1.Isingeniso

Ama-alloys e-aluminium anamandla aphakathi nendawo abonisa izici zokucubungula ezivumayo, ukuzwela kokucisha, ukuqina komthelela, nokumelana nokugqwala. Baqashwe kakhulu ezimbonini ezahlukahlukene, njengezogesi nezasolwandle, ukwenza amapayipi, izinduku, amaphrofayili, nezintambo. Njengamanje, kunesidingo esikhulayo samabha we-aluminium alloy angama-6082. Ukuze kuhlangatshezwane nezidingo zemakethe kanye nezidingo zomsebenzisi, senze izivivinyo kuzinqubo ezihlukene zokushisisa i-extrusion kanye nezinqubo zokugcina zokwelashwa kokushisa kwamabha angu-6082-T6. Umgomo wethu bekuwukubona uhlobo lokwelapha ukushisa elenelisa izimfuneko zokusebenza kwemishini zala mabha.

2.Izinto Zokuhlola kanye Nokugeleza Kwenqubo Yokukhiqiza

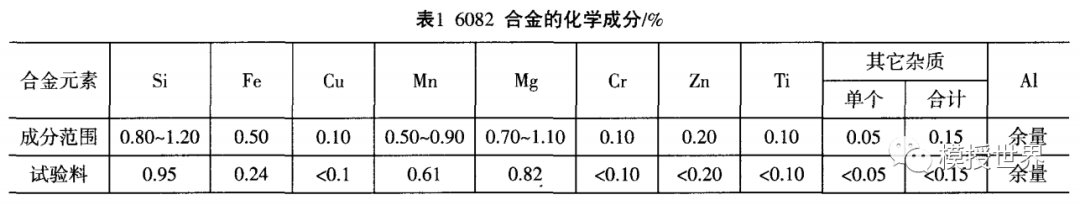

2.1 Izinto Zokuhlola

Ama-ingots osayizi we-Ф162 × 500 akhiqizwa kusetshenziswa indlela yokuphonsa eqhubekayo futhi angaphansi kokwelashwa okungewona umfaniswano. Ikhwalithi ye-metallurgical ye-ingots ihambisana nezindinganiso zobuchwepheshe zokulawula kwangaphakathi kwenkampani. Ukwakheka kwamakhemikhali engxubevange ye-6082 kuboniswa kuThebula 1.

2.2 Ukugeleza Kwenqubo Yokukhiqiza

Imigoqo yokuhlola engu-6082 yayinokucaciswa kwe-Ф14mm. Isiqukathi se-extrusion sasinobubanzi obungu-Ф170mm nomklamo we-extrusion wezimbobo ezi-4 kanye ne-extrusion coefficient engu-18.5. Ukugeleza kwenqubo ethile kwakuhlanganisa ukushisa ingot, i-extrusion, ukucisha, ukwelula ukuqondisa kanye nesampula, ukuqondisa kwe-roller, ukusika kokugcina, ukuguga okwenziwayo, ukuhlolwa kwekhwalithi, nokulethwa.

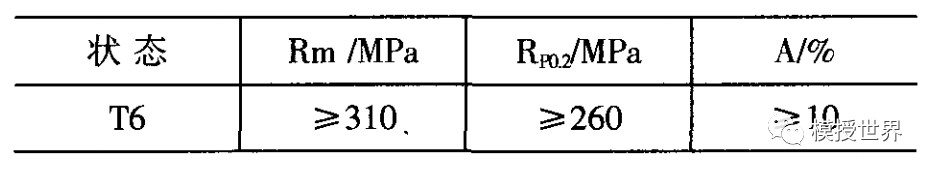

3.Izinjongo Zokuhlola

Inhloso yalolu cwaningo bekuwukukhomba amapharamitha wenqubo yokwelashwa kokushisa kwe-extrusion kanye nemingcele yokugcina yokwelapha ukushisa okuthonya ukusebenza kwamabha angu-6082-T6, ekugcineni kufinyelele izidingo zokusebenza ezijwayelekile. Ngokwamazinga, izakhiwo zemishini ye-longitudinal ye-alloy engu-6082 kufanele zihlangabezane nezicaciso ezisohlwini lweThebula lesi-2.

4.Indlela Yokuhlola

4.1 Uphenyo Lokushiswa Kokushisa Kwe-Extrusion

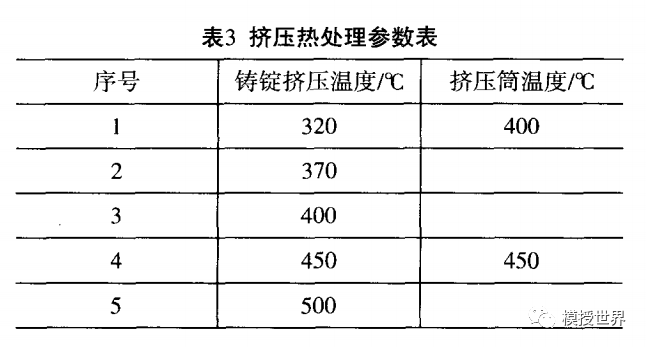

Uphenyo lokwelashwa kokushisa kwe-extrusion lugxile kakhulu emiphumeleni yokukhipha izinga lokushisa le-ingot extrusion kanye nezinga lokushisa lesitsha se-extrusion kuzakhiwo zokukhanda. Ukukhethwa kwepharamitha ethile kuchazwe kuThebula 3.

4.2 Isixazululo Esiqinile kanye Nophenyo Lokuguga Kokwelashwa Kokushisa

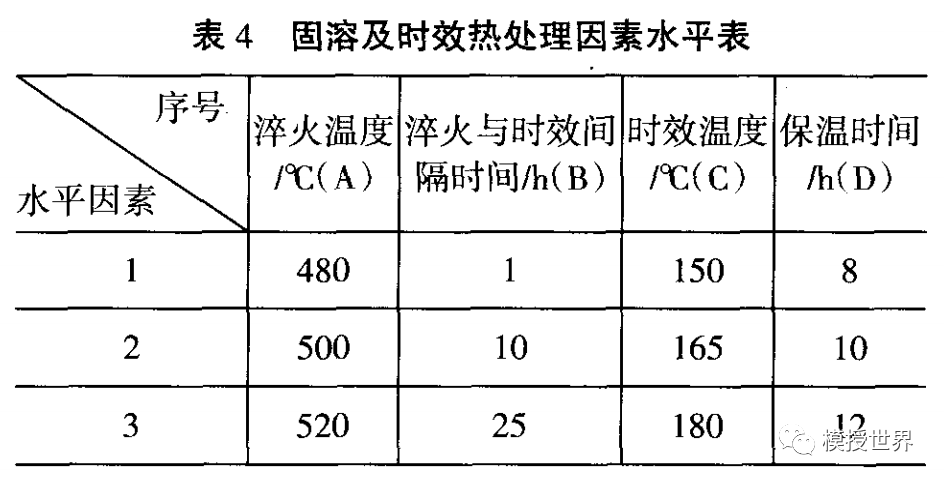

Idizayini yokuhlola ye-orthogonal yasetshenziswa ngesisombululo esiqinile kanye nenqubo yokwelapha ukushisa okuguga. Amazinga wesici akhethiwe anikezwe kuThebula 4, nethebula lokuklama le-orthogonal elichazwe ngokuthi IJ9(34).

5.Imiphumela kanye nokuhlaziya

5.1 Imiphumela Yokuhlola Ukwelashwa Kokushisa Okungeziwe kanye Nokuhlaziya

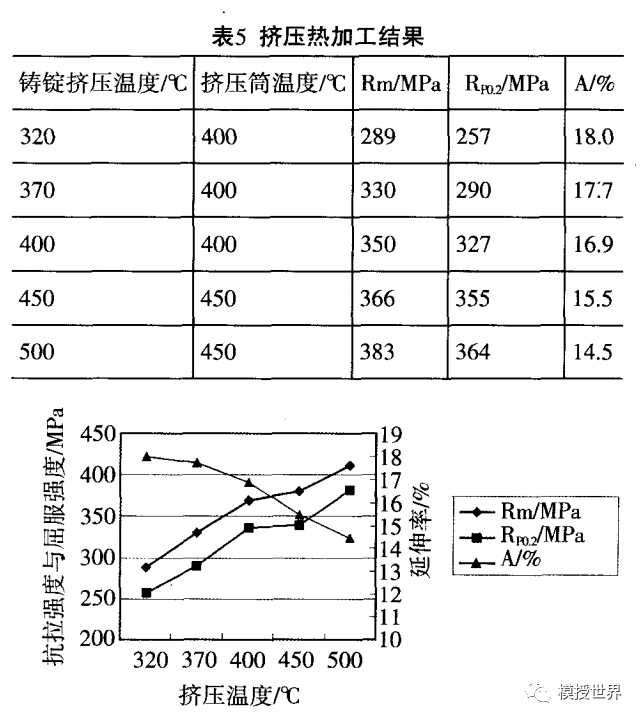

Imiphumela yokuhlolwa kokwelashwa kokushisa kwe-extrusion yethulwa kuThebula lesi-5 kanye noMdwebo 1. Amasampula ayisishiyagalolunye athathwe eqenjini ngalinye, futhi izilinganiso zabo zokusebenza kwemishini zanqunywa. Ngokusekelwe ekuhlaziyweni kwe-metallographic kanye nokwakhiwa kwamakhemikhali, i-regimen yokwelapha ukushisa yasungulwa: ukucisha ku-520 ° C imizuzu engu-40 nokuguga ku-165 ° C amahora angu-12. Kusukela kuThebula 5 kanye noMdwebo 1, kungaqashelwa ukuthi njengoba izinga lokushisa le-ingot extrusion kanye nezinga lokushisa lesitsha se-extrusion likhuphuka, kokubili amandla aqinile namandla okukhiqiza akhuphuka kancane kancane. Imiphumela emihle kakhulu itholwe emazingeni okushisa e-extrusion angu-450-500°C kanye nezinga lokushisa lesitsha se-extrusion elingu-450°C, elihlangabezana nezidingo ezijwayelekile. Lokhu kwakungenxa yomphumela wokuqina komsebenzi obandayo emazingeni okushisa aphansi e-extrusion, okubangela ukuhlukana komngcele wokusanhlamvu nokwanda kokubola kwesisombululo esiqinile phakathi kwe-A1 ne-Mn ngesikhathi sokushisa ngaphambi kokucisha, okuholela ekukhanyeni kabusha. Njengoba izinga lokushisa le-extrusion likhuphuka, amandla okugcina e-Rm omkhiqizo athuthuke kakhulu. Lapho izinga lokushisa lesitsha se-extrusion lisondela noma lidlula izinga lokushisa le-ingot, ukuwohloka okungalingani kwehla, kunciphisa ukujula kwamasongo okusanhlamvu okumahhadla futhi kwandise amandla esivuno sika-Rm. Ngakho, imingcele enengqondo yokwelashwa kokushisa kwe-extrusion yilezi: izinga lokushisa le-ingot extrusion elingu-450-500°C kanye nezinga lokushisa lesitsha se-extrusion elingu-430-450°C.

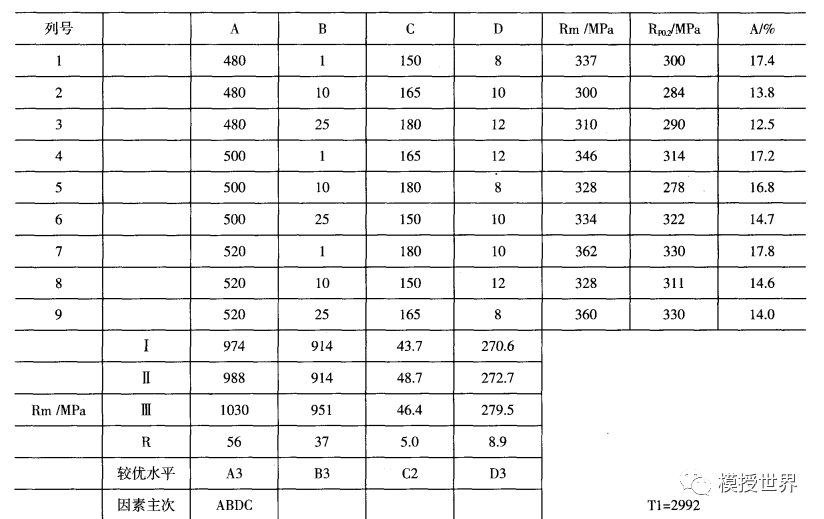

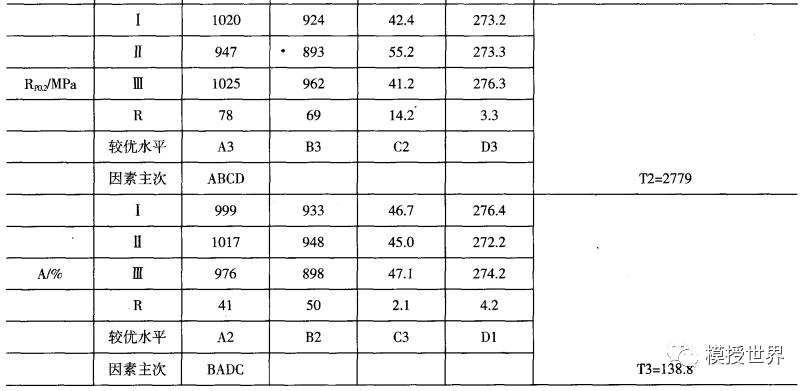

5.2 Isixazululo Esiqinile Nokuguga Kwemiphumela Yokuhlola Ye-Orthogonal Nokuhlaziya

Ithebula lesi-6 lembula ukuthi amazinga afaneleke yi-A3B1C2D3, ecisha ku-520°C, izinga lokushisa lokuguga lokuzenzela eliphakathi kuka-165-170°C, kanye nobude bokuguga bamahora angu-12, okuholela ekubeni namandla aphezulu kanye nepulasitiki yezinsimbi. Inqubo yokucisha yakha isisombululo esiqinile esine-supersaturated. Emazingeni okushisa aphansi okucisha, ukuhlangana kwesisombululo esiqinile esine-supersaturated kuncipha, kuthinte amandla. Izinga lokushisa elicishayo elicishe libe ngu-520°C liwuthuthukisa kakhulu umphumela wokuqinisa isisombululo esiqinile esibangelwa ukucisha. Isikhawu phakathi kokucisha nokuguga okwenziwa, okungukuthi, ukugcinwa kwezinga lokushisa kwegumbi, kuthonya kakhulu izakhiwo zemishini. Lokhu kushiwo ikakhulukazi izinduku ezinganwetshiwe ngemva kokucisha. Lapho isikhawu phakathi kokucisha nokuguga sidlula ihora elingu-1, amandla, ikakhulukazi amandla okukhiqiza, ancipha kakhulu.

5.3 Ukuhlaziywa kwe-Metallographic Microstructure

Ukuhlaziya okuphakeme kakhulu nokuhlaziya kwenziwa kumabha angu-6082-T6 emazingeni okushisa esisombululo esiqinile angu-520°C no-530°C. Izithombe ezikhuliswe kakhulu zembule imvula eyingxube efanayo enezinhlayiya zesigaba semvula ezisatshalaliswe ngokulinganayo. Ukuhlaziywa kokukhanya kwe-polarized kusetshenziswa okokusebenza kwe-Axiovert200 kubonise umehluko ohlukile ezithombeni zesakhiwo sokusanhlamvu. Indawo emaphakathi ibonise okusanhlamvu okuncane nokufana, kuyilapho imiphetho ikhombisa ukuhlanganiswa kabusha okusanhlamvu okude. Lokhu kungenxa yokukhula kwe-crystal nuclei emazingeni okushisa aphezulu, okwenza amahholo afane nenaliti.

6.Ukuhlolwa Komkhuba Wokukhiqiza

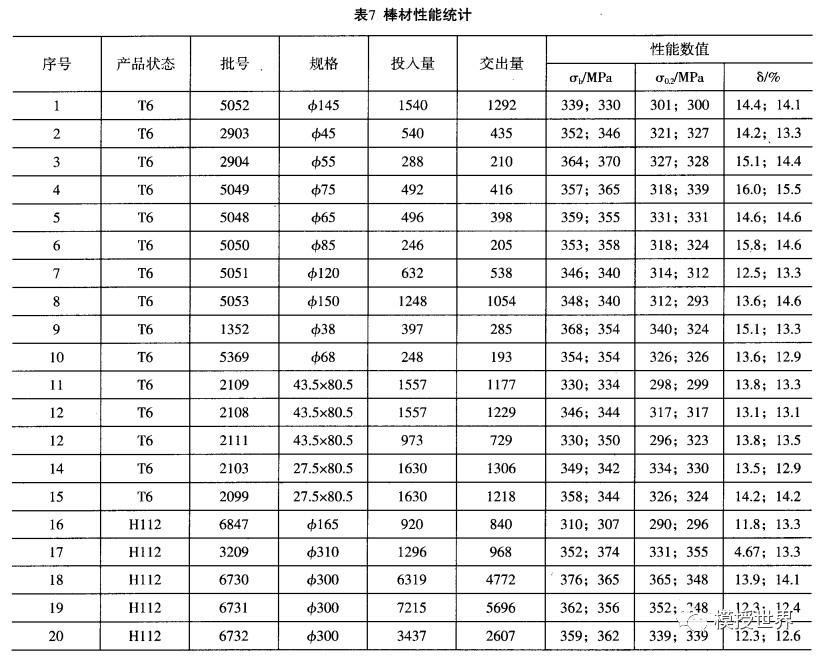

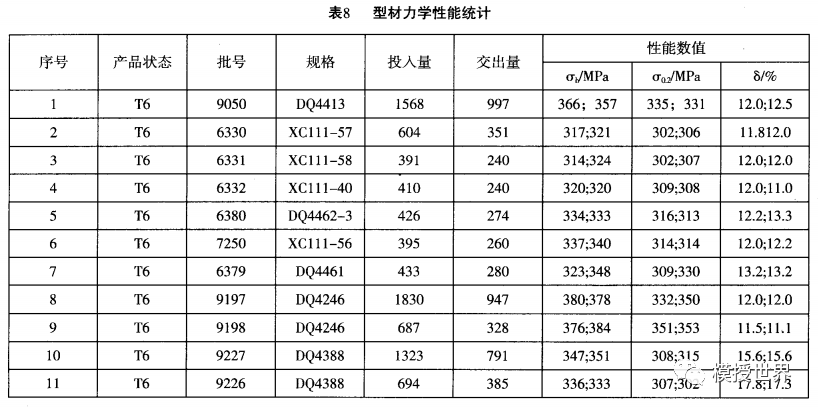

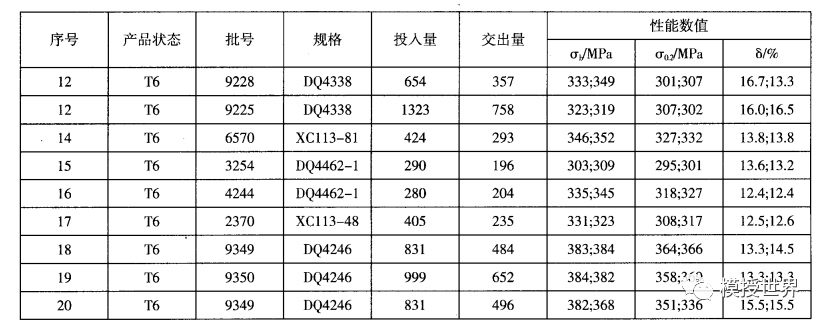

Ekukhiqizweni kwangempela, izibalo zokusebenza kwemishini zenziwa kumaqoqwana angama-20 wamabha kanye namaqoqo angama-20 wamaphrofayili. Imiphumela iboniswa kuThebula 7 no-8. Ekukhiqizeni kwangempela, inqubo yethu yokukhipha yenziwa emazingeni okushisa aphumela kumasampula esimo se-T6, futhi ukusebenza komshini kuhlangabezane namanani ahlosiwe.

7.Isiphetho

(1) Imingcele yokwelashwa kokushisa kwe-Extrusion: I-ingots extrusion lokushisa kwe-450-500 ° C; Izinga lokushisa lesitsha se-extrusion elingu-430-450°C.

(2) Imingcele yokugcina yokwelapha ukushisa: Izinga lokushisa elilungile lesisombululo esiqinile lika-520-530 ° C; izinga lokushisa lokuguga ku-165 ± 5 ° C, ubude bokuguga amahora angu-12; isikhawu phakathi kokucisha nokuguga akufanele sidlule ihora elingu-1.

(3) Ngokusekelwe ekuhloleni okusebenzayo, inqubo yokwelapha ukushisa okusebenzayo ihlanganisa: izinga lokushisa le-extrusion lika-450-530 ° C, izinga lokushisa lesitsha se-extrusion lika-400-450 ° C; izinga lokushisa eliqinile lesisombululo se-510-520 ° C; uhlelo lokuguga lwe-155-170 ° C amahora angu-12; akukho mkhawulo othize esikhawulweni phakathi kokucisha nokuguga. Lokhu kungafakwa eziqondisweni zokusebenza zenqubo.

Ihlelwe nguMay Jiang evela kwaMAT Aluminium

Isikhathi sokuthumela: Mar-15-2024