I-6063 aluminium alloy ingeyochungechunge lwe-alloyed ephansi ye-Al-Mg-Si ekwazi ukumelana nokushisa. Inokusebenza okuhle kakhulu kokubumba kwe-extrusion, ukumelana nokugqwala okuhle kanye nezakhiwo ezibanzi zemishini. Ibuye isetshenziswe kabanzi embonini yezimoto ngenxa yombala wayo we-oxidation olula. Ngokusheshisa umkhuba wezimoto ezingasindi, ukusetshenziswa kwe-6063 aluminium alloy extrusion materials embonini yezimoto nakho kunyuke kakhulu.

I-microstructure kanye nezakhiwo zezinto ezikhishwe zithinteka yimiphumela ehlangene yejubane le-extrusion, izinga lokushisa lokukhipha kanye nesilinganiso se-extrusion. Phakathi kwabo, isilinganiso se-extrusion sinqunywa ngokuyinhloko ingcindezi ye-extrusion, ukusebenza kahle kokukhiqiza kanye nemishini yokukhiqiza. Lapho isilinganiso se-extrusion sincane, i-alloy deformation incane futhi ukulungiswa kwe-microstructure akubonakali; ukwandisa isilinganiso se-extrusion kungacwenga kakhulu okusanhlamvu, kuphule isigaba sesibili esimahhadla, kuthole i-microstructure efanayo, futhi kuthuthukise izakhiwo zemishini ye-alloy.

I-6061 kanye ne-6063 aluminium alloys yenzeka kabusha i-dynamic ngesikhathi senqubo yokukhipha. Lapho izinga lokushisa le-extrusion lihlala njalo, njengoba isilinganiso se-extrusion sikhula, usayizi wokusanhlamvu uyancipha, isigaba sokuqinisa sihlakazeka kahle, futhi amandla okuqina nokwelulwa kwe-alloy kwanda ngokufanele; kodwa-ke, njengoba isilinganiso se-extrusion sikhula, amandla okukhipha adingekayo ukuze inqubo ye-extrusion iphinde ikhule, ibangele umphumela omkhulu wokushisa, okwenza izinga lokushisa langaphakathi le-alloy likhuphuke, nokusebenza komkhiqizo kwehle. Lokhu kuhlolwa kufunda umphumela wesilinganiso se-extrusion, ikakhulukazi isilinganiso esikhulu se-extrusion, kusakhiwo se-microstructure kanye nezakhiwo zokukhanda ze-6063 aluminium alloy.

1 Izinto zokuhlola nezindlela

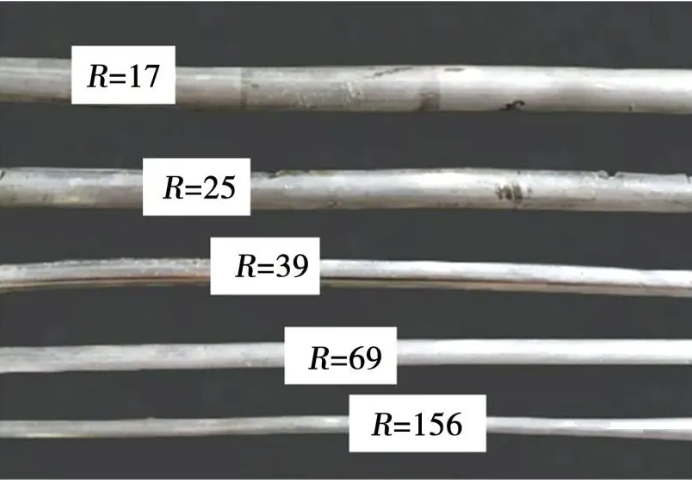

Izinto zokuhlola ziyi-alloy ye-aluminium engu-6063, futhi ukwakheka kwamakhemikhali kuboniswa kuThebula 1. Usayizi wangempela we-ingot ngu-Φ55 mm×165 mm, futhi ucutshungulwa ku-extrusion billet enosayizi ongu-Φ50 mm×150 mm ngemva kokwelashwa kwe-homogenization ku-560 ℃ ku-6 h. I-billet ifudunyezwa ku-470 ℃ futhi igcinwa ifudumele. Izinga lokushisa langaphambi kokushisa komgqomo we-extrusion ngu-420 ℃, futhi izinga lokushisa langaphambi kokushisa lesikhunta lingu-450 ℃. Uma isivinini sokukhipha (i-extrusion rod ezihambayo) V = 5 mm/s sihlala singashintshiwe, amaqembu angu-5 okuhlola okuhlukile kwe-extrusion ratio ayenziwa, futhi izilinganiso ze-extrusion R ziyi-17 (ezihambisana nobubanzi bomgodi wokufa D = 12 mm), 25 (D = 10 mm), 39 (D = 8 mm), 69 (D = 6 mm), 69 (D = 6 mm).

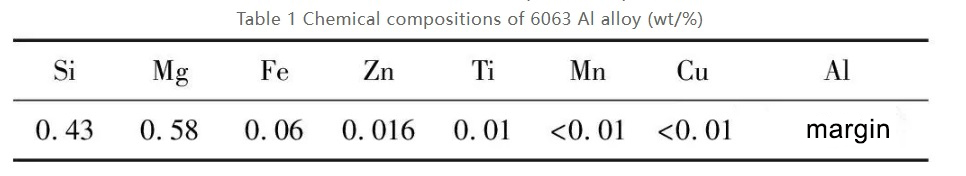

Ithebula 1 Ukwakheka kwamakhemikhali kwe-6063 Al alloy (wt/%)

Ngemva kokugaya i-sandpaper nokupholishwa ngomshini, amasampula e-metallographic aqoshwa nge-reagent ye-HF enengxenye yevolumu engu-40% cishe amasekhondi angu-25, futhi ukwakheka kwe-metallographic kwamasampuli kwabonwa kusibonakhulu se-LEICA-5000 optical. Isampuli yokuhlaziya ukuthungwa enosayizi ongu-10 mm×10 mm yasikwa maphakathi nengxenye ye-longitudinal ye-extruded rod, futhi ukugaywa komshini nokufakwa kwenziwa ukuze kukhishwe ungqimba olungaphezulu lwengcindezi. Izibalo zezigxobo ezingaphelele zezindiza ezintathu zekristalu {111}, {200}, kanye {220} zesampula zikalwe nge-X'Pert Pro MRD X-ray diffraction analyzer ye-PANalytical Company, futhi idatha yokuthungwa yacutshungulwa futhi yahlaziywa yi-X'Pert Data View kanye nesofthiwe ye-X'Pert Texture.

Isifanekiso esiqinile se-alloy ekhonjiwe sathathwa phakathi nendawo ye-ingot, futhi isifanekiso esiqinile sasikwa ngendlela ye-extrusion ngemva kokukhishwa. Usayizi wendawo yegeji bekungu-Φ4 mm×28 mm. Ukuhlolwa kwe-tensile kwenziwa kusetshenziswa umshini wokuhlola izinto ezibonakalayo we-SANS CMT5105 onesilinganiso esiqinile esingu-2 mm/min. Inani elimaphakathi lezibonelo ezintathu ezijwayelekile libalwe njengedatha yendawo yomshini. I-morphology yokuphuka kwezibonelo eziqinile kwaqashelwa kusetshenziswa isibonakhulu se-electron yokuskena ekhulisa kancane (Quanta 2000, FEI, USA).

2 Imiphumela nengxoxo

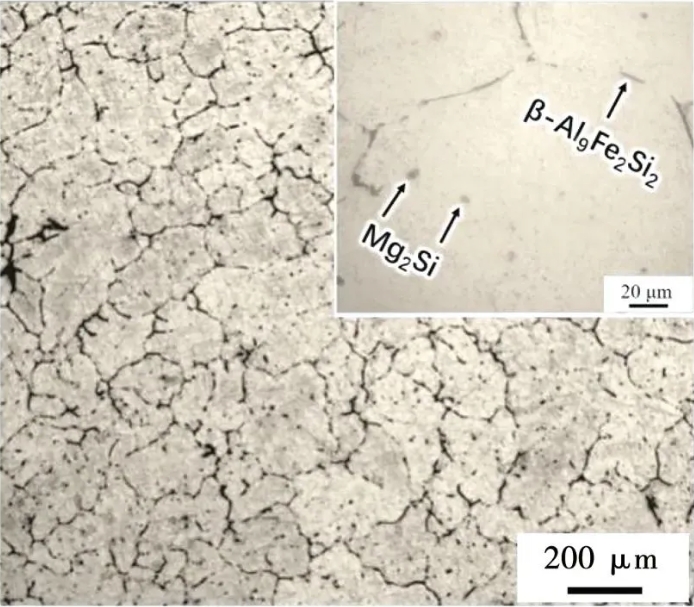

Umfanekiso 1 ubonisa i-metallographic microstructure ye-as-cast 6063 aluminium alloy ngaphambi nangemuva kokwelashwa kwe-homogenization. Njengoba kuboniswe kuMfanekiso 1a, izinhlamvu ze-α-Al ku-as-cast microstructure ziyahlukahluka ngobukhulu, inombolo enkulu yezigaba ze-reticular β-Al9Fe2Si2 ziqoqana emingceleni yokusanhlamvu, futhi inani elikhulu lezigaba ze-granular Mg2Si zikhona ngaphakathi kwezinhlamvu. Ngemva kokuthi ingot yenziwe i-homogenized ku-560 ℃ amahora angu-6, isigaba se-eutectic esingalingani phakathi kwe-alloy dendrites sancibilika kancane kancane, izakhi zengxubevange zancibilika ku-matrix, i-microstructure yayiyiyunifomu, futhi isilinganiso sikasayizi wokusanhlamvu sasicishe sibe ngu-125 μm (Umfanekiso 1b).

Ngaphambi kwe-homogenization

Ngemuva kokwelashwa kwe-uniformizing ku-600 ° C amahora angu-6

Fig.1 Isakhiwo se-Metallographic se-6063 aluminium alloy ngaphambi nangemva kokwelashwa kwe-homogenization

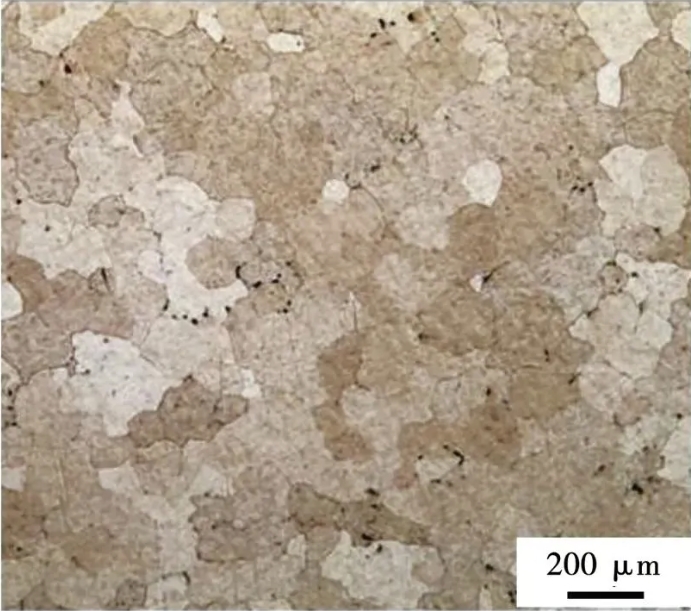

Umfanekiso 2 ubonisa ukubukeka kwamabha angu-6063 e-aluminium alloy anezilinganiso ezihlukene ze-extrusion. Njengoba kukhonjisiwe kuMfanekiso 2, ikhwalithi ephezulu ye-6063 aluminium alloy bar ekhishwe ngama-extrusion ratios ahlukene yinhle, ikakhulukazi uma isilinganiso se-extrusion senyuswa sibe ngu-156 (okuhambisana nesivinini sokuphuma kwe-bar extrusion esingu-48 m/min), azikho iziphambeko ze-extrusion njengokuqhekeka nokuxebuka, i-60 aluminium icwecwe ebusweni be-alloy 60 ne-alloy 3 enhle i-hot extrusion yakha ukusebenza ngaphansi kwesivinini esikhulu kanye nesilinganiso esikhulu se-extrusion.

Fig.2 Ukubukeka kwama-6063 aluminium alloy rods anezilinganiso ezahlukene ze-extrusion

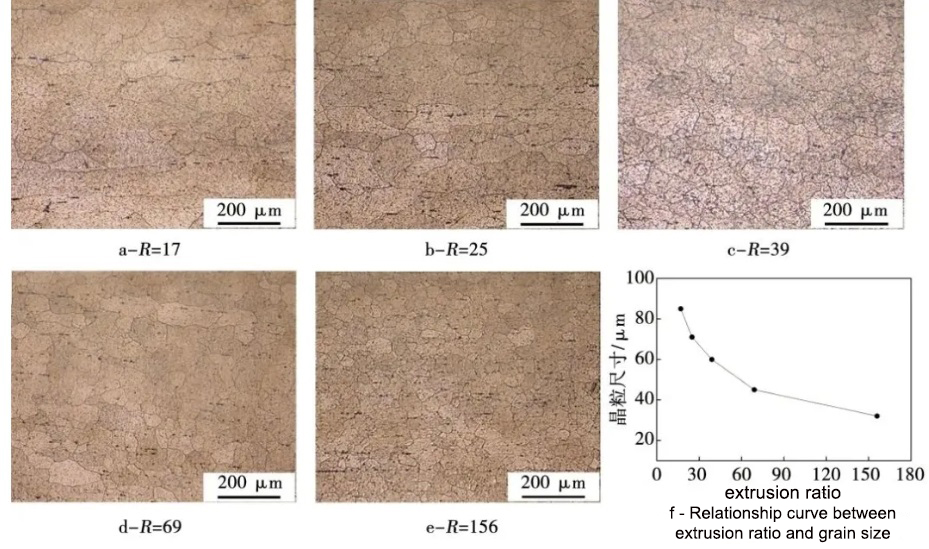

Umfanekiso 3 ubonisa i-metallographic microstructure yengxenye yobude bebha ye-aluminium engu-6063 enezilinganiso ezihlukene ze-extrusion. Isakhiwo sokusanhlamvu sebha enezilinganiso ezihlukene ze-extrusion sibonisa amadigri ahlukene obude noma bokucwengwa. Lapho isilinganiso se-extrusion singu-17, okusanhlamvu kwangempela kunwetshwa eduze kwesiqondiso se-extrusion, kuhambisane nokwakheka kwenani elincane lezinhlamvu ezivuselelwe kabusha, kodwa okusanhlamvu kusengamaholoholo, ngesilinganiso sokusanhlamvu esingaba ngu-85 μm (Umfanekiso 3a); lapho isilinganiso se-extrusion singama-25, okusanhlamvu kudonswa kancane kancane, inani lezinhlamvu ezivuselelwe kabusha liyakhula, futhi usayizi wokusanhlamvu ojwayelekile uyancipha ube ngu-71 μm (Umfanekiso 3b); lapho isilinganiso se-extrusion singama-39, ngaphandle kwenani elincane lezinhlamvu ezikhubazekile, i-microstructure ngokuyisisekelo yakhiwe ngezinhlamvu ezilinganayo ze-recrystallized zosayizi ongalingani, ezinosayizi ojwayelekile wokusanhlamvu ongaba ngu-60 μm (Figure 3c); lapho isilinganiso se-extrusion singama-69, inqubo yokuvuselela kabusha eguquguqukayo isiqediwe ngokuyisisekelo, izinhlamvu zangempela ezimahhadla ziguqulelwe ngokuphelele zibe yizinhlamvu ezihlelwe kabusha ezihlelwe ngendlela efanayo, futhi usayizi wokusanhlamvu ojwayelekile ucwengiwe ube ngu-41 μm (Umfanekiso 3d); lapho isilinganiso se-extrusion singu-156, ngokuqhubeka okugcwele kwenqubo ye-recrystallization ashukumisayo, i-microstructure ifana kakhulu, futhi usayizi wokusanhlamvu uhlanjululwe kakhulu mayelana ne-32 μm (Umfanekiso 3e). Ngokukhula kwe-extrusion ratio, inqubo ye-recrystallization eguquguqukayo iqhubeka ngokugcwele, i-alloy microstructure iba yinto efanayo, futhi usayizi wokusanhlamvu uhlanjululwa kakhulu (Umfanekiso 3f).

Umdwebo 3 Ukwakheka kwe-Metallographic nosayizi wohlamvu wengxenye yobude be-6063 ye-aluminium alloy rods enezilinganiso ezihlukene ze-extrusion

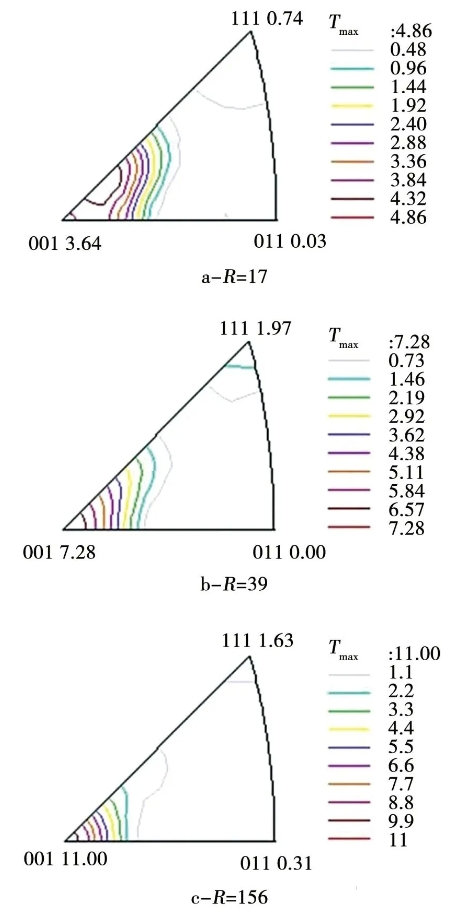

Umfanekiso 4 ubonisa izibalo zezigxobo eziphambene zamabha we-aluminium alloy angu-6063 anezilinganiso ezihlukene ze-extrusion eduze kwesikhombisi-ndlela se-extrusion. Kungabonakala ukuthi ama-microstructures we-alloy bar anezilinganiso ezahlukene ze-extrusion wonke akhiqiza ukuma okukhethekile okucacile. Uma isilinganiso se-extrusion siyi-17, ukuthungwa okubuthakathaka <115>+<100> kuyakhiwa (Umfanekiso 4a); lapho isilinganiso se-extrusion singama-39, izingxenye zokuthungwa zinamandla kakhulu <100> ukuthungwa kanye nenani elincane lokuthungwa okubuthakathaka <115> (Umfanekiso 4b); uma isilinganiso se-extrusion siyi-156, izingxenye zokuthungwa zingu-<100> ukuthungwa okunamandla anyuke kakhulu, kuyilapho <115> ukuthungwa kunyamalala (Umfanekiso 4c). Ucwaningo lubonise ukuthi ama-cubic metals agxile ebusweni ikakhulukazi enza ukwakheka kwentambo engu-<111> kanye <100> ngesikhathi sokukhipha nokudweba. Uma ukuthungwa sekwenziwe, izinga lokushisa legumbi lemishini ye-alloy libonisa i-anisotropy esobala. Amandla okuthungwa ayanda ngokukhula kwe-extrusion ratio, okubonisa ukuthi inani lezinhlamvu endaweni ethile yekristalu elihambisana nesiqondiso se-extrusion ku-alloy liyakhula kancane kancane, futhi amandla e-longitudinal tensile we-alloy ayanda. Izindlela zokuqinisa ze-6063 aluminium alloy hot extrusion materials zihlanganisa ukuqinisa okusanhlamvu okuhle, ukuqinisa ukususwa, ukuqinisa ukuthungwa, njll. Ngaphakathi kobubanzi bemingcele yenqubo esetshenziswe kulolu cwaningo lokuhlola, ukukhulisa isilinganiso se-extrusion kunomphumela okhuthazayo ezindleleni zokuqinisa ezingenhla.

Umdwebo we-Fig.4 Reverse pole diagram ye-6063 aluminium alloy rods enezilinganiso ezihlukene ze-extrusion eduze kwe-extrusion direction

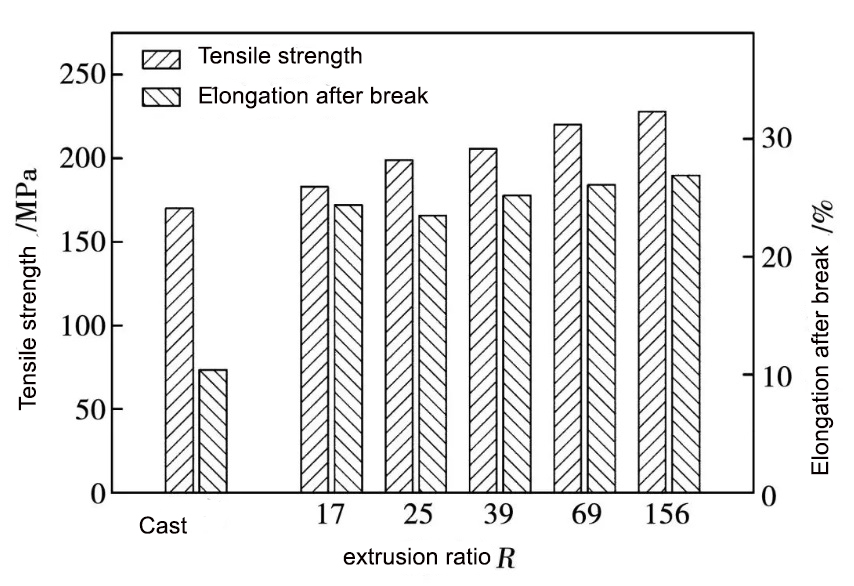

Umfanekiso 5 uyi-histogram yezakhiwo eziqinile ze-6063 aluminium alloy ngemva kokuguqulwa kwezilinganiso ezahlukene ze-extrusion. Amandla aqinile we-cast alloy yi-170 MPa futhi ubude bungu-10.4%. Amandla aqinile kanye nokwelulwa kwengxubevange ngemva kokukhishwa kuthuthukiswa kakhulu, futhi amandla okuqina nokwelula kukhuphuka kancane kancane ngokunyuka kwe-extrusion ratio. Lapho isilinganiso se-extrusion singu-156, amandla aqinile kanye nokwelulwa kwe-alloy kufinyelela inani eliphakeme, elingu-228 MPa no-26.9%, ngokulandelana, okungama-34% aphezulu kunamandla okudonsa we-alloy futhi cishe ngo-158% ngaphezu kwe-elongation. Amandla aqinile we-6063 aluminium alloy atholwe ngesilinganiso esikhulu se-extrusion aseduze nenani lamandla e-tensile (240 MPa) atholwe ngama-4-pass alinganayo we-angular extrusion (ECAP), ephakeme kakhulu kunevelu yamandla e-tensile (171.1 MPa) etholwe yi-1-pass ECAP extrusion ye-6063 aluminium alloy. Kungabonakala ukuthi isilinganiso esikhulu se-extrusion singathuthukisa izakhiwo zemishini ye-alloy ngezinga elithile.

Ukuthuthukiswa kwezakhiwo zemishini ye-alloy nge-extrusion ratio ikakhulukazi kuvela ekuqinisweni kokucwenga okusanhlamvu. Njengoba isilinganiso se-extrusion sikhula, okusanhlamvu kuyacwengwa futhi ukuminyana kokuhlukaniswa kuyanda. Imingcele eyengeziwe yokusanhlamvu endaweni ngayinye ingavimbela ngokuphumelelayo ukunyakaza kokuhlukaniswa, kuhlanganiswe nokunyakaza okuhlangene kanye nokugoqa kokuxoshwa, ngaleyo ndlela kuthuthukise amandla e-alloy. Izinhlamvu ezinhle kakhulu, imingcele yokusanhlamvu ihlukumeza kakhulu, futhi ukuguqulwa kwepulasitiki kungahlakazwa ezinhlamvu eziningi, ezingahambisani nokwakheka kwemifantu, ingasaphathwa eyokusakazwa kwemifantu. Amandla engeziwe angamuncwa ngesikhathi senqubo yokuphuka, ngaleyo ndlela enze ngcono ipulasitiki ye-alloy.

Izakhiwo ze-Fig.5 Tensile ze-6063 aluminium alloy ngemva kokusakazwa nokukhishwa

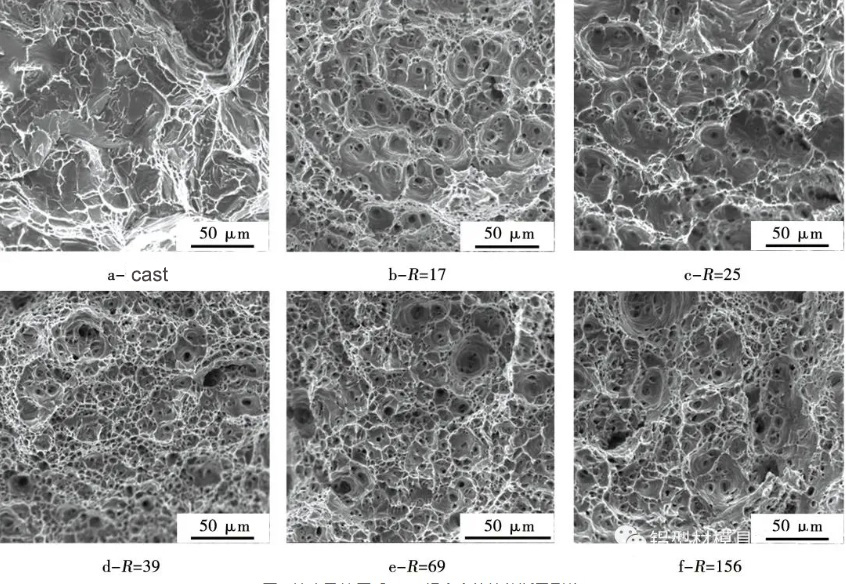

I-tensile fracture morphology ye-alloy ngemva kokuguqulwa ngezilinganiso ezihlukene ze-extrusion kuboniswe kuMfanekiso 6. Awekho ama-dimples atholakala ku-morphology yokuphuka kwesampula ye-as-cast (Umfanekiso 6a), futhi ukuphuka kwakhiwe ikakhulukazi izindawo eziyisicaba kanye nemiphetho edabukisayo, ebonisa ukuthi i-tensile fractures mechanism of the main-fracture yayiyi-fracture fracture ngokuyinhloko. I-morphology ye-fracture ye-alloy ngemva kwe-extrusion ishintshile kakhulu, futhi ukuphuka kuhlanganiswe nenani elikhulu lama-dimples alinganayo, okubonisa ukuthi umshini wokuphuka we-alloy ngemva kokukhishwa kwe-extrusion ushintshile kusuka ku-brittle fracture kuya ku-ductile fracture. Uma isilinganiso se-extrusion sisincane, ama-dimples awashoni futhi usayizi we-dimple mkhulu, futhi ukusabalalisa akulingani; njengoba isilinganiso se-extrusion sikhula, inani lama-dimples liyakhula, ubukhulu be-dimple buncane futhi ukusabalalisa kufana (Umfanekiso 6b ~ f), okusho ukuthi i-alloy ine-plasticity engcono, ehambisana nemiphumela yokuhlola izakhiwo zemishini ngenhla.

3 Isiphetho

Kulesi sivivinyo, imiphumela yezilinganiso ezihlukene ze-extrusion ku-microstructure kanye nezakhiwo ze-6063 aluminium alloy yahlaziywa ngaphansi kwesimo sokuthi usayizi we-billet, izinga lokushisa le-ingot kanye nesivinini sokukhipha kuhlale kungashintshiwe. Iziphetho zimi kanje:

1) Ukuvuselelwa kabusha kwe-Dynamic kwenzeka ku-6063 aluminium alloy ngesikhathi sokukhipha okushisayo. Ngokukhula kwesilinganiso se-extrusion, okusanhlamvu kucwengwa ngokuqhubekayo, futhi izinhlamvu ezinwetshwa eduze kwendlela ye-extrusion ziguqulwa zibe yizinhlamvu ezilinganayo, futhi amandla <100> wokuthungwa kwentambo ayanda ngokuqhubekayo.

I-2) Ngenxa yomphumela wokuqinisa okusanhlamvu okuhle, izakhiwo zemishini ye-alloy zithuthukiswa ngokunyuka kwe-extrusion ratio. Ngaphakathi kobubanzi bemingcele yokuhlola, lapho isilinganiso se-extrusion singama-156, amandla aqinile kanye nokuphakama kwe-alloy kufinyelela kumanani aphezulu we-228 MPa no-26.9%, ngokulandelana.

Fig.6 I-Tensile fracture morphologies ye-6063 aluminium alloy ngemva kokusakazwa nokukhishwa

3) I-morphology yokuphuka yesampula ye-as-cast yakhiwe izindawo eziyisicaba kanye nemiphetho yokudabula. Ngemuva kokukhishwa, ukuphuka kuhlanganiswe nenani elikhulu lama-dimples alinganayo, futhi indlela yokuphuka iguqulwa isuka ku-brittle fracture kuya ku-ductile fracture.

Isikhathi sokuthumela: Nov-30-2024