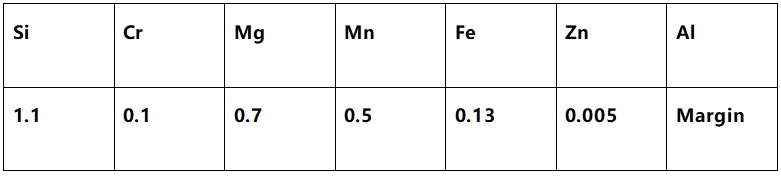

1. Ukwakheka kwengxubevange

2. Inqubo ye-Homogenization

390℃ x ukwahlukanisa okungu-1.0h + 575℃ x ukwahlukanisa okungu-8h, ukupholisa umoya onamandla ukuya ku-200℃ bese kuba ukupholisa amanzi.

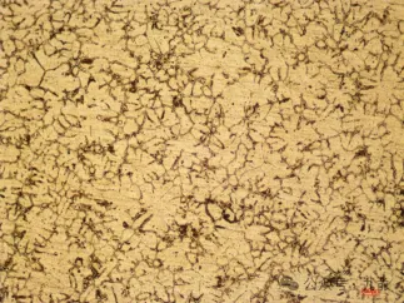

3. Isakhiwo se-Metallographic

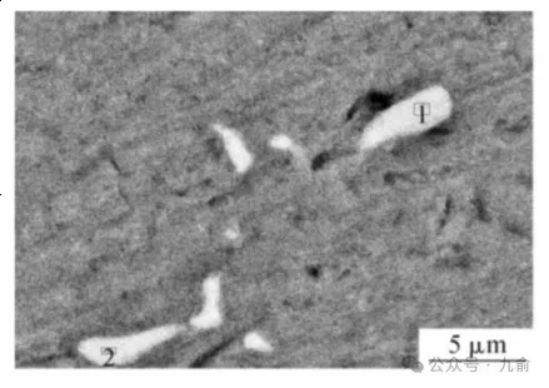

Umfanekiso 1 Isakhiwo se-Metallographic somgogodla we-6082 alloy ingot, ebhalwe yi-Keller reagent, enama-dendrites athuthuke kahle.

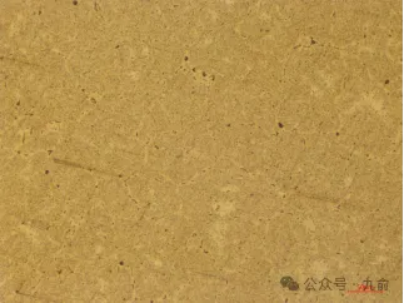

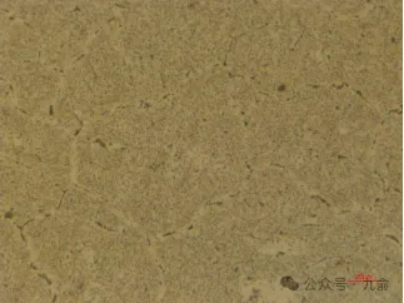

Umfanekiso 2 Isakhiwo se-Metallographic somgogodla we-6082 ingot ye-alloy, eqoshwe i-reagent ye-Keller, kanye nesakhiwo ngemva kwesisombululo esiqinile.

4. Umphumela wokwelashwa kokushisa kwe-homogenization kusakhiwo se-alloy

4.1 Njengoba kuboniswe ku-Figure 1, i-alloy inama-dendrites athuthuke kahle endaweni yokukhonkolo, futhi kunenani elikhulu lezigaba zemvula ezingalingani zenethiwekhi emingceleni yokusanhlamvu.

I-4.2 Njengoba amaphuzu ancibilikayo ezakhi ezihlukene ahlukile lapho i-alloy iqina, lesi senzo sokuqina esilandelanayo siholela ekwakhiweni okungalingani kwe-solute ngaphakathi kwekristalu, okubonakaliswa ngokuqondile ekukhiqizeni inombolo enkulu yezigaba zezulu zenethiwekhi emingceleni yokusanhlamvu.

4.3 Ku-microstructure ngemva kokwelashwa kwe-homogenization (Umfanekiso 2), inani lezigaba ezincishisiwe emingceleni yokusanhlamvu lincishiswa kakhulu, futhi usayizi wokusanhlamvu ukhula ngokuvumelana. Lokhu kungenxa yokuthi ukusakazeka kwama-athomu kuyathuthukiswa ngaphansi kwezinga lokushisa eliphezulu, ukuqedwa kokuhlukaniswa kanye nokuqedwa kwesigaba esingalingani kwenzeka ku-ingot, futhi izinhlanganisela zenethiwekhi emingceleni yokusanhlamvu zincibilika kancane.

4.4 Ngokuhlaziywa kwe-SEM, njengoba kuboniswe ku-FIG3, izingxenye ezihlukene zesigaba esinemvula zikhethelwe ukuhlaziywa kwe-EDS, okuqinisekisa ukuthi isigaba esinemvula kwakuyisigaba se-Al(MnFe)Si.

4.5 Ngesikhathi sokusakazwa kwe-alloy, inani elikhulu lesigaba semvula esine-Mn liyakhiwa, futhi ingxenye yalo igcinwa kusixazululo esiqinile esine-supersaturated. Ngemuva kokwelashwa kwe-homogenization yokushisa okuphezulu kanye nesikhathi eside, i-Mn supersaturated ku-matrix idlula ngendlela ye-Mn-containing compounds, ebonakala njengenani elikhulu lezinhlayiya ezihlakazekile zokubola kwe-Mn eziqukethe i-crystal (Figure 2).

4.6 Njengoba isigaba semvula siqukethe i-Mn element, sinokuzinza okuhle kwe-thermal. Ngokuqiniswa kokusabalalisa kwe-athomu, izinhlayiya zesigaba se-Al(MnFe)Si kancane kancane zibonisa izici ze-spheroidization.

Fig.3 Al(MnFe)Si isigaba ku-6082 ingxubevange

5. Umphumela wesistimu yokuguga yesisombululo ezicini zemishini

Ngemuva kwe-homogenization, isigaba senethiwekhi esinciphile ekuqaleni emngceleni wokusanhlamvu we-6082 alloy siyachithwa, esingathuthukisa izici zemishini ezibanzi zesampula. Ngesikhathi esifanayo, isigaba esizinzile esimelana nokushisa i-Al(MnFe)Si isigaba siphinde sibe ne-spheroidized, esingaphina kangcono ukuhlukaniswa. Lokhu kubonisa ukuthi ukusebenza okuphelele kwezinto kuzothuthukiswa ngemuva kokwelashwa kokushisa kwe-homogenization.

6. Isiphetho

6.1 I-6082 aluminium alloy ingot inama-dendrites athuthukiswe kahle kanye nenani elikhulu lezigaba zemvula ezingalingani enethiwekhi emingceleni yokusanhlamvu.

6.2 Ngemva kokwelashwa kwe-homogenization, ukubhekwa kwe-microscopic kwembula ukuthi inani lezigaba zemvula lancishiswa kakhulu, futhi usayizi wokusanhlamvu wanda ngokuhambisana. Ukuqedwa kokuhlukaniswa kanye nokuqedwa kwesigaba sokungalingani kwenzeke ku-ingot, futhi izinhlanganisela zenethiwekhi emingceleni yokusanhlamvu zahlakazwa kancane.

6.3 Uma kusakazwa ingxubevange engu-6082, isigaba semvula se-Al(MnFe)Si siyakhiqizwa. Lesi sigaba semvula siqukethe i-Mn element futhi sinokuzinza okuhle kwe-thermal. Njengoba inqubo ye-homogenization iqhubeka, izinhlayiya zesigaba semvula kancane kancane zibonisa izici ze-spheroidization. Lezi zinhlayiya zekhompiyutha eziqukethe i-Mn zihlakazeka ngokulinganayo futhi zishona ku-crystal.

I-6.4 Ngemva kokwelashwa kwe-homogenization, ukuqedwa kwesigaba esincishisiwe senethiwekhi kubonisa ukuthi ukusebenza okuphelele kwayo yonke ingot kuyathuthukiswa ngemva kokwelashwa kokushisa kwe-homogenization.

Isikhathi sokuthumela: Jun-08-2025