Ingxenye.1 umklamo onengqondo

Isikhunta siklanywe ngokuyinhloko ngokwezidingo zokusetshenziswa, futhi isakhiwo saso ngezinye izikhathi asikwazi ukuba nengqondo ngokuphelele futhi silingane ngokulinganayo. Lokhu kudinga ukuthi umklami athathe izinyathelo eziphumelelayo lapho eklama isikhunta ngaphandle kokuthinta ukusebenza kwesikhunta, futhi azame ukunaka inqubo yokukhiqiza, ukucabangela kwesakhiwo kanye nokulinganisa kokuma kwejometri.

(1) Zama ukugwema amakhona acijile kanye nezingxenye ezinomehluko omkhulu wokuqina

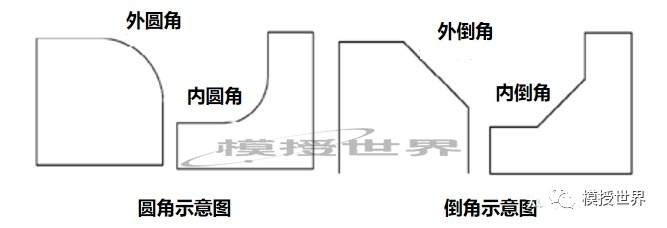

Kufanele kube noshintsho olubushelelezi lapho kuhlangana khona izingxenye eziwugqinsi nezincane zesikhunta. Lokhu kunganciphisa ngokuphumelelayo umehluko wokushisa we-cross-section of the mold, ukunciphisa ukucindezeleka okushisayo, futhi ngesikhathi esifanayo kunciphise ukungahambisani nesikhathi sokuguqulwa kwezicubu engxenyeni yesiphambano, futhi kunciphise ukucindezeleka kwezicubu. Umfanekiso 1 ubonisa ukuthi isikhunta sithatha i-transition fillet kanye ne-transition cone.

(2) Khulisa ngokufanelekile izimbobo zenqubo

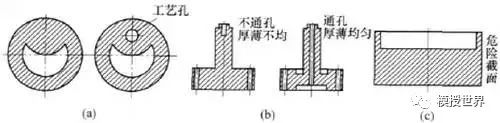

Kwezinye izibunjwa ezingakwazi ukuqinisekisa iyunifomu kanye nesigaba sesiphambano esilinganayo, kuyadingeka ukushintsha imbobo engadluleli ibe yimbobo edlulayo noma ukwandisa izimbobo ezithile zenqubo ngendlela efanele ngaphandle kokuphazamisa ukusebenza.

Umfanekiso 2a ubonisa ifa elinesikhala esincane, esizokhubazeka njengoba kukhonjiswa umugqa wamachashazi ngemva kokucisha. Uma izimbobo ezimbili zenqubo zingangezwa ekwakhiweni (njengoba kuboniswe ku-Figure 2b), umehluko wokushisa we-cross-section ngesikhathi senqubo yokucisha uyancipha, ukucindezeleka okushisayo kuyancipha, futhi ukuguqulwa kuthuthukiswe kakhulu.

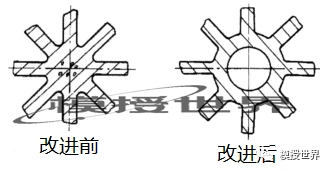

(3) Sebenzisa izakhiwo ezivaliwe nezilinganayo ngangokunokwenzeka

Uma ukubunjwa kwesikhunta kuvuliwe noma ku-asymmetrical, ukusatshalaliswa kwengcindezi ngemva kokucisha akulingani futhi kulula ukukhubaza. Ngakho-ke, ekubunjweni okujwayelekile okugobayo, ukuqinisa kufanele kwenziwe ngaphambi kokucisha, bese kunqunywa ngemva kokucisha. I-workpiece ye-trough eboniswe kuMfanekiso 3 ekuqaleni yayikhubazekile ku-R ngemva kokucisha, futhi yaqiniswa (ingxenye echanyuselwe kuMfanekiso 3), ingavimbela ngokuphumelelayo ukucisha ukuguquka.

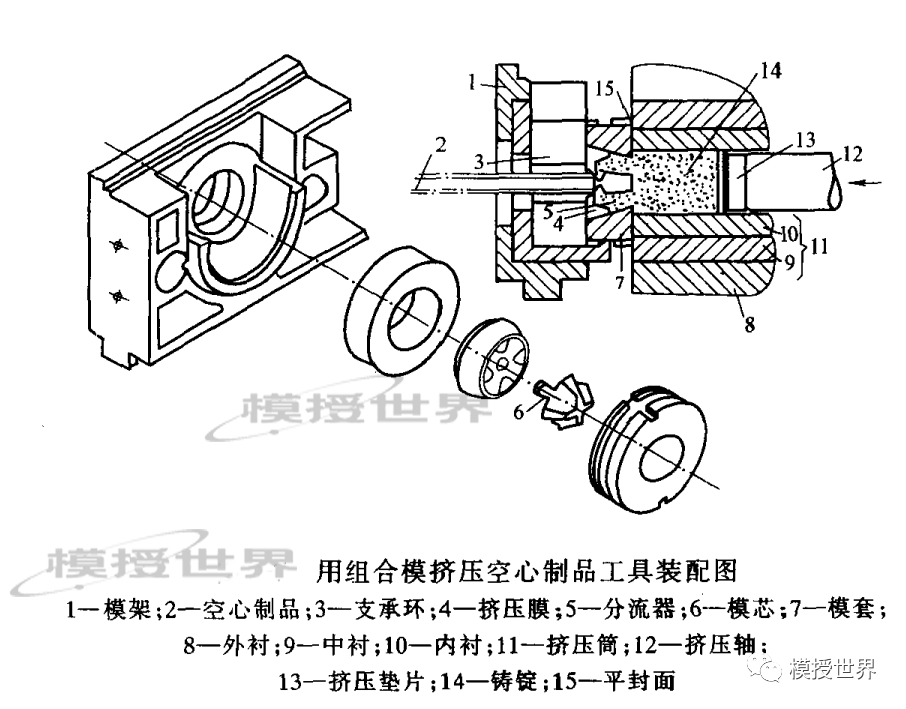

(4) Yamukela isakhiwo esihlanganisiwe, okungukuthi, ukwenza isikhunta sokuphambukisa, hlukanisa isikhunta esingaphezulu nesingezansi sesikhunta sokuphambukisa, futhi uhlukanise isikhunta ne-punch.

Ezinkulu zifa ngesimo esiyinkimbinkimbi nosayizi> 400mm kanye nezibhakela ezinobukhulu obuncane nobude obude, kungcono kakhulu ukwamukela isakhiwo esihlangene, ukwenza kube lula okuyinkimbinkimbi, ukunciphisa okukhulu kuya kokuncane, nokuguqula indawo yangaphakathi yesikhunta endaweni yangaphandle, okungeyona nje elula ukushisa nokupholisa ukucubungula.

Lapho uklama isakhiwo esihlanganisiwe, ngokuvamile kufanele siboliswe ngokuvumelana nezimiso ezilandelayo ngaphandle kokuphazamisa ukunemba kokufaneleka:

- Lungisa ukujiya ukuze ingxenye ephambanayo yesikhunta enezigaba ezihlukene kakhulu ifane ngokuyisisekelo ngemva kokubola.

- Ukubola ezindaweni lapho ukucindezeleka kulula ukukukhiqiza, uhlakaze ukucindezeleka kwakho, futhi uvimbele ukuqhekeka.

- Sebenzisana nembobo yenqubo ukuze wenze isakhiwo sibe ne-symmetrical.

- Ilungele ukucubungula okubandayo nokushisayo futhi kulula ukuyihlanganisa.

- Okubaluleke kakhulu ukuqinisekisa ukusebenziseka.

Njengoba kukhonjisiwe kuMfanekiso 4, iyifa elikhulu. Uma isakhiwo esibalulekile samukelwa, hhayi kuphela ukwelashwa kokushisa okuzoba nzima, kodwa futhi i-cavity izoncipha ngokungahambisani ngemva kokucisha, futhi ibangele ngisho nokungalingani kanye nokuhlanekezela kwendiza komkhawulo wokusika, okuzoba nzima ukulungisa ekucubunguleni okulandelayo. , ngakho-ke, isakhiwo esihlangene singamukelwa. Ngokomugqa wamachashazi kuMfanekiso 4, uhlukaniswe waba izingxenye ezine, futhi ngemva kokwelashwa kokushisa, ziyahlanganiswa futhi zenziwe, bese zigaywa futhi zifaniswe. Lokhu akugcini nje ukwenza lula ukwelashwa kokushisa, kodwa futhi kuxazulula inkinga ye-deformation.

Ingxenye.2 ukukhetha okulungile kwezinto

Ukuguqulwa kokwelashwa kokushisa kanye nokuqhekeka kuhlobene eduze nensimbi esetshenzisiwe kanye nekhwalithi yayo, ngakho-ke kufanele kusekelwe ezidingweni zokusebenza kwesikhunta. Ukukhethwa okunengqondo kwensimbi kufanele kucabangele ukunemba, isakhiwo kanye nobukhulu besikhunta, kanye nemvelo, ubuningi nezindlela zokucubungula izinto ezicutshungulwayo. Uma isikhunta esijwayelekile singenazo izidingo zokuguqulwa nokunemba, insimbi yensimbi ye-carbon ingasetshenziswa ngokwemibandela yokunciphisa izindleko; ezingxenyeni ezigogeke kalula neziqhekekile, insimbi yensimbi eyingxubevange enamandla aphakeme kanye nokucisha okubucayi okuhamba kancane kanye nesivinini sokupholisa singasetshenziswa; Isibonelo, i-electronic component die ekuqaleni yayisetshenziswa insimbi ye-T10A, ukuwohloka okukhulu futhi kulula ukuqhekeka ngemva kokucisha amanzi nokupholisa uwoyela, futhi umgodi wokucisha okugeza we-alkali akulula ukuwenza lukhuni. Manje sebenzisa insimbi engu-9Mn2V noma insimbi ye-CrWMn, ubulukhuni bokucisha nokuguqulwa kungahlangabezana nezidingo.

Kungabonakala ukuthi lapho ukuguqulwa kwesikhunta okwenziwe nge-carbon steel kungahlangabezani nezidingo, kusengabizi kakhulu ukusebenzisa insimbi ye-alloy njengensimbi ye-9Mn2V noma i-CrWMn steel. Nakuba izindleko zezinto ezibonakalayo ziphakeme kancane, inkinga yokuguqulwa nokuqhekeka iyaxazululwa.

Ngenkathi kukhethwa izinto ngendlela efanele, kuyadingeka futhi ukuqinisa ukuhlolwa nokuphathwa kwezinto ezingavuthiwe ukuvimbela ukuqhekeka kokwelashwa kokushisa kwesikhunta ngenxa yokukhubazeka kwempahla eluhlaza.

Ihlelwe nguMay Jiang evela kwaMAT Aluminium

Isikhathi sokuthumela: Sep-16-2023