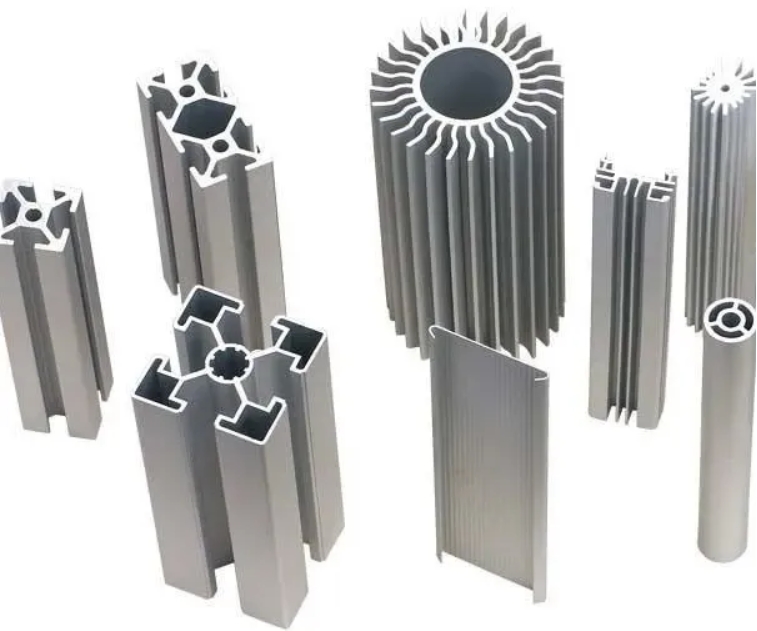

I-Aluminiyamu iyinto evame ukucaciswa kaningi yamaphrofayili e-extrusion kanye nomumo ngoba inezinto eziwumshini eziyenza ifaneleke ukwenza nokubumba insimbi kusuka ezigabeni ze-billet. I-ductility ephezulu ye-aluminium isho ukuthi insimbi ingakhiwa kalula ibe yiziqephu ezihlukene ngaphandle kokusebenzisa amandla amaningi enkambweni yomshini noma yokwakha, futhi i-aluminiyamu nayo inephuzu lokuncibilika elicishe libe uhhafu wensimbi evamile. Womabili la maqiniso asho ukuthi inqubo yephrofayili ye-aluminium ye-extrusion ingamandla aphansi, okunciphisa izindleko zamathuluzi nezokukhiqiza. Okokugcina, i-aluminium nayo inamandla aphezulu esilinganisweni sesisindo, okwenza kube ukukhetha okuhle kakhulu kwezicelo zezimboni.

Njengomkhiqizo wenqubo ye-extrusion, kuhle, imigqa ecishe ingabonakali kwesinye isikhathi ingavela ebusweni bephrofayili. Lokhu kuwumphumela wokwakhiwa kwamathuluzi asizayo ngesikhathi sokukhipha, futhi ukwelashwa okwengeziwe kwendawo kungacaciswa ukususa le migqa. Ukuze kuthuthukiswe ukuphela kwengxenye yephrofayili, imisebenzi eminingana yesibili yokwelashwa kwendawo efana nokugaywa kobuso ingenziwa ngemva kwenqubo eyinhloko yokwenza i-extrusion. Le misebenzi yomshini ingacaciswa ukuze kuthuthukiswe ijiyomethri yendawo ukuze kuthuthukiswe ingxenye yephrofayili ngokunciphisa ubulukhuni obuphelele bobuso bephrofayela ekhishwe. Lokhu kwelashwa kuvame ukucaciswa ezinhlelweni lapho kudingeka khona ukumisa okunembile kwengxenye noma lapho ukukhwelana kufanele kulawulwe ngokuqinile.

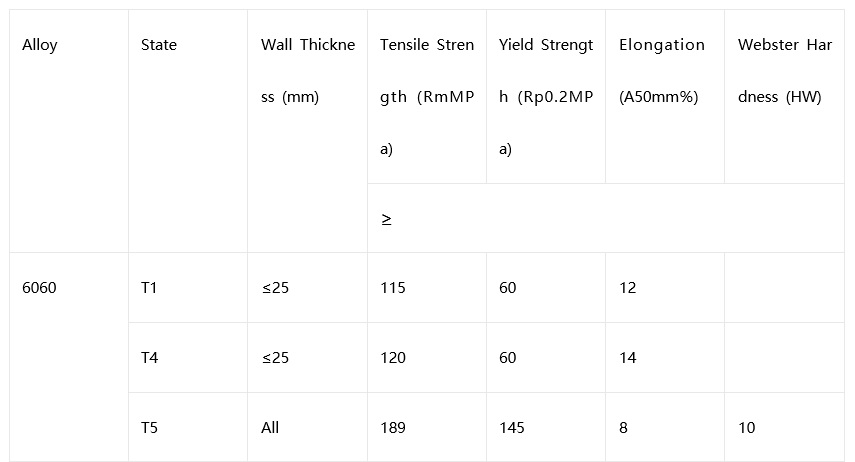

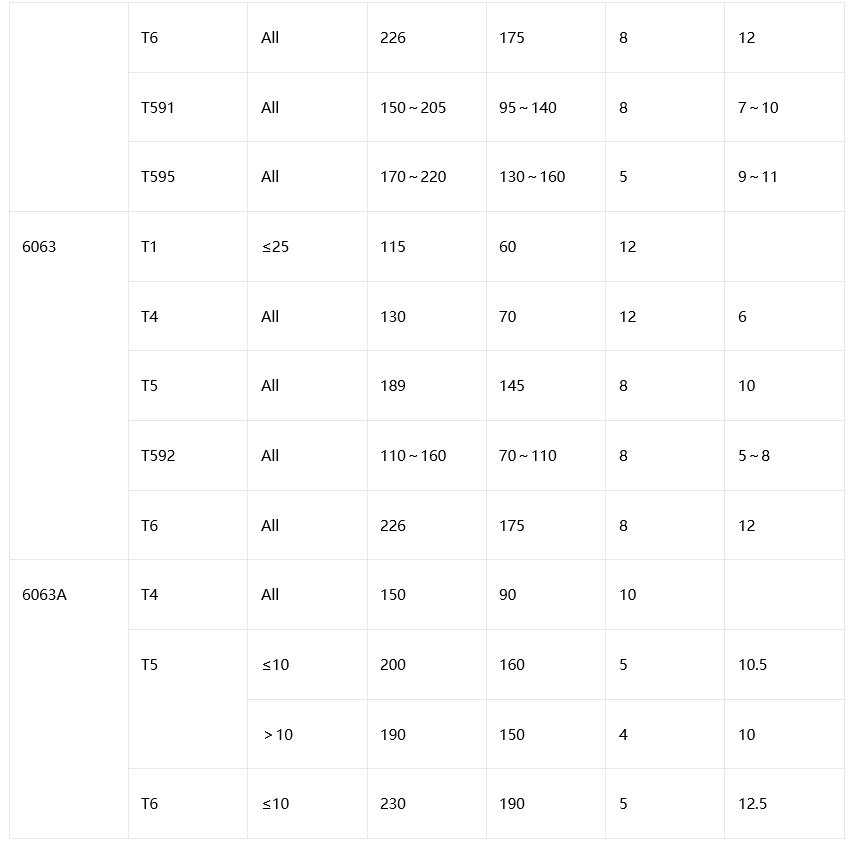

Sivame ukubona ikholomu yezinto ezibonakalayo ezimakwe ngokuthi 6063-T5/T6 noma 6061-T4, njll. I-6063 noma 6061 kulolu phawu uhlobo lwephrofayili ye-aluminium, futhi i-T4/T5/T6 yisimo sephrofayela ye-aluminium. Uyini-ke umehluko phakathi kwabo?

Isibonelo: Kalula nje, iphrofayili ye-aluminium engu-6061 inamandla angcono nokusebenza kokusika, ngokuqina okuphezulu, i-weldability enhle nokumelana nokugqwala; Iphrofayili ye-aluminium engu-6063 ine-plasticity engcono, engenza impahla ifinyelele ukunemba okuphezulu, futhi ngesikhathi esifanayo inamandla aphezulu okuqinile namandla okukhiqiza, ibonisa ukuqina okungcono kokuphuka, futhi inamandla aphezulu, ukumelana nokugqoka, ukumelana nokugqwala nokumelana nokushisa okuphezulu.

Isimo se-T4:

ukwelashwa kwesixazululo + ukuguga kwemvelo, okungukuthi, iphrofayili ye-aluminium ipholile ngemva kokukhishwa kwe-extruder, kodwa ingagugi esithandweni sokuguga. Iphrofayili ye-aluminium engakaze ibe mdala inobulukhuni obuphansi ngokuqhathaniswa nokukhubazeka okuhle, elungele ukugoba kamuva nokunye ukucutshungulwa kokuguqulwa.

Isimo se-T5:

Ukwelashwa kwesixazululo + ukuguga okufakelwayo okungaphelele, okungukuthi, ngemuva kokupholisa umoya ngemuva kokukhishwa kwe-extrusion, bese kudluliselwa esithandweni sokuguga ukuze sifudumale cishe ngama-degree angu-200 amahora angu-2-3. I-aluminium kulesi simo inobunzima obuphakeme kakhulu kanye nezinga elithile lokukhubazeka. Yilona elisetshenziswa kakhulu ezindongeni zamakhethini.

Isimo se-T6:

Ukwelashwa kwesixazululo + ukuguga okuphelele kokwenziwa, okungukuthi, ngemva kokupholisa amanzi ngemva kokukhishwa kwe-extrusion, ukuguga okwenziwa ngemva kokucisha kungaphezu kwezinga lokushisa le-T5, futhi isikhathi sokufakelwa siphinde sibe side, ukuze kuzuzwe isimo sobulukhuni obuphakeme, esifanele izikhathi ezinezidingo eziphakeme kakhulu zobulukhuni bezinto ezibonakalayo.

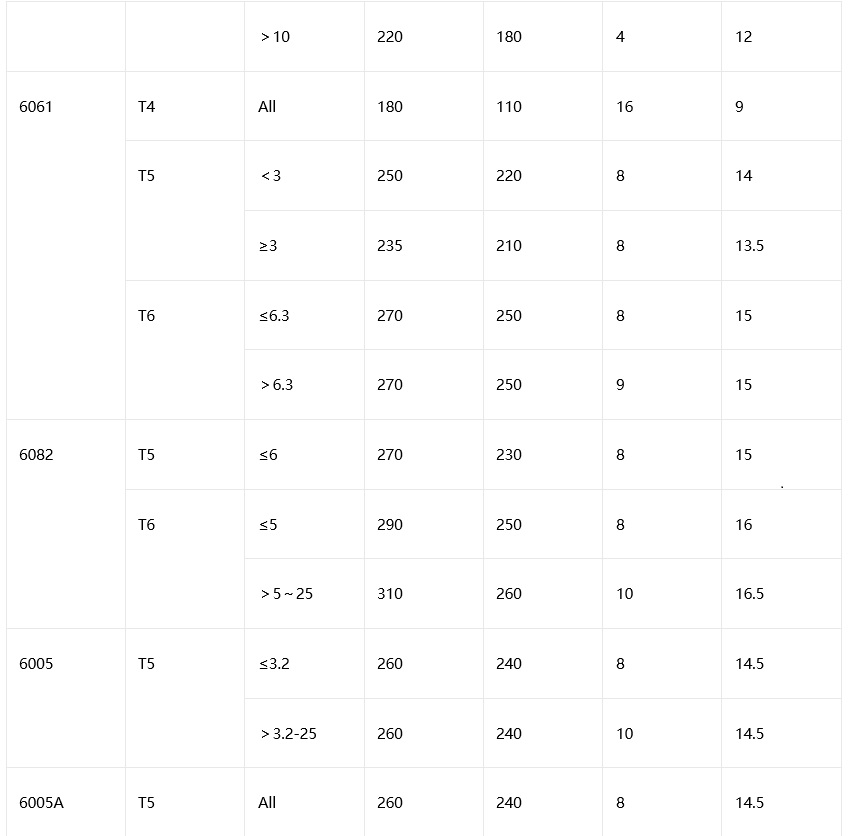

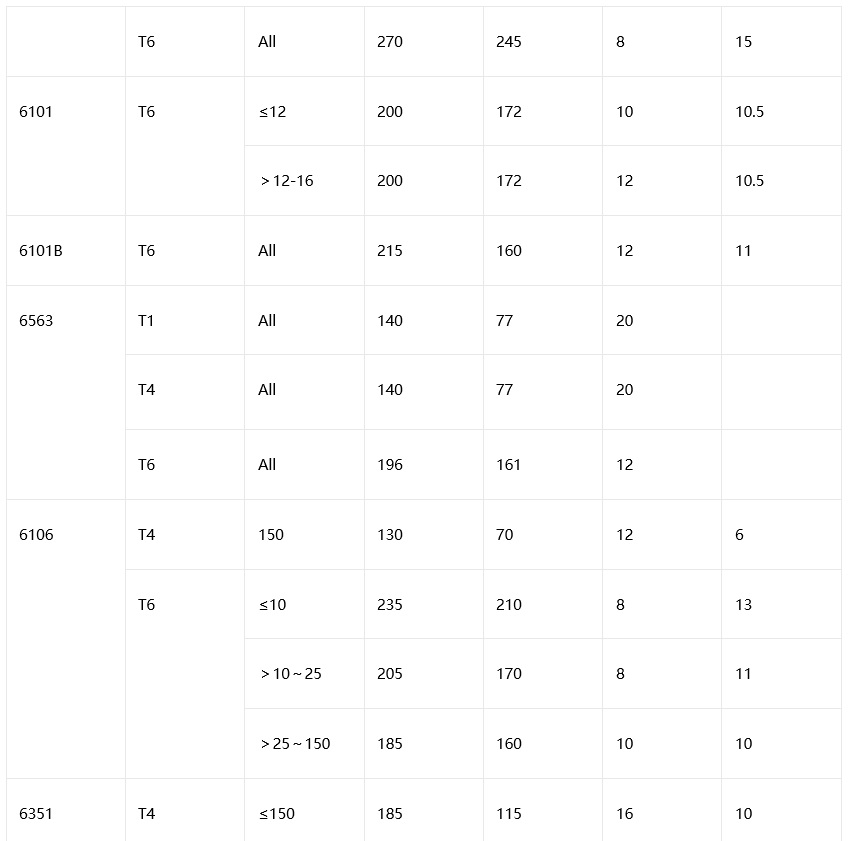

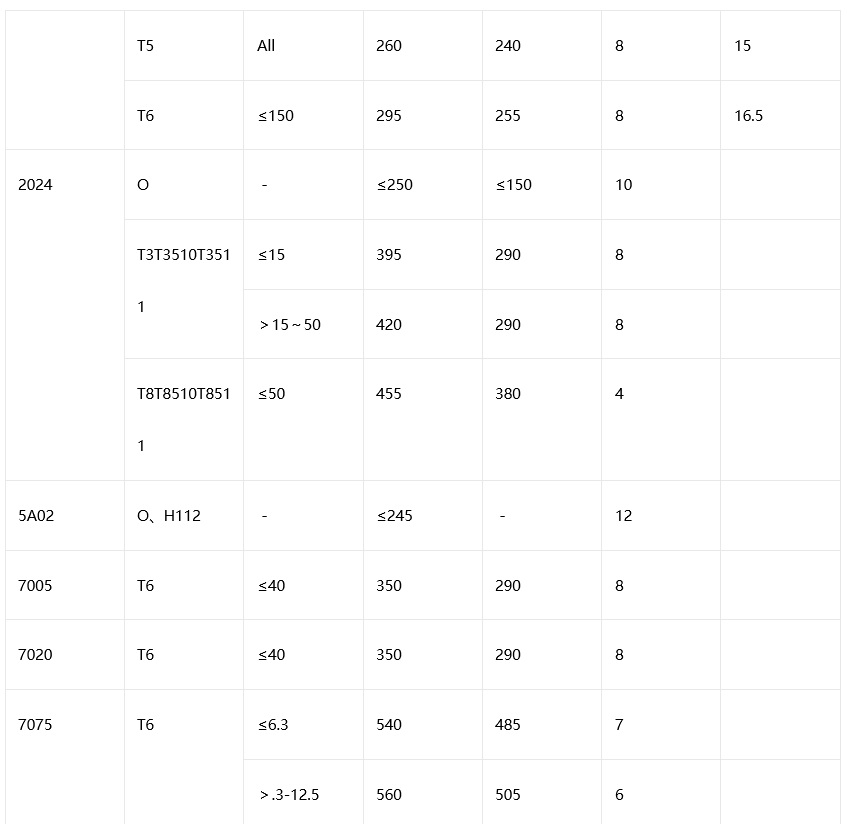

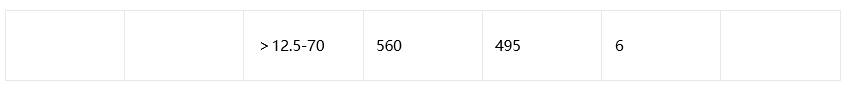

Izakhiwo zemishini zamaphrofayili e-aluminium wezinto ezahlukahlukene nezimo ezahlukahlukene zichazwe kuthebula elingezansi:

Amandla okukhiqiza:

Kungumkhawulo wesivuno sezinto zensimbi lapho zithela, okungukuthi, ingcindezi ephikisana nokuguqulwa kwepulasitiki encane. Ngezinto zensimbi ezingenayo isivuno esisobala, inani lokucindezeleka elikhiqiza u-0.2% we-residual deformation libalulwe njengomkhawulo walo wesivuno, okubizwa ngokuthi umkhawulo wesivuno esinemibandela noma amandla esivuno. Amandla angaphandle amakhulu kunalo mkhawulo azobangela ukuthi izingxenye zehluleke unomphela futhi azikwazi ukubuyiselwa.

Amandla okuqina:

Lapho i-aluminium ikhiqiza ngezinga elithile, ikhono layo lokumelana nokuguquka liyanda futhi ngenxa yokuhlelwa kabusha kwezinhlamvu zangaphakathi. Nakuba i-deformation ikhula ngokushesha ngalesi sikhathi, ingakhula kuphela ngokunyuka kokucindezeleka kuze kube yilapho ukucindezeleka kufinyelela inani eliphezulu. Ngemuva kwalokho, ikhono lephrofayili lokumelana ne-deformation liyancipha kakhulu, futhi ukuguqulwa okukhulu kwepulasitiki kwenzeka endaweni ebuthakathaka. I-cross-section ye-specimen lapha iyancipha ngokushesha, futhi ukugoqa kwenzeka kuze kube yilapho kuphuka.

Ukuqina kwe-Webster:

Umgomo oyisisekelo wobulukhuni beWebster ukusebenzisa inaliti yokucindezela ecishiwe yomumo othile ukuze ucindezele ebusweni besampula ngaphansi kwamandla entwasahlobo evamile, futhi uchaze ukujula okungu-0.01MM njengeyunithi yobulukhuni beWebster. Ukuqina kwento kuhambisana ngokuphambene nokujula kokungena. Lapho ukungena kungashoni, kuyanda ubulukhuni, futhi ngokuphambene nalokho.

I-deformation yepulasitiki:

Lolu wuhlobo lokuwohloka ongeke ukwazi ukuzitholela lona. Lapho izinto zokwakha zobunjiniyela kanye nezingxenye zilayishwa ngale kwebanga le-elastic deformation, ukuguqulwa okuhlala njalo kuzokwenzeka, okungukuthi, ngemva kokususwa komthwalo, ukuguqulwa okungenakuhlehliswa noma ukuguqulwa okusele kuzokwenzeka, okuwukuguqulwa kwepulasitiki.

Isikhathi sokuthumela: Oct-09-2024