Uma izici zomshini ze-extrusions zingekho njengoba kulindelekile, ukunaka kuvame ukugxila ekwakhiweni kokuqala kwe-billet noma izimo ze-extrusion/ukuguga. Bambalwa abantu ababuza ukuthi i-homogenization ngokwayo ingaba yinkinga. Eqinisweni, isigaba se-homogenization sibalulekile ekukhiqizeni ama-extrusions aphezulu. Ukwehluleka ukulawula kahle isinyathelo se-homogenization kungaholela ku:

● Ukwenyuka kwengcindezi yokuphumelela

●Ukukhubazeka okwengeziwe

●Ukwakheka kwe-streak ngemva kwe-anodizing

●Ijubane eliphansi le-extrusion

●Izakhiwo ezingezinhle

Isiteji se-homogenization sinezinjongo ezimbili eziyinhloko: ukucwenga izinhlanganisela ze-iron-containing intermetallic, kanye nokusabalalisa kabusha i-magnesium (Mg) ne-silicon (Si). Ngokuhlola i-microstructure ye-billet ngaphambi nangemva kwe-homogenization, umuntu angabikezela ukuthi i-billet izokwenza kahle yini ngesikhathi sokukhishwa.

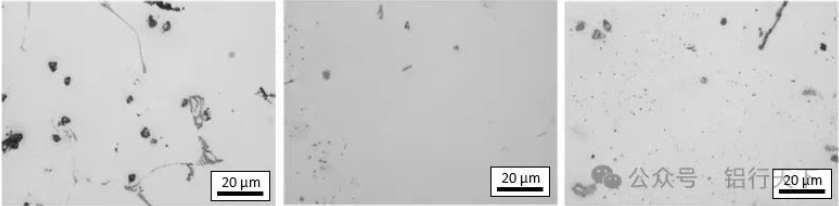

Umthelela we-Billet Homogenization ekuqineni

Kuma-extrusions angu-6XXX, amandla avela ezigabeni ze-Mg- ne-Si-rich ezakhiwe ngesikhathi sokuguga. Ikhono lokwenza lezi zigaba lincike ekubekeni izakhi zibe isisombululo esiqinile ngaphambi kokuguga. Ukuze i-Mg ne-Si ekugcineni ibe yingxenye yesisombululo esiqinile, insimbi kufanele icime ngokushesha ukusuka ngaphezu kuka-530 °C. Emazingeni okushisa angaphezu kwaleli phuzu, i-Mg ne-Si zincibilika zibe i-aluminium. Kodwa-ke, ngesikhathi se-extrusion, insimbi ihlala ngaphezu kwalokhu kushisa isikhathi esifushane. Ukuqinisekisa ukuthi zonke i-Mg ne-Si ziyancibilika, izinhlayiya ze-Mg ne-Si kudingeka zibe zincane uma kuqhathaniswa. Ngeshwa, ngesikhathi sokusakaza, i-Mg ne-Si idlula njengamabhulokhi e-Mg₂Si amakhulu kakhulu (Fig. 1a).

Umjikelezo we-homogenization ojwayelekile wamabhilidi angama-6060 ngu-560 °C amahora ama-2. Phakathi nale nqubo, njengoba i-billet ihlala ngaphezu kwe-530 ° C isikhathi eside, i-Mg₂Si iyancibilika. Lapho ipholisa, iphinde yehla ngokusabalalisa okuhle kakhulu (Fig. 1c). Uma izinga lokushisa le-homogenization lingaphakeme ngokwanele, noma isikhathi sifushane kakhulu, ezinye izinhlayiya ezinkulu ze-Mg₂Si zizohlala. Uma lokhu kwenzeka, ikhambi eliqinile ngemva kokukhishwa liqukethe i-Mg ne-Si encane, okwenza kungenzeki ukwakha ukuminyana okuphezulu kwezimvula eziqinile—okuholela ekwehleni kwezakhiwo zemishini.

Umdwebo 1. Ama-micrographs abonakalayo wamabhilidi angu-6060 aphucuziwe kanye nangu-2% we-HF-etched: (a) as-cast, (b) afakwe i-homogenized kancane, (c) enziwe abe homogenized ngokugcwele.

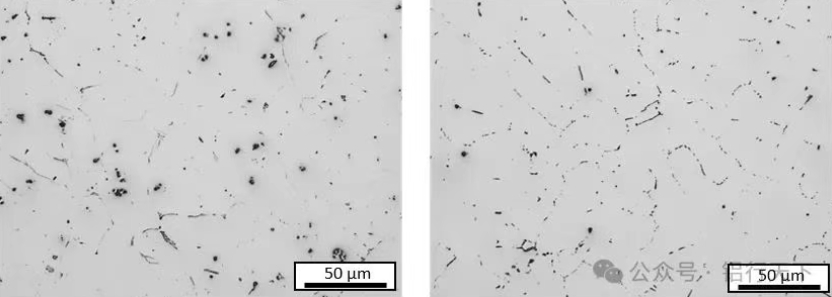

Iqhaza le-Homogenization kuma-Iron-containing Intermetallics

I-ayoni (Fe) inomthelela omkhulu ekuqineni kokuphuka kunamandla. Kumaalloyi angu-6XXX, izigaba ze-Fe zivame ukwakha u-β-phase (Al₅(FeMn)Si noma u-Al₈.₉(FeMn)₂Si₂) phakathi nokusakaza. Lezi zigaba zinkulu, ziyi-angular, futhi ziphazamisa i-extrusion (eqokonyiswe ku-Fig. 2a). Ngesikhathi se-homogenization, izakhi ezinzima (Fe, Mn, njll) zihlakazeka, futhi izigaba ezinkulu ze-angular ziba zincane futhi ziyindilinga (Fig. 2b).

Kusukela ezithombeni ze-optical zodwa, kunzima ukuhlukanisa izigaba ezihlukahlukene, futhi akunakwenzeka ukuzilinganisa ngokuthembekile. Kwa-Innoval, silinganisa i-billet homogenization sisebenzisa indlela yethu yokutholwa kwesici sangaphakathi kanye nokuhlukaniswa (i-FDC), ehlinzeka ngenani elingu-%α lamabhilidi. Lokhu kusenza sikwazi ukuhlola ikhwalithi ye-homogenization.

Umdwebo 2. Ama-micrographs optical of billets (a) ngaphambi kanye (b) ngemva kwe-homogenization.

Indlela Yokutholwa Nokuhlelwa Kwesici (i-FDC).

Umdwebo 3a ubonisa isampula epholishiwe ehlaziywe ngokuskena i-electron microscopy (SEM). I-thresholding thresholding technique ibe isisetshenziswa ukuze kuhlukaniswe futhi kukhonjwe i-intermetallic, ebonakala imhlophe kuFig. 3b. Le nqubo ivumela ukuhlaziywa kwezindawo ezifika ku-1 mm², okusho ukuthi izici ezingazodwana ezingaphezu kuka-1000 zingahlaziywa ngesikhathi esisodwa.

Umfanekiso 3. (a) Isithombe se-electron ehlakazekile se-homogenized 6060 billet, (b) ehlonzwe izici ezingazodwana kusukela ku-(a).

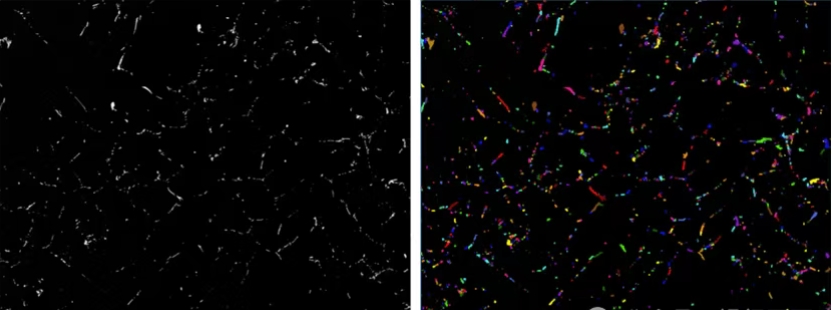

Ukubunjwa Kwezinhlayiya

Isistimu ye-Innoval ifakwe umtshina we-Oxford Instruments Xplore 30 energy-dispersive X-ray (EDX). Lokhu kuvumela ukuqoqwa okuzenzakalelayo okuzenzakalelayo kwe-EDX spectra kusuka endaweni ngayinye ekhonjiwe. Kusukela kule spectra, ukwakheka kwezinhlayiyana kunganqunywa, futhi isilinganiso se-Fe:Si esilinganiselwe.

Ngokuya ngokuqukethwe kwe-Mn noma i-Cr ye-alloy, ezinye izinto ezisindayo zingase zifakwe. Kwamanye ama-alloys angu-6XXX (ngezinye izikhathi ane-Mn ebalulekile), isilinganiso (Fe+Mn):Si sisetshenziswa njengereferensi. Lezi zilinganiso zingase ziqhathaniswe nalezo ezaziwayo eziqukethe i-Fe-containing intermetallics.

I-β-phase (Al₅(FeMn)Si noma i-Al₈.₉(FeMn)₂Si₂): (Fe+Mn):Si isilinganiso ≈ 2. α-phase (Al₁₂(FeMn)₃Si noma i-Al₈.₃(FeMn)₂, ukwakheka kuye ngokuthi. ₂Si): Isofthiwe yethu yangokwezifiso isivumela ukuthi simise umkhawulo futhi sihlukanise uhlamvu ngalunye njengo-α noma u-β, bese senza mephu izindawo zabo ngaphakathi kwesakhiwo esincane (Fig. 4). Lokhu kunikeza cishe iphesenti lika-α eliguquliwe ku-billet eyenziwe nge-homogenized.

Umdwebo 4. (a) Imephu ebonisa izinhlayiya ezihlukaniswe ngu-α- kanye no-β, (b) isakhiwo sokuhlakazeka sika-(Fe+Mn):izilinganiso ze-Si.

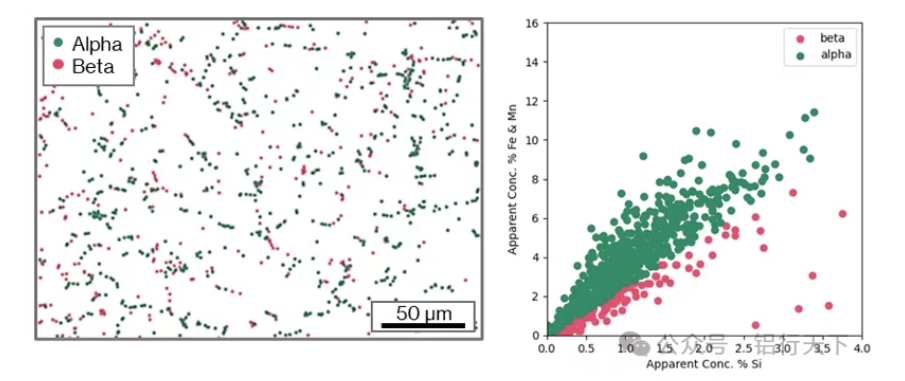

Lokho Idatha Engasitshela Ngayo

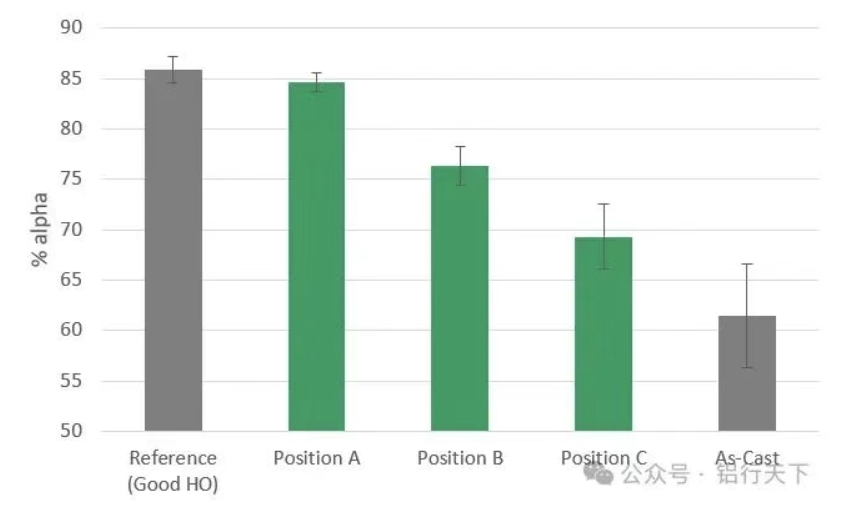

Umfanekiso wesi-5 ubonisa isibonelo sokuthi lolu lwazi lusetshenziswa kanjani. Kulesi simo, imiphumela ikhombisa ukushisa okungeyona into efanayo ngaphakathi kwesithando somlilo esithile, noma kungenzeka ukuthi izinga lokushisa le-setpoint alifinyelelwanga. Ukuhlola kahle izimo ezinjalo, kokubili i-billet yokuhlola kanye nereferensi yekhwalithi eyaziwayo kuyadingeka. Ngaphandle kwalokhu, ububanzi obulindelwe %α balokho kwakheka kwengxubevange abukwazi ukusungulwa.

Umfanekiso 5. Ukuqhathaniswa kwe-%α ezigabeni ezihlukene zesithando somlilo esisebenza kabi.

Isikhathi sokuthumela: Aug-30-2025