.

Izakhiwo zemishini zephrofayili zahlolwa, futhi ingxenye eqinile ehambisanayo engu-60mm yalawulwa ezindaweni ezihlukene zesampula engu-400mm ukuze kubhekwe izakhiwo eziqinile kanye nendawo yokuphuka.

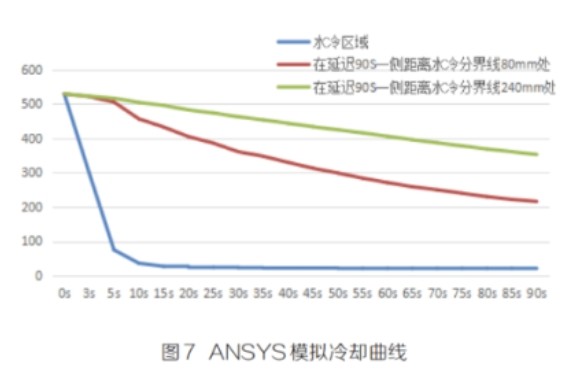

Inkambu yokushisa yokucisha okupholiswe ngamanzi kwesampula kanye nokucisha ngemva kokulibaziseka kwama-90s kwalingiswa ngesofthiwe ye-ANSYS, futhi izilinganiso zokupholisa zamaphrofayela ezindaweni ezihlukene zahlaziywa.

2. Imiphumela yokuhlola nokuhlaziya

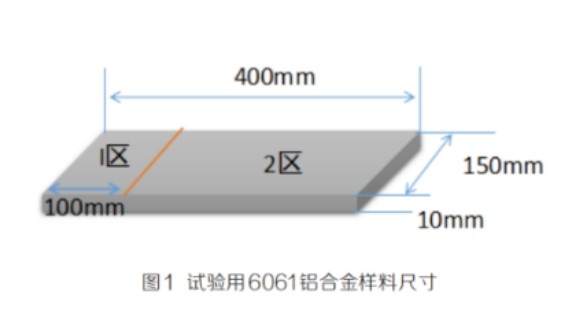

2.1 Imiphumela yokuhlolwa kokuqina

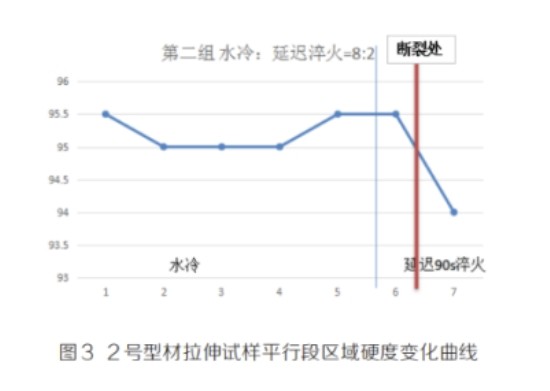

Umfanekiso wesi-2 ubonisa ijika lokushintsha kokuqina kwesampula elide elingu-400mm likalwa umhloli wokuqina we-Brinell (ubude beyunithi ye-abscissa bumele u-10mm, futhi isikali esingu-0 siwumugqa ohlukanisayo phakathi kokucisha okuvamile nokulibaziseka kokucisha). Kungatholakala ukuthi ukuqina ekugcineni okupholiswe ngamanzi kuzinzile cishe ku-95HB. Ngemuva komugqa ohlukanisayo phakathi kokucisha ukupholisa kwamanzi kanye nokubambezeleka kokupholisa amanzi ngama-90s, ubulukhuni buqala ukwehla, kodwa izinga lokwehla lihamba kancane ekuqaleni. Ngemva kuka-40mm (89HB), ukuqina kwehla kakhulu, futhi kwehla kunani eliphansi kakhulu (77HB) ngo-80mm. Ngemuva kwe-80mm, ubulukhuni abuzange buqhubeke nokuncipha, kodwa bukhuphuke ngezinga elithile. Ukwanda bekukuncane uma kuqhathaniswa. Ngemuva kwe-130mm, ubulukhuni bahlala bungashintshile cishe ku-83HB. Kungacatshangwa ukuthi ngenxa yomphumela wokushisa, izinga lokupholisa lengxenye ebambezelekile yokucisha lishintshile.

2.2 Imiphumela yokuhlolwa kokusebenza nokuhlaziya

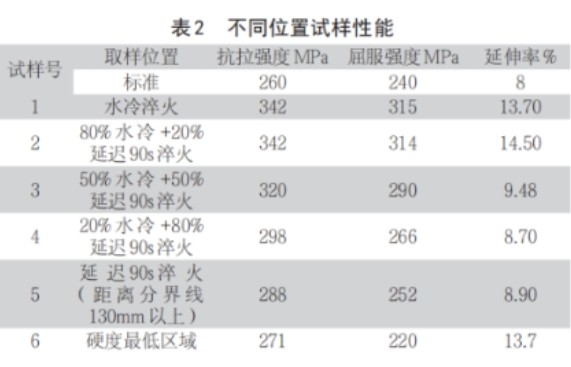

Ithebula lesi-2 libonisa imiphumela yokuhlolwa okuqinile okwenziwe kumasampuli athathwe ezindaweni ezihlukene zesigaba esifanayo. Kungatholakala ukuthi amandla okuqina namandla okukhiqiza we-No. 1 no-No. 2 cishe akukho shintsho. Njengoba ingxenye yokuphela kokucisha okubambezelekile ikhula, amandla okubamba namandla okuphuma kwe-alloy akhombisa ukwehla okuphawulekayo. Kodwa-ke, amandla aqinile endaweni ngayinye yesampula angaphezulu kwamandla ajwayelekile. Kuphela endaweni enobunzima obuphansi kakhulu, amandla okukhiqiza aphansi kunezinga lesampula, ukusebenza kwesampula akufanelekile.

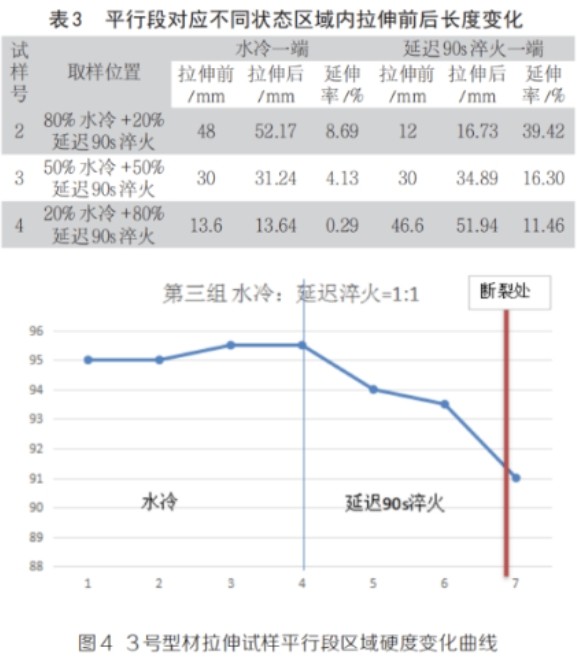

Umfanekiso wesi-4 ubonisa imiphumela yezakhiwo eziqinile zesampula No. 3. Ingatholakala kuMfanekiso 4 ukuthi ukude kakhulu nomugqa ohlukanisayo, kunciphisa ubulukhuni bokuphela kokucisha okubambezelekile. Ukuncipha kokuqina kubonisa ukuthi ukusebenza kwesampula kuncishisiwe, kodwa ukuqina kuncipha kancane, kuphela kuncipha ukusuka ku-95HB kuya cishe ku-91HB ekupheleni kwesigaba esihambisanayo. Njengoba kungabonakala emiphumeleni yokusebenza kuThebula 1, amandla okubamba ehla esuka ku-342MPa aya ku-320MPa ngokupholisa amanzi. Ngesikhathi esifanayo, kwatholakala ukuthi iphuzu lokuphuka lesampula eliqinile libuye libe sekupheleni kwesigaba esihambisanayo nobulukhuni obuphansi kakhulu. Lokhu kungenxa yokuthi ikude nokupholisa amanzi, ukusebenza kwe-alloy kuyancishiswa, futhi isiphetho sifinyelela umkhawulo wamandla okuqina kuqala ukuze wenze i-necking phansi. Okokugcina, hlukana nephuzu lokusebenza eliphansi kakhulu, futhi isikhundla sekhefu sihambisana nemiphumela yokuhlolwa kokusebenza.

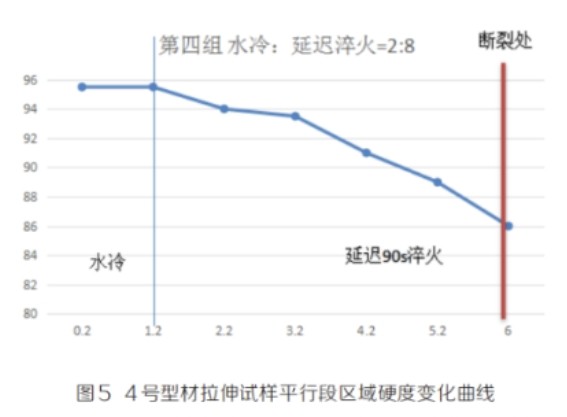

Umfanekiso wesi-5 ubonisa ijika elinzima lesigaba esihambisanayo sesampula No. 4 kanye nesimo sokuphuka. Kungatholakala ukuthi ukude kakhulu nomugqa wokuhlukanisa amanzi wokupholisa, kunciphisa ubulukhuni bokuphela kokucisha okubambezelekile. Ngesikhathi esifanayo, indawo yokuphuka nayo isekupheleni lapho ubulukhuni buphansi kakhulu, ukuphuka okungu-86HB. Kusukela kuThebula 2, kutholakala ukuthi cishe akukho deformation yepulasitiki ekugcineni okupholiswe ngamanzi. Kuthebula 1, kutholakala ukuthi ukusebenza kwesampula (amandla aqinile 298MPa, isivuno esingu-266MPa) kwehle kakhulu. Amandla aqinile angama-298MPa kuphela, angafinyeleli kumandla okukhiqiza okuphela kwamanzi okupholisa (315MPa). Isiphetho sakhe intamo phansi lapho ingaphansi kuka-315MPa. Ngaphambi kokuphuka, ukuguqulwa kwe-elastic kuphela kwenzeka endaweni epholile ngamanzi. Njengoba ukucindezeleka kwanyamalala, ukucindezeleka ekupheleni kwamanzi okupholile kwaphela. Ngenxa yalokho, inani le-deformation endaweni yokupholisa amanzi kuThebula 2 cishe alikho ushintsho. Isampula iphuka ekupheleni komlilo wezinga elibambezelekile, indawo ekhubazekile iyancishiswa, futhi ukuqina kokuphela kuphansi kakhulu, okuholela ekunciphiseni okukhulu kwemiphumela yokusebenza.

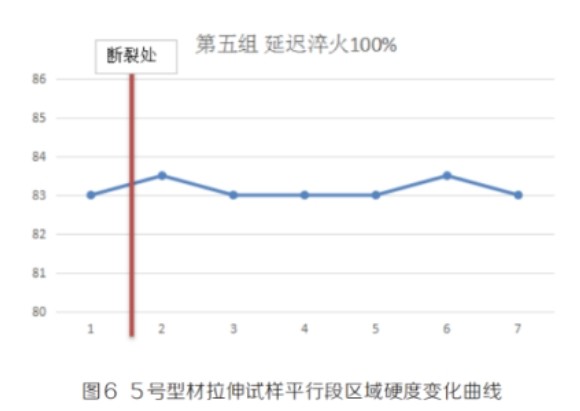

Thatha amasampula endaweni yokucisha ebambezeleke ngo-100% ekugcineni kwesifanekiso esingu-400mm. Umfanekiso 6 ukhombisa ijika lobulukhuni. Ukuqina kwesigaba esihambisanayo kuncipha cishe ku-83-84HB futhi kuzinzile. Ngenxa yenqubo efanayo, ukusebenza kucishe kufane. Alikho iphethini elisobala elitholakala endaweni yokuphuka. Ukusebenza kwe-alloy kungaphansi kwalokho kwesampula elicinywe ngamanzi.

Ukuze kuqhutshekwe nokuhlola ukujwayela kokusebenza nokuphuka, ingxenye ehambisanayo yesampula eqinile yakhethwa eduze nendawo ephansi yokuqina (77HB). Kusukela kuThebula 1, kutholakale ukuthi ukusebenza kuncishiswe kakhulu, futhi iphuzu lokuphuka livele endaweni ephansi kakhulu yobunzima kuMfanekiso 2.

2.3 Imiphumela yokuhlaziya ye-ANSYS

Umfanekiso wesi-7 ubonisa imiphumela yokulingisa kwe-ANSYS yamajika okupholisa ezindaweni ezihlukene. Kuyabonakala ukuthi izinga lokushisa lesampula endaweni yokupholisa amanzi lehla ngokushesha. Ngemuva kwama-5s, izinga lokushisa lehla laya ngaphansi kuka-100 ° C, futhi ku-80mm ukusuka emgqeni wokuhlukanisa, izinga lokushisa lehla laya cishe ku-210 ° C kuma-90s. Isilinganiso sokwehla kwezinga lokushisa ngu-3.5°C/s. Ngemva kwemizuzwana engu-90 endaweni yokupholisa umoya esigcinayo, izinga lokushisa liyehla lifinyelele cishe ku-360°C, ngesilinganiso sokwehla esimaphakathi esingu-1.9°C/s.

Ngokuhlaziywa kokusebenza kanye nemiphumela yokulingisa, kutholakala ukuthi ukusebenza kwendawo yokupholisa amanzi kanye nendawo yokucisha ebambezelekile kuyiphethini yoshintsho eqala ngokuncipha bese ikhuphuka kancane. Kuthintwa ukupholisa kwamanzi eduze komugqa ohlukanisayo, ukuqhutshwa kokushisa kubangela isampula endaweni ethile yehle ngenani lokupholisa elingaphansi kwalelo lokupholisa amanzi (3.5°C/s). Ngenxa yalokho, i-Mg2Si, eyaqina ku-matrix, yehla ngobuningi kule ndawo, futhi izinga lokushisa lehla laya cishe ku-210°C ngemva kwemizuzwana engu-90. Inani elikhulu le-Mg2Si elinemvula liholele kumthelela omncane wokupholisa amanzi ngemva kwamasekhondi angu-90. Inani lesigaba sokuqinisa i-Mg2Si elenyuka ngemva kokwelashwa kokuguga lehliswa kakhulu, futhi ukusebenza kwesampula kwabe sekuncipha. Kodwa-ke, indawo yokucisha ebambezelekile ekude kakhulu nolayini ohlukanisayo ayithinteki kangako ngokuqhutshwa kokushisa okupholisa amanzi, futhi ingxubevange ipholisa kancane ngaphansi kwezimo zokupholisa komoya (izinga lokupholisa elingu-1.9°C/s). Ingxenye encane kuphela yesigaba se-Mg2Si ekhuphuka kancane, futhi izinga lokushisa lingu-360C ngemva kwama-90s. Ngemuva kokupholisa amanzi, iningi lesigaba se-Mg2Si lisese-matrix, futhi liyahlakazeka futhi lihle ngemva kokuguga, okudlala indima yokuqinisa.

3. Isiphetho

Kutholwe ngokuhlolwa ukuthi ukucisha ukubambezeleka kuzodala ubulukhuni bendawo yokucisha ebambezelekile empambanweni yokucisha okujwayelekile kanye nokucisha okulibazisekayo kuqale kwehle bese kwanda kancane kuze kube yilapho kusimamisa.

Ku-6061 aluminium alloy, amandla okuqina ngemva kokucisha okuvamile nokubambezeleka kokucisha amasekhondi angu-90 angu-342MPa no-288MPa ngokulandelana, futhi amandla esivuno angu-315MPa no-252MPa, womabili ahlangabezana nezindinganiso zokusebenza zesampula.

Kukhona isifunda esinobunzima obuphansi kakhulu, obuncishisiwe busuka ku-95HB ukuya ku-77HB ngemva kokucisha okuvamile. Ukusebenza lapha nakho kuphansi kakhulu, kunamandla aqinile we-271MPa namandla okukhiqiza angama-220MPa.

Ngokuhlaziywa kwe-ANSYS, kutholwe ukuthi izinga lokupholisa endaweni yokusebenza ephansi kakhulu ngeminyaka yawo-90s lehle ngo-3.5°C ngesekhondi, okubangele isixazululo esiqinile esinganele sesigaba sokuqinisa se-Mg2Si. Ngokwalesi sihloko, kungase kubonakale ukuthi indawo eyingozi yokusebenza ibonakala endaweni yokucisha ebambezelekile lapho kuhlangana khona ukucisha okujwayelekile kanye nokulibaziseka kokucisha, futhi alikude nendawo ehlanganayo, enokubaluleka okubalulekile okuyisiqondiso ekugcinweni okunengqondo kodoti wenqubo yokuphela komsila we-extrusion.

Ihlelwe nguMay Jiang evela kwaMAT Aluminium

Isikhathi sokuthumela: Aug-28-2024