Nakuba cishe wonke ama-alloys e-aluminium ekwazi ukunwebeka ngokombono, ukuhlola ukunwebeka kwengxenye ethile kudinga ukucatshangelwa okuphelele kwezici ezinjengobukhulu, ijometri, uhlobo lwengxubevange, izidingo zokubekezelelana, isilinganiso se-scrap, isilinganiso se-extrusion, nesilinganiso solimi. Ukwengeza, kubalulekile ukunquma ukuthi i-extrusion eqondile noma engaqondile iyona ndlela yokwakha efaneleke kakhudlwana.

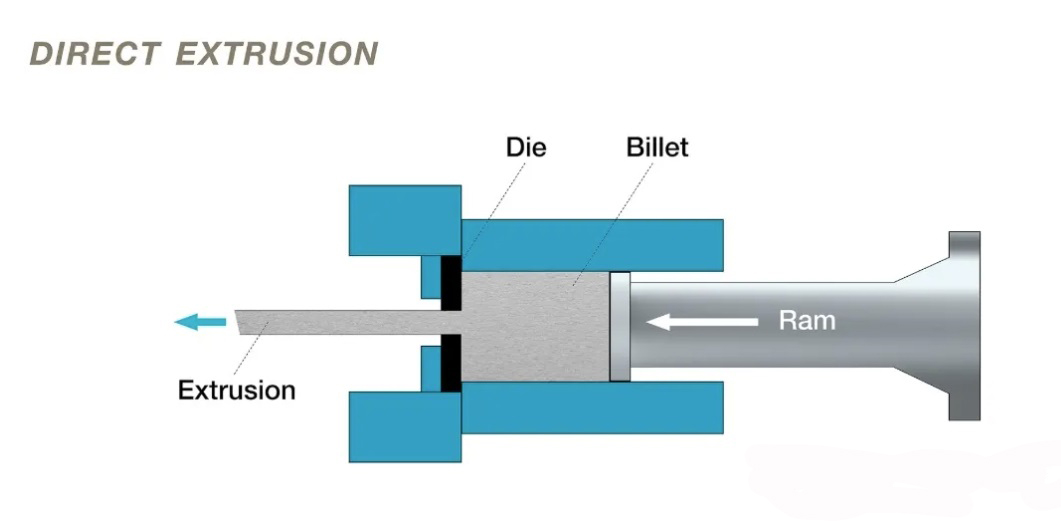

I-Extrusion eqondile iyinqubo evame ukusetshenziswa kakhulu, ebonakala ngokuklama kwayo okulula nokuvumelana nezimo okuqinile, okuyenza ifanelekele ukukhiqizwa okubanzi kwephrofayili. Ngale ndlela, i-aluminium billet eshisiwe ngaphambili iphushwa inqama ngefa elimile, futhi impahla igeleza ngendlela efanayo nenqama. Ukungqubuzana phakathi kwe-billet nesiqukathi kungokwemvelo kule nqubo. Lokhu kungqubuzana kubangela ukunqwabelana kokushisa kanye nokwenyuka kokusetshenziswa kwamandla, okuholela ekuhlukeni kwezinga lokushisa kanye nomsebenzi wokuguqula ngobude be-extrusion. Ngakho-ke, lokhu kuhlukahluka kungathinta ukwakheka kokusanhlamvu, i-microstructure, nokuzinza kwe-dimensional yomkhiqizo wokugcina. Ngaphezu kwalokho, njengoba ingcindezi ivame ukwehla kuwo wonke umjikelezo we-extrusion, ubukhulu bephrofayela bungase bungahambisani.

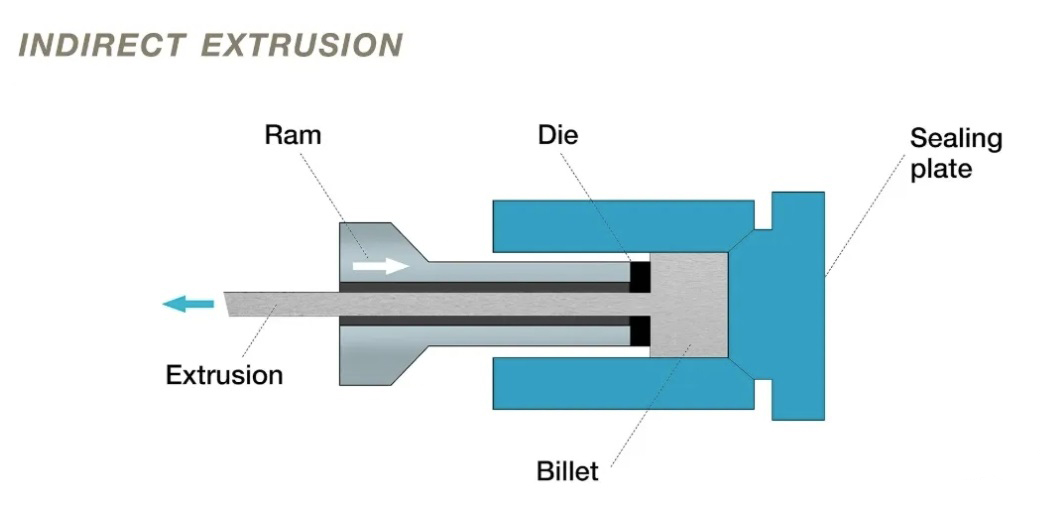

Ngokuphambene, i-extrusion engaqondile ifaka i-die ekhwezwe kunqama ye-extrusion efaka ingcindezi kwelinye icala le-billet ye-aluminium emile, ebangela ukuthi okokusebenza kugeleze kuhlene. Ngenxa yokuthi i-billet ihlala imile ihlobene nesiqukathi, akukho ukungqubuzana kwe-billet-to-container. Lokhu kubangela amandla okwakha angaguquki kanye nokufaka amandla kuyo yonke inqubo. Ukuwohloka okufanayo nezimo ezishisayo okuzuzwe ngemikhiqizo ekhiqiziwe ye-extrusion enokunemba okuthuthukisiwe kwe-dimensional, i-microstructure engaguquki kakhudlwana, kanye nezakhiwo zemishini ezithuthukisiwe. Le ndlela inenzuzo ikakhulukazi ezinhlelweni ezidinga ukungaguquguquki okuphezulu nokusebenziseka kalula, njengesitokwe somshini wesikulufa.

Naphezu kwezinzuzo zayo ze-metallurgical, i-extrusion engaqondile inemikhawulo ethile. Noma yikuphi ukungcoliswa okungaphezulu ku-billet kungathinta ngokuqondile isiphetho esingaphezulu se-extrudate, kwenze kube kudingekile ukususa indawo esakazwayo futhi kugcinwe indawo ehlanzekile ye-billet. Ukwengeza, ngenxa yokuthi ukufa kufanele kusekelwe futhi kuvumele i-extrudate ukuthi idlule, ububanzi obuvunyelwe bephrofayela buncishisiwe, kukhawulelwe usayizi womumo okhishwayo.

Ngenxa yezimo zayo zenqubo ezinzile, ukwakheka okufanayo, nokuvumelana kobukhulu obuphakeme, i-extrusion engaqondile isiphenduke indlela ebalulekile yokukhiqiza izinti ze-aluminium ezisebenza kahle kanye nemigoqo. Ngokunciphisa ukuhlukahluka kwenqubo ngesikhathi sokukhishwa, kuthuthukisa kakhulu ukusebenza nokuthembeka kwesicelo semikhiqizo eqediwe.

Isikhathi sokuthumela: Jul-16-2025