Izindlela zokuhlala zamaphrofayili e-aluminium asetshenziswa ekwakhiweni ngokuvamile zibandakanya ukukalwa kwesilinganiso kanye nokuxazululwa kwethiyori. Ukukalwa kwesilinganiso kuhlanganisa ukukala imikhiqizo yephrofayela ye-aluminium, okuhlanganisa izinto zokupakisha, nokubala inkokhelo ngokusekelwe esisindweni sangempela esiphindwe ngentengo ngethani. Ukukhokha okucatshangwayo kubalwa ngokuphindaphinda isisindo sethiyori samaphrofayili ngenani ngethani.

Ngesikhathi sokulungiswa kwesisindo, kunomehluko phakathi kwesisindo esikaliwe sangempela kanye nesisindo esibalwe ngokwethiyori. Kunezizathu eziningi zalo mehluko. Lesi sihloko sihlaziya kakhulu umehluko wesisindo obangelwa izici ezintathu: ukuhluka kogqinsi lwesisekelo samaphrofayili e-aluminium, umehluko wezendlalelo zokwelashwa okungaphezulu, nokuhluka kwezinto zokupakisha. Lesi sihloko sidingida indlela yokulawula lezi zici ukuze unciphise ukuchezuka.

1.Ukuhluka kwesisindo okubangelwa ukuhlukahluka kobukhulu bezinto eziyisisekelo

Kunomehluko phakathi kogqinsi lwangempela kanye nogqinsi lwethiyori yamaphrofayili, okuholela ekwehlukeni phakathi kwesisindo esikaliwe nesisindo sethiyori.

1.1 Isibalo sesisindo esisuselwe ekuhlukeni kogqinsi

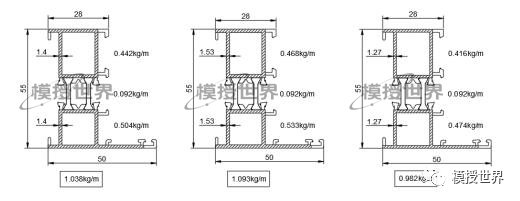

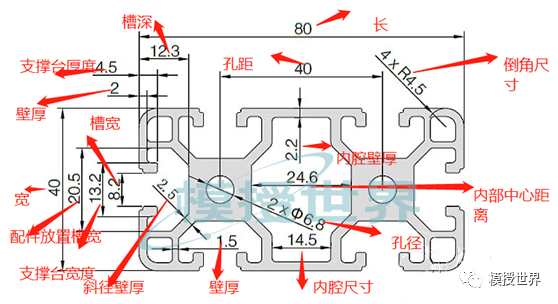

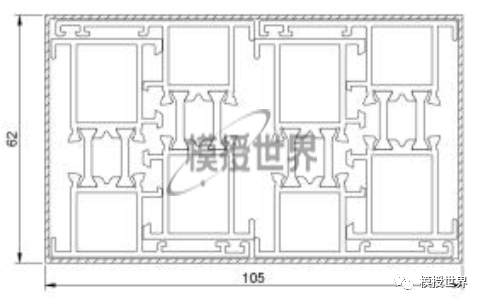

Ngokusho kwe-Chinese standard GB/T5237.1, kumaphrofayili anendingilizi yangaphandle engadluli ku-100mm nogqinsi lwamagama olungaphansi kuka-3.0mm, ukuchezuka okunembayo okuphezulu kungu-±0.13mm. Uma sithatha iphrofayili yefreyimu ewugqinsi ongu-1.4mm njengesibonelo, isisindo sethiyori imitha ngu-1.038kg/m. Ngokuchezuka okuhle kuka-0.13mm, isisindo imitha ngayinye singu-1.093kg/m, umehluko ongu-0.055kg/m. Ngokuchezuka okunegethivu okungu-0.13mm, isisindo imitha ngayinye singu-0.982kg/m, umehluko ongu-0.056kg/m. Uma ubala amamitha angu-963, kunomehluko ka-53kg ngethani, bheka uMdwebo 1.

Kumele kuqashelwe ukuthi umfanekiso ubheka kuphela ukuhluka kogqinsi kwesigaba sogqinsi esingu-1.4mm. Uma konke ukuhlukahluka kogqinsi kucatshangelwa, umehluko phakathi kwesisindo esikaliwe nesisindo sethiyori kungaba ngu-0.13/1.4*1000=93kg. Ukuba khona kokuhluka kogqinsi lwesisekelo samaphrofayili e-aluminium kunquma umehluko phakathi kwesisindo esikaliwe nesisindo sethiyori. Lapho ubukhulu bangempela busondela ekugqinsileni kwethiyori, kulapho isisindo esikaliwe sisondelana nesisindo sethiyori. Ngesikhathi sokukhiqizwa kwamaphrofayili e-aluminium, ubukhulu buyanda kancane kancane. Ngamanye amazwi, isisindo esikaliwe semikhiqizo ekhiqizwa isethi efanayo yesikhunta siqala silula kunesisindo sethiyori, bese siyafana, futhi kamuva siba sisinda kunesisindo sethiyori.

1.2 Izindlela zokulawula ukuchezuka

Izinga lokubunjwa kwephrofayili ye-aluminium iyisici esibalulekile ekulawuleni isisindo ngemitha ngayinye yamaphrofayili. Okokuqala, kuyadingeka ukulawula ngokuqinile ibhande elisebenzayo kanye nobukhulu bokucubungula kwezibunjwa ukuze uqinisekise ukuthi ubukhulu bokukhiphayo buhlangabezana nezidingo, ngokunemba okulawulwa ngaphakathi kwebanga elingu-0.05mm. Okwesibili, inqubo yokukhiqiza idinga ukulawulwa ngokuphatha isivinini se-extrusion ngendlela efanele kanye nokwenza ukunakekelwa ngemva kwenani elithile lokudlula kwesikhunta, njengoba kushiwo. Ukwengeza, isikhunta singathola ukwelashwa kwe-nitriding ukwandisa ubulukhuni bebhande elisebenzayo futhi kubambezele ukwanda kokuqina.

2.Isisindo Sethiyori Sezidingo Ezihlukene Zokuqina Kwezindonga

Ugqinsi lwamaphrofayili e-aluminium lunokubekezelelana, futhi amakhasimende ahlukene anezidingo ezihlukene zokuqina kodonga lomkhiqizo. Ngaphansi kwezidingo zokubekezelela ubukhulu bodonga, isisindo sethiyori siyahlukahluka. Ngokuvamile, kuyadingeka ukuthi kube nokuchezuka okuhle kuphela noma ukuchezuka okungekuhle kuphela.

2.1 Isisindo sethiyori Sokuchezuka Okuhle

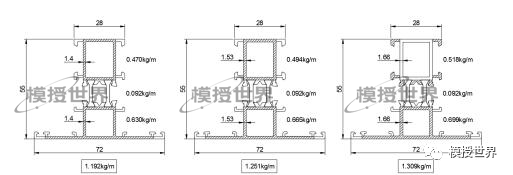

Kumaphrofayili e-aluminium anokuchezuka okuphozithivu ekujikeni kodonga, indawo ebalulekile yesisekelo esithwala umthwalo idinga ukujiya kodonga olulinganisiwe kungabi ngaphansi kuka-1.4mm noma u-2.0mm. Indlela yokubala yesisindo sethiyori ngokubekezelelana okuhle ukudweba umdwebo wokuchezuka ngogqinsi olugxile futhi ubale isisindo ngemitha. Isibonelo, kuphrofayela enobukhulu obungu-1.4mm bodonga kanye nokubekezelela okuhle okungu-0.26mm (ukubekezelelana okungekuhle okungu-0mm), ukujiya kodonga ekuchezukeni okumaphakathi kungu-1.53mm. Isisindo imitha yale phrofayili ngu-1.251kg/m. Isisindo sethiyori ngezinjongo zokukala kufanele sibalwe ngokusekelwe ku-1.251kg/m. Uma ukuqina kodonga lwephrofayili kuku--0mm, isisindo imitha ngayinye singu-1.192kg/m, futhi uma siku-+0.26mm, isisindo imitha ngayinye singu-1.309kg/m, bhekisa kuMfanekiso 2.

Ngokusekelwe kubukhulu bodonga obungu-1.53mm, uma kuphela isigaba esingu-1.4mm sinyuselwa ekuchezukeni okukhulu (ukuchezuka kwe-Z-max), umehluko wesisindo phakathi kokuchezuka okuhle kwe-Z-max kanye nogqinsi olumaphakathi lodonga ngu (1.309 – 1.251) * 1000 = 58kg. Uma bonke ukujiya kwezindonga kuku-Z-max ekuchezukeni (okuyinto engenakwenzeka kakhulu), umehluko wesisindo uzoba ngu-0.13/1.53 * 1000 = 85kg.

2.2 Isisindo sethiyori Sokuchezuka Okubi

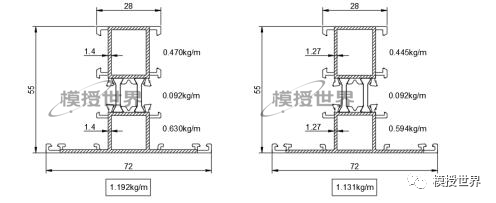

Kumaphrofayili e-aluminium, ukujiya kodonga akufanele kudlule inani elishiwo, okusho ukubekezelelana okungekuhle ekugqinsileni kodonga. Isisindo sethiyori kuleli cala kufanele sibalwe njengengxenye yokuchezuka okuyinegethivu. Isibonelo, kuphrofayela enobukhulu obungu-1.4mm bodonga kanye nokubekezelelana okungalungile okungu-0.26mm (ukubekezelelana okuhle okungu-0mm), isisindo sethiyori sibalwa ngokusekelwe kuhhafu wokubekezelela (-0.13mm), bheka uMfanekiso 3.

Ngobukhulu bodonga obungu-1.4mm, isisindo imitha ngayinye singu-1.192kg/m, kanti sinodonga oluyi-1.27mm, isisindo imitha singu-1.131kg/m. Umehluko phakathi kwalokhu okubili ngu-0.061kg/m. Uma ubude bomkhiqizo bubalwa njengethani elilodwa (838 amamitha), umehluko wesisindo uzoba ngu-0.061 * 838 = 51kg.

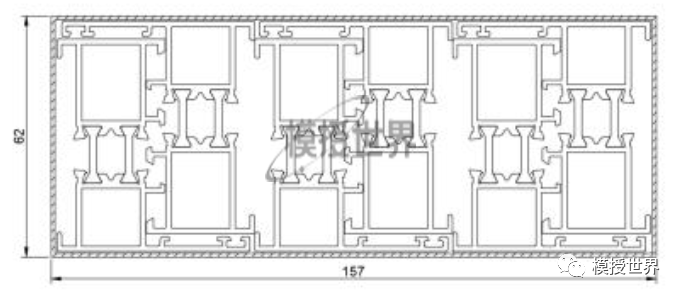

2.3 Indlela Yokubala Yesisindo Enobugqinsi Bodonga Oluhlukene

Kusuka emidwebeni engenhla, kungabonakala ukuthi lesi sihloko sisebenzisa ukunyuswa kokuqina kodonga noma ukuncishiswa lapho kubalwa ukujiya kwezindonga ezihlukene, kunokuzisebenzisa kuzo zonke izigaba. Izindawo ezigcwaliswe ngemigqa edayagonal kumdwebo zimele ubukhulu bodonga obungu-1.4mm, kuyilapho ezinye izindawo zihambisana nogqinsi lwezindonga ezisebenzayo namafins, ahluke ekujikeni kodonga ngokwezinga le-GB/T8478. Ngakho-ke, lapho kulungiswa ukushuba kodonga, ukugxila ikakhulukazi ekugqineni kodonga okuzisholo.

Ngokusekelwe ekuhlukeni kokuqina kodonga lwesikhunta ngesikhathi sokususwa kwempahla, kuqashelwa ukuthi zonke izinhlobo zezindonga zesikhunta ezisanda kwenziwa zinokuphambuka okungalungile. Ngakho-ke, ukucabangela kuphela izinguquko ekugqizeni kodonga lwegama kunikeza ukuqhathanisa okulandelanayo phakathi kwesisindo sokulinganisa kanye nesisindo sethiyori. Ubukhulu bodonga ezindaweni okungezona ezegama buyashintsha futhi bungabalwa ngokusekelwe kubukhulu bodonga obulinganiselwe ngaphakathi komkhawulo wokuchezuka komkhawulo.

Isibonelo, kumkhiqizo wefasitela nomnyango onobukhulu bodonga obungu-1.4mm, isisindo imitha singu-1.192kg/m. Ukuze ubale isisindo imitha ngayinye yobukhulu bodonga obungu-1.53mm, indlela yokubala elinganayo isetshenziswa: 1.192/1.4 * 1.53, okuholela esisindweni imitha ngayinye engu-1.303kg/m. Ngokufanayo, ngokuqina kodonga okungu-1.27mm, isisindo imitha ngayinye sibalwa njengo-1.192/1.4 * 1.27, okuholela esisindweni imitha ngayinye esingu-1.081kg/m. Indlela efanayo ingasetshenziswa kwezinye ubukhulu bodonga.

Ngokusekelwe esimeni sokujiya sodonga esingu-1.4mm, lapho kulungiswa konke ukujiya kwezindonga, umehluko wesisindo phakathi kwesisindo sesisindo nesisindo sethiyori cishe u-7% kuya ku-9%. Isibonelo, njengoba kukhonjisiwe kumdwebo olandelayo:

3.Umehluko Wesisindo Obangelwa Ukuqina Kwengqimba Yokwelashwa Okungaphezulu

Amaphrofayili e-aluminium asetshenziswa ekwakheni avame ukuphathwa nge-oxidation, i-electrophoresis, i-spray coating, i-fluorocarbon, nezinye izindlela. Ukwengezwa kwezingqimba zokwelashwa kwandisa isisindo samaphrofayili.

3.1 Ukwenyuka Kwesisindo Kumaphrofayili E-Oxidation kanye Ne-Electrophoresis

Ngemuva kokwelashwa okungaphezulu kwe-oxidation kanye ne-electrophoresis, ungqimba lwefilimu ye-oxide nefilimu ehlanganisiwe (ifilimu ye-oxide nefilimu yepende ye-electrophoretic) kwakheka, enobukhulu obungu-10μm kuya ku-25μm. Ifilimu yokwelapha engaphezulu yengeza isisindo, kodwa amaphrofayili e-aluminium alahlekelwa isisindo ngesikhathi senqubo yokwelashwa kwangaphambili. Ukwanda kwesisindo akubalulekile, ngakho-ke ukuguqulwa kwesisindo ngemva kwe-oxidation kanye nokwelashwa kwe-electrophoresis ngokuvamile akunakwa. Abakhiqizi abaningi be-aluminium bacubungula amaphrofayili ngaphandle kokwengeza isisindo.

3.2 Ukwenyuka Kwesisindo Kumaphrofayili Okwemboza Ngesifutho

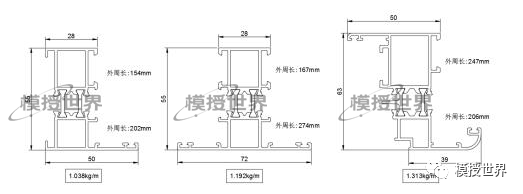

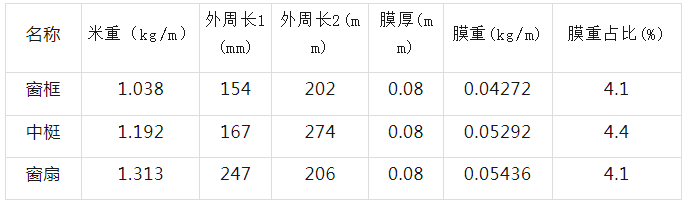

Amaphrofayili agcotshwe ngesifutho anongqimba lwempushana endaweni, enogqinsi olungekho ngaphansi kuka-40μm. Isisindo se-powder coating siyahlukahluka ngobukhulu. Izinga likazwelonke lincoma ukujiya okungu-60μm kuya ku-120μm. Izinhlobo ezahlukene zokumboza ngempushana zinezisindo ezihlukene zogqinsi lwefilimu efanayo. Emikhiqizweni ekhiqizwe ngobuningi njengamafreyimu ewindi, ama-mullions, namasashi ewindi, ukujiya kwefilimu eyodwa kufafazwa endaweni ezungezile, futhi idatha yobude be-peripheral ingabonakala kuMfanekiso 4. Ukukhula kwesisindo ngemva kokumbozwa kwesifutho samaphrofayela kungatholakala kuThebula 1.

Ngokusho kwedatha esethebulani, ukukhuphuka kwesisindo ngemuva kokufakwa kwesifutho seminyango namafasitela amaphrofayili angaba ngu-4% kuya ku-5%. Ngethani elilodwa lamaphrofayili, lilinganiselwa ku-40kg kuya ku-50kg.

3.3 Ukwenyuka Kwesisindo Kumaphrofayili E-Fluorocarbon Paint Spray Coating

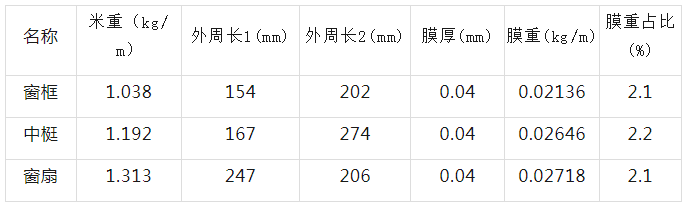

Ugqinsi oluyisilinganiso sokunamathela kumaphrofayili afakwe isifutho se-fluorocarbon alikho ngaphansi kuka-30μm kumajazi amabili, amajazi angu-40μm amajazi amathathu, kanye namajazi amane angu-65μm. Iningi lemikhiqizo egcotshwe ngopende we-fluorocarbon isebenzisa amajazi amabili noma amathathu. Ngenxa yezinhlobonhlobo zopende we-fluorocarbon, ukuminyana ngemva kokwelapha nakho kuyahlukahluka. Ukuthatha upende ojwayelekile we-fluorocarbon njengesibonelo, ukukhuphuka kwesisindo kungabonakala kuThebula lesi-2 elilandelayo.

Ngokusho kwedatha esethebulani, ukukhuphuka kwesisindo ngemuva kokufakwa kwesifutho seminyango namafasitela amaphrofayili anopende we-fluorocarbon angaba ngu-2.0% kuya ku-3.0%. Ngethani elilodwa lamaphrofayili, lilinganiselwa ku-20kg kuya ku-30kg.

3.4 Ukulawula Ukuqina Kwemikhiqizo Yokucwenga Yokwelapha Engaphezulu Eyimpushana Nemikhiqizo Yokufutha Kapende We-Fluorocarbon

Ukulawulwa kwesendlalelo sokumboza ku-powder kanye nemikhiqizo egcotshwe ngopende we-fluorocarbon kuyiphuzu elibalulekile lokulawula inqubo ekukhiqizeni, ikakhulukazi ukulawula ukuzinza nokufana kwempushana noma isifutho sikapende kusuka kusibhamu sokufuthwa, ukuqinisekisa ukushuba okufanayo kwefilimu kapende. Ekukhiqizeni kwangempela, ukushuba okweqile kwesendlalelo sokumboza kungesinye sezizathu zokumbozwa kwesifutho sesibili. Ngisho noma ingaphezulu lipholishiwe, isendlalelo sokumboza isifutho sisengaqina kakhulu. Abakhiqizi badinga ukuqinisa ukulawulwa kwenqubo yokumboza isifutho futhi baqinisekise ukushuba kwesifutho.

4.Umehluko Wesisindo Obangelwa Izindlela Zokupakisha

Amaphrofayili e-aluminium avame ukupakishwa ngokugoqa iphepha noma ukugoqa ifilimu, futhi isisindo sezinto zokupakisha siyahlukahluka kuye ngendlela yokupakisha.

4.1 Ukwenyuka Kwesisindo Ekugoqweni Kwamaphepha

Inkontileka ivamise ukucacisa umkhawulo wesisindo sokupakishwa kwamaphepha, ngokuvamile angeqi ku-6%. Ngamanye amazwi, isisindo sephepha ethoni elilodwa lamaphrofayili akufanele sidlule ku-60kg.

4.2 Ukwenyuka Kwesisindo Ekugoqweni Kwefilimu Ye-Shrink

Ukwenyuka kwesisindo ngenxa yokufakwa kwefilimu enciphayo kuvamise ukuba ngu-4%. Isisindo sefilimu ye-shrink ngethani elilodwa lamaphrofayili akufanele sidlule i-40kg.

4.3 Umthelela Wesitayela Sokupakisha Esisindweni

Umgomo wokupakishwa kwephrofayili ukuvikela amaphrofayili nokwenza lula ukuphatha. Isisindo sephakheji elilodwa lamaphrofayili kufanele sibe phakathi kuka-15kg kuya ku-25kg. Inani lamaphrofayili ngephakheji ngalinye lithinta iphesenti lesisindo sephakheji. Isibonelo, lapho amaphrofayili wefreyimu yefasitela ehlanganiswa ngamasethi ezicucu ezingu-4 ubude bamamitha angu-6, isisindo singama-25kg, futhi iphepha lokupakisha lilinganisa i-1.5kg, libalelwa ku-6%, libhekisela kuMfanekiso 5. Uma ihlanganiswe ngamasethi wezingcezu ezingu-6, isisindo singama-37kg, kanye nephepha lokupakisha ku-5 kg, i-akhawunti ye-akhawunti, i-akhawunti ye-akhawunti ye-4. 6.

Kusukela kuzibalo ezingenhla, kungabonakala ukuthi amaphrofayili amaningi ephaketheni, amancane amaphesenti esisindo sezinto zokupakisha. Ngaphansi kwenani elifanayo lamaphrofayili ngephakeji ngalinye, ukuphakama kwesisindo samaphrofayili, kuncane kwephesenti lesisindo sezinto zokupakisha. Abakhiqizi bangakwazi ukulawula inani lamaphrofayili ngephakheji ngalinye kanye nenani lezinto zokupakisha ukuhlangabezana nezidingo zesisindo ezishiwo kwinkontileka.

Isiphetho

Ngokusekelwe ekuhlaziyeni okungenhla, kukhona ukuchezuka phakathi kwesisindo sangempela sokukala samaphrofayili kanye nesisindo sethiyori. Ukuchezuka kokuqina kodonga kuyisizathu esiyinhloko sokuchezuka kwesisindo. Isisindo sesendlalelo sokwelashwa okungaphezulu singalawulwa kalula, futhi isisindo sezinto zokupakisha siyalawuleka. Umehluko wesisindo ongaphakathi kuka-7% phakathi kwesisindo nesisindo esibaliwe uhlangabezana nezidingo ezijwayelekile, futhi umehluko ongaphakathi kuka-5% umgomo womkhiqizi wokukhiqiza.

Ihlelwe nguMay Jiang evela kwaMAT Aluminium

Isikhathi sokuthumela: Sep-30-2023